Yarn conveying device of knitting loom

A technology of a yarn feeding device and a knitting machine, which is applied in the field of knitting machines, can solve the problems of unstable yarn tension, poor product quality, and uneven cloth surface, and achieve better cloth surface effect, stable yarn length, and clear cloth surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

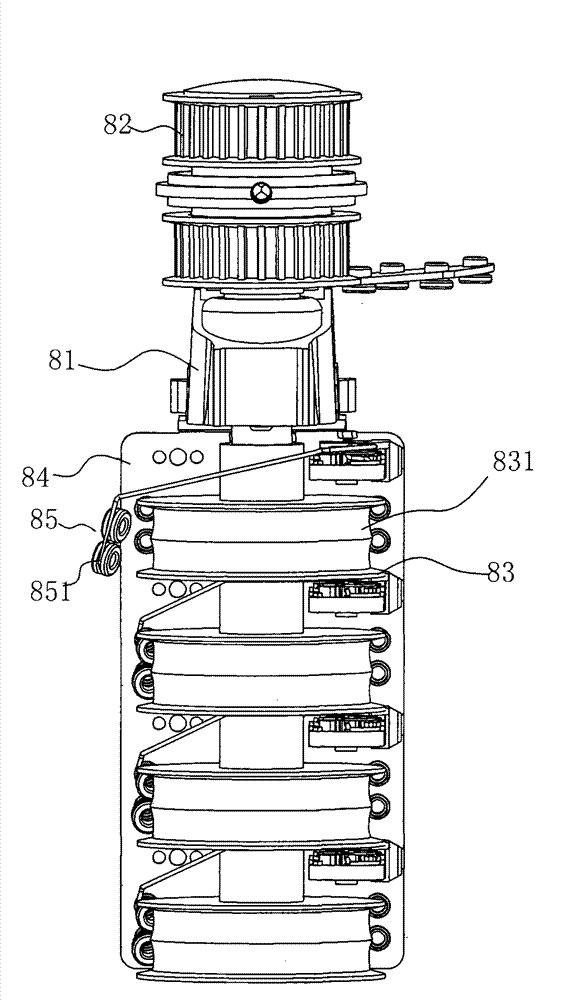

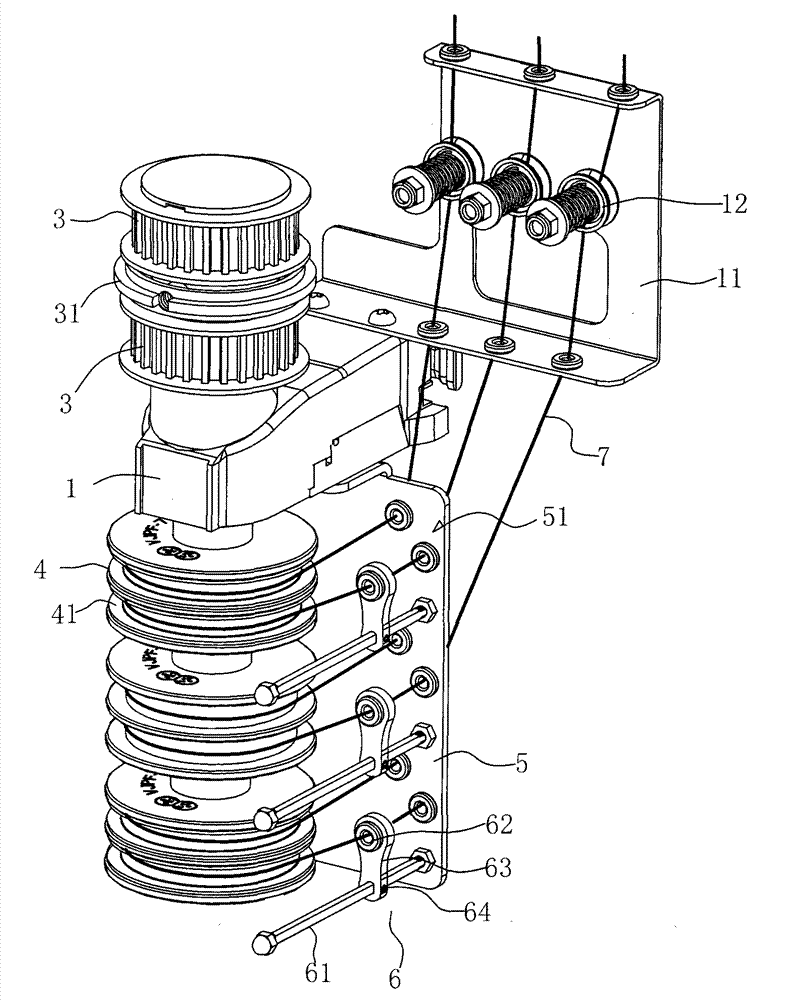

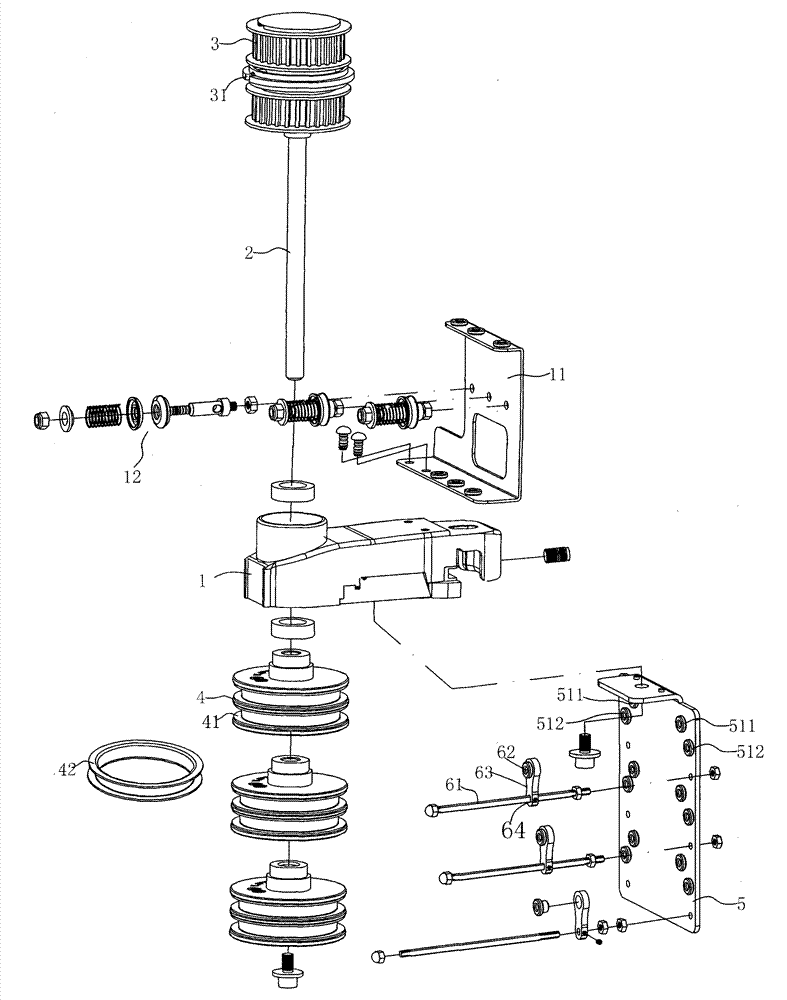

[0031] See figure 2 , 3 , The present invention includes: a fixed seat 1, a rotating shaft 2, a driving wheel 3, a yarn feeding wheel 4, a yarn threading plate 5 and a tension regulator 6. Wherein, the rotating shaft 2 is arranged on the fixed seat 1, and several driving wheels 3 are arranged on its upper end, and the yarn feeding wheel 4 is arranged on the lower section where the rotating shaft 2 is located at the fixed seat 1. The drive wheel 3 driven by the belt drives the yarn delivery wheel 4 to rotate together through the rotating shaft 2 , and a clutch 31 is arranged between each drive wheel 3 .

[0032] The yarn feeding wheel 4 is provided with several yarn guide grooves 41, and the bottom surface of the yarn guide grooves 41 is a slope with a large upper part and a smaller lower part, such as Figure 4 shown. In addition, in order to increase wear resistance, a wear-resistant apron 42 is set on the yarn guide groove 41 of the yarn delivery wheel 4. During installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com