A design method of curved anchor lip

A design method, anchor lip technology, applied to anchor points, ship construction, ship components, etc., can solve problems such as lightening and shortening the test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

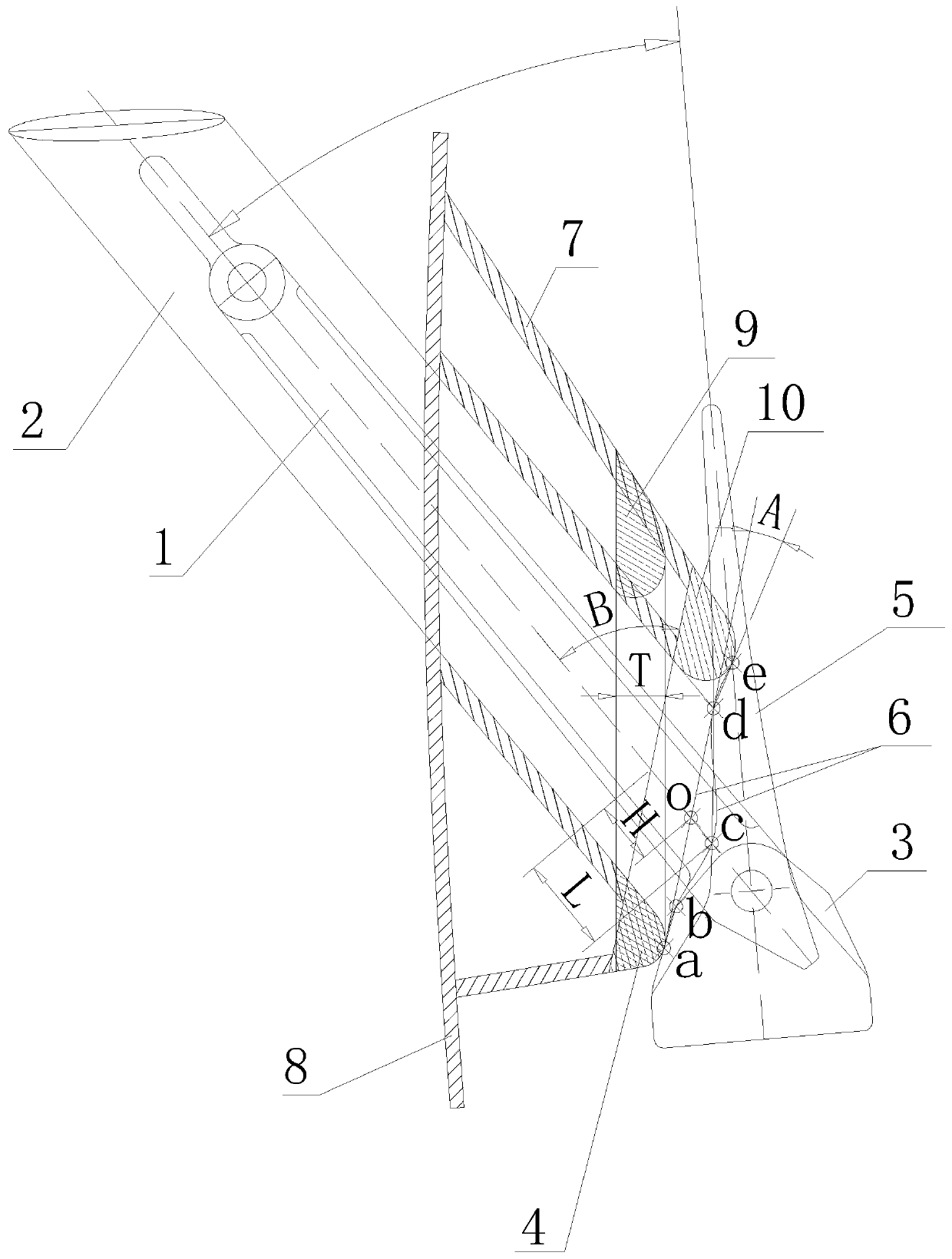

[0030] Such as Figure 1-3 As shown, this embodiment provides a method for designing a curved anchor lip, including the following steps:

