Detergent box and washing machine with the same

A detergent box and detergent technology, applied to other washing machines, washing devices, household appliances, etc., can solve the problem of liquid residue and achieve the effect of avoiding the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

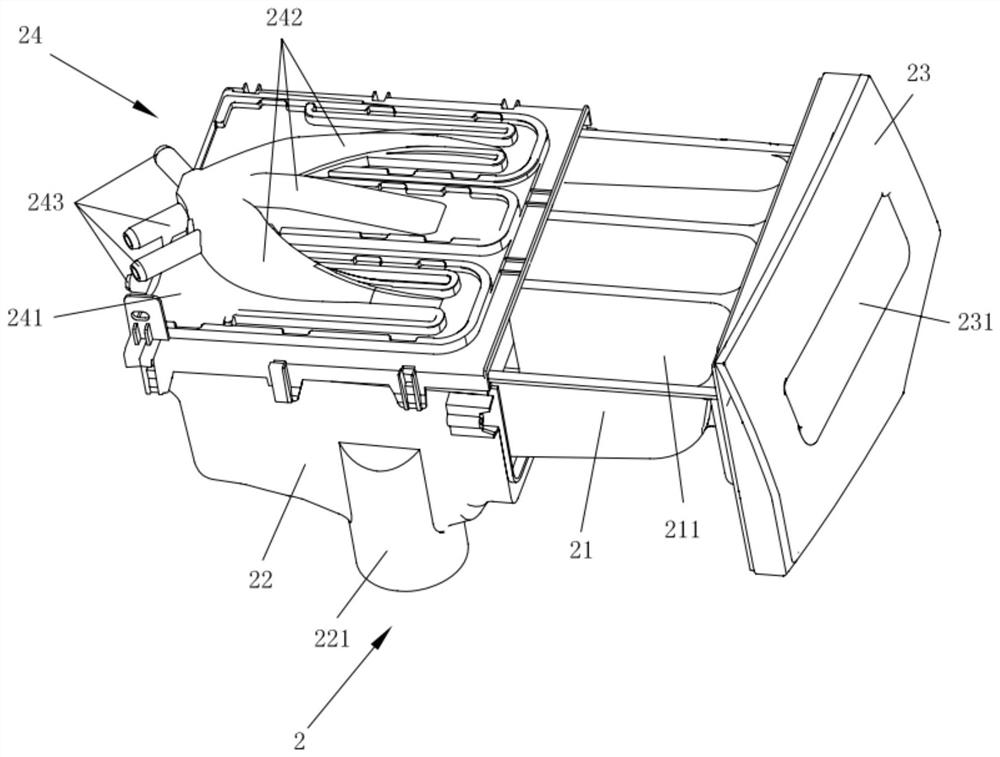

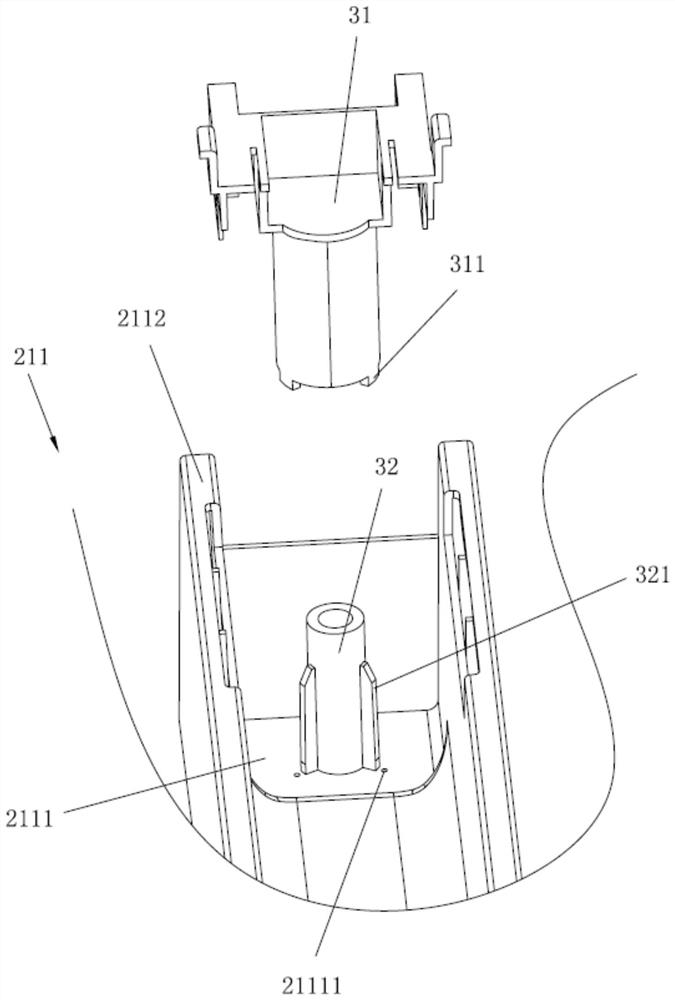

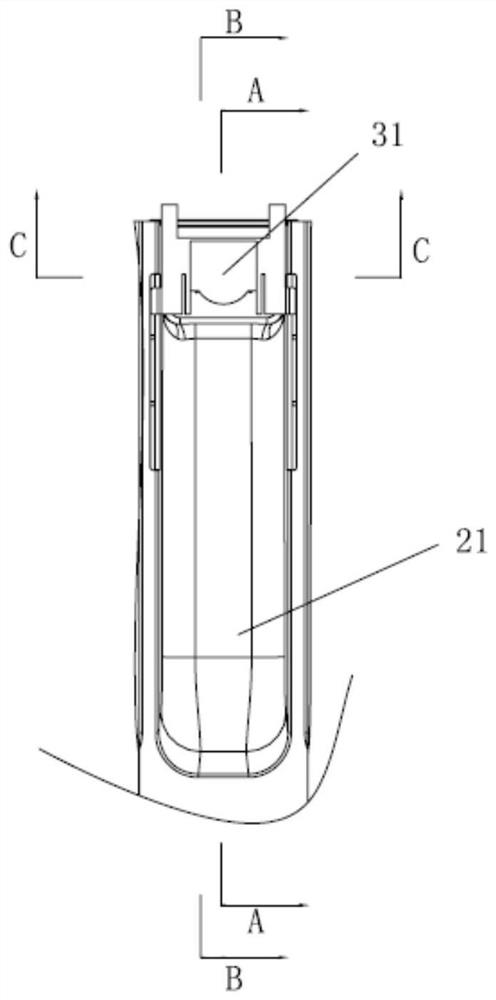

[0040] This embodiment provides a detergent box, such as Figures 1 to 5 As shown, the detergent box includes a detergent containing space 2 , a siphon assembly 3 , a residual liquid channel 4 and a quality block 5 . in,

[0041] Detergent containing space 2 is used to hold liquid detergent. Such as figure 1 As shown, the detergent containing space 2 includes a water collecting cavity 22 fixed to the washing machine body, a spray assembly 24 fastened to the water collecting cavity 22 and fixed to the washing machine body, and one end extends into the water collecting cavity The detergent box body 21 inside the body 22 and can slide relative to the spray assembly 24 .

[0042] Specifically, the washing box body 21 is provided with a pulley assembly, and the spray assembly 24 is provided with a guide rail at a position corresponding to the pulley assembly, and the pulling of the washing box body 21 is realized through the cooperation of the pulley assembly and the guide rail....

Embodiment 2

[0061] The difference between this embodiment and the first embodiment lies in that the direction of the central axis of the residual liquid discharge channel 4 is different.

