Feeding mechanism of yarn switcher

A thread device and yarn feeding technology, which is applied in the field of knitting machine thread changer, can solve problems such as high yarn feeding point and unstable yarn feeding, and achieve the effects of improving production efficiency, simple structure, and meeting the needs of yarn feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

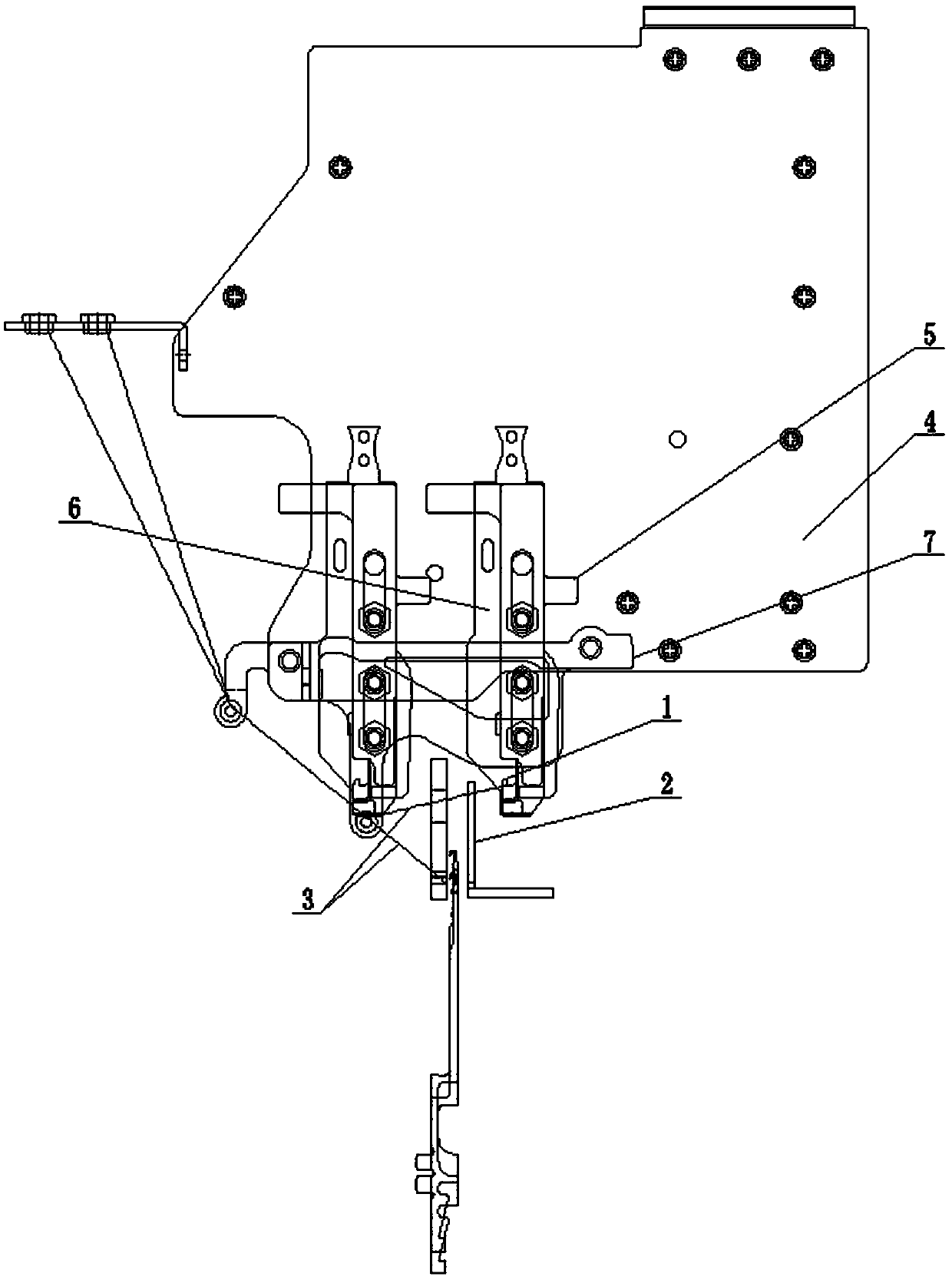

[0035] see figure 1 , in the prior art, the yarn clamping and cutting device 5 on the main body 4 of the yarn changer is controlled by the controller to move horizontally, and the yarn 3 to be replaced is introduced into the knitting area to form the first yarn feeding point 1, and is passed through the knitting machine. The first yarn pressing plate 2 is pressed into or introduced into the knitting needles to participate in weaving.