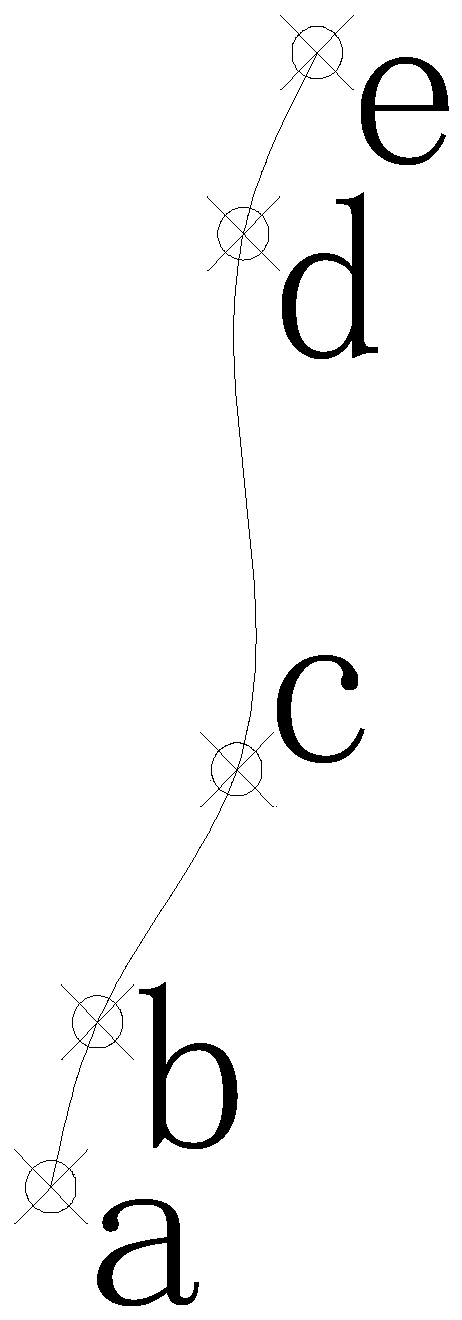

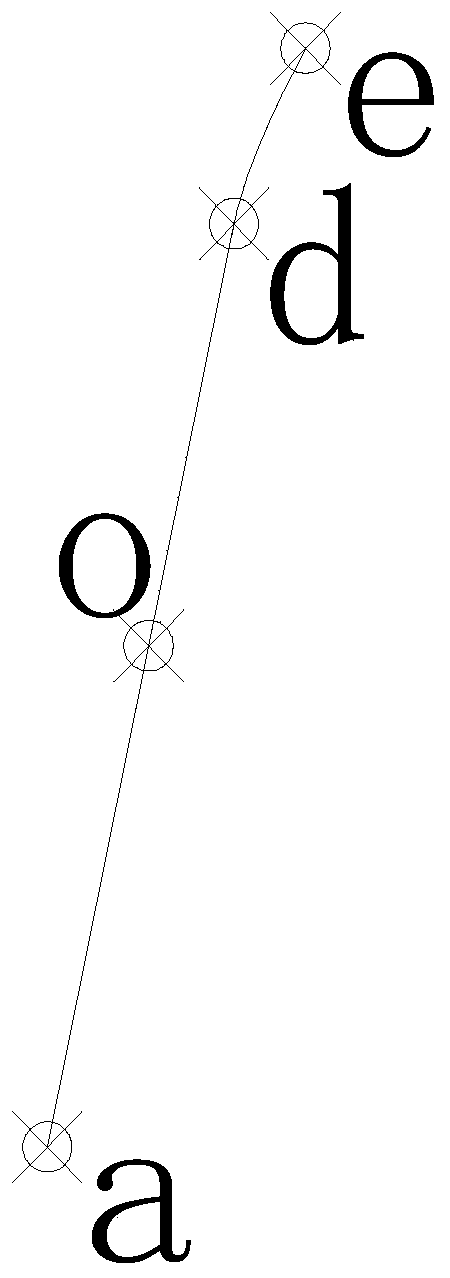

[0031] 1) On the preliminary design drawing, rotate the anchorage outward to the full angle with the center of the rotating shaft as the center, suspend the anchor rod 1 in the center of the anchor chain barrel 2, and move it up and down along the center line of the anchor chain barrel 2. The auxiliary anchorage stops when the anchor crown 3 just touches the lower mouth 4 of the anchor lip, and the contact a between the anchor crown 3 and the anchor lip is obtained;

[0032] 2) Set the upper break point of the contour line of the anchor crown 3 as point b, and set the intersection point of the contour line of the anchor fluke 5 and the center line of the anchor chain barrel 2 as point c;

[0033] 3) Set the intersection point of the contour line of the anchor fluke 5 and the extension line of the inner edge of the upper opening of the anch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com