[0062] Specific reference Figure 9 , the residual liquid discharge channel 4 is arranged along the X direction, and the corresponding mass block 5 reciprocates along the X direction, and the residual liquid in the detergent box is sent into the outer cylinder of the washing machine by the vibration of the washing machine along the X direction.

[0063] In this embodiment, other structures of the detergent box are the same as those in Embodiment 1, and will not be repeated here.

[0064] This embodiment also provides a washing machine, including a washing machine body and the above-mentioned detergent box connected to the washing machine body.

Embodiment 3

[0066] The difference between this embodiment and Embodiment 1 and Embodiment 2 lies in that the direction of the central axis of the residual liquid discharge channel 4 is different.

[0067] Specific reference Figure 10 , the residual liquid discharge channel 4 is arranged along the Y direction, and the corresponding mass block 5 reciprocates along the Y direction, and the residual liquid in the detergent box is sent into the outer cylinder of the washing machine by the vibration of the washing machine along the Y direction.

[0068] In this embodiment, other structures of the detergent box are the same as those in Embodiment 1, and will not be repeated here.

[0069] This embodiment also provides a washing machine, including a washing machine body and the above-mentioned detergent box connected to the washing machine body.

[0070] One end of the second channel 42 away from the first channel 41 is also provided with a one-way valve (not shown in the figure). flow, not ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com