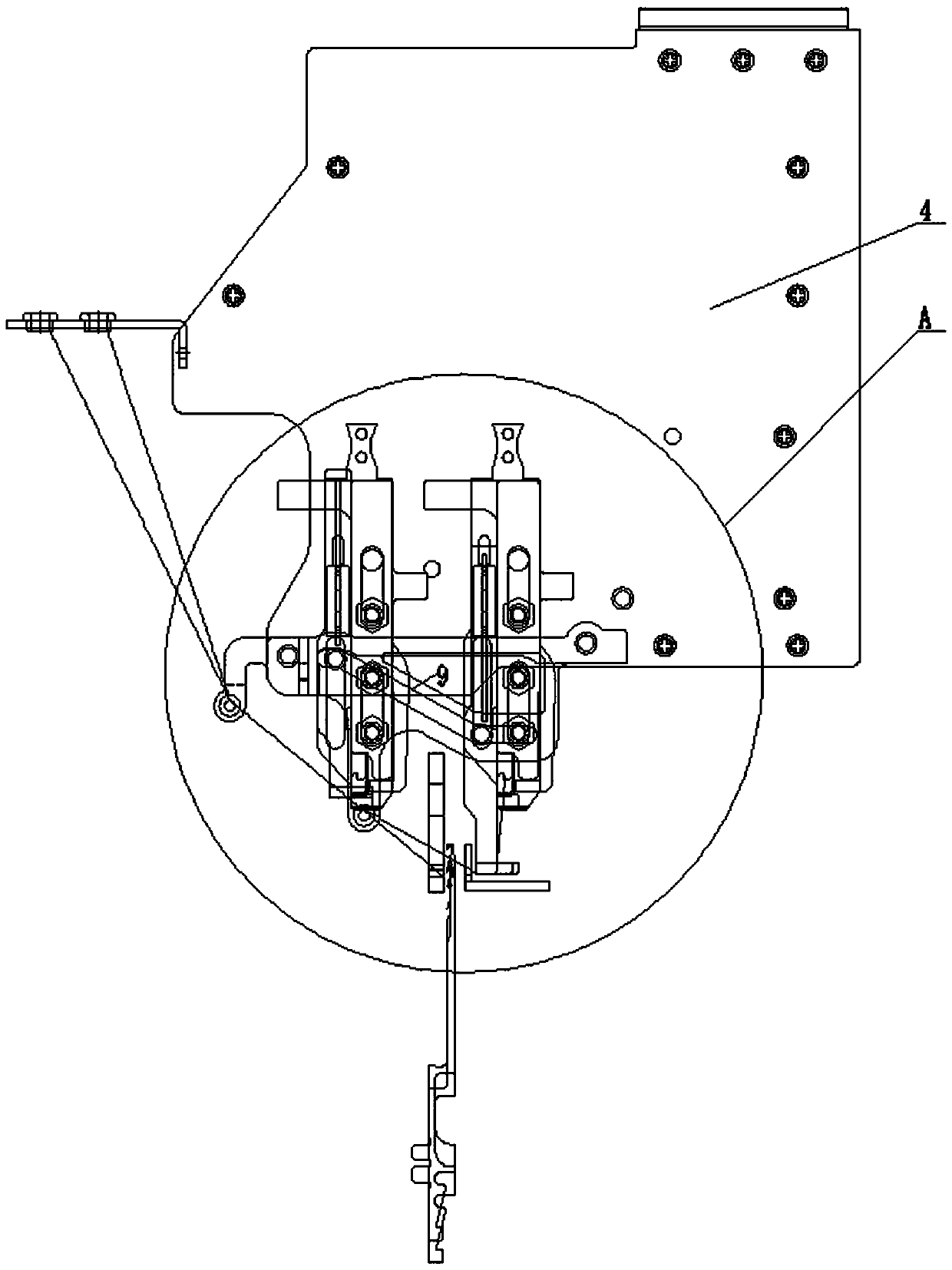

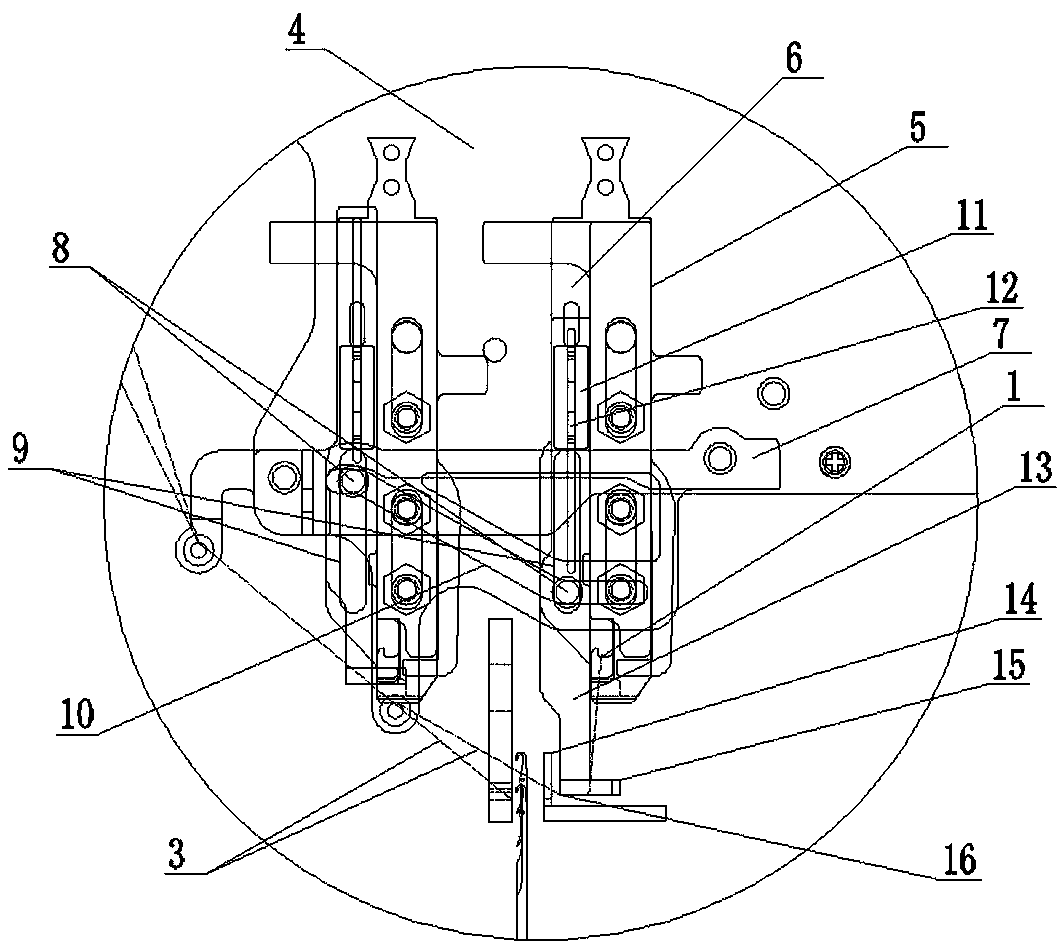

[0036] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com