Ceramic silicone rubber cable vulcanization process

A technology of ceramic silicone rubber and cables, which is applied in the manufacture of cables/conductors, electrical components, circuits, etc., and can solve problems such as difficult vulcanization of ceramic silicone rubber cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

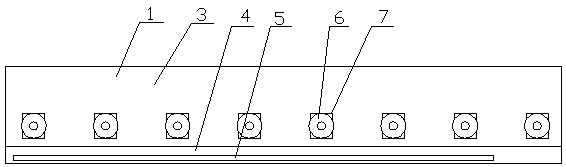

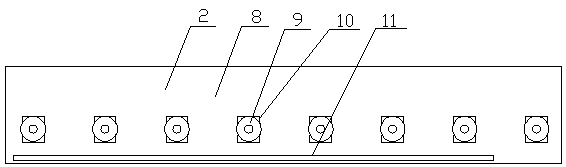

[0014] Ceramic silicone rubber cable vulcanization process, the specific steps are as follows:

[0015] (1) The conductor, the low-smoke, halogen-free insulating layer armor layer and the low-smoke, halogen-free inner sheath are sequentially processed into cables from the inside to the outside, and then sent to the steam water tank for vulcanization, and the cables are Pass through the steam water tank 1 at a constant speed of 300m / h; the temperature of the steam is the boiling point temperature of the water in the water tank.

[0016] (2) The cable vulcanized by the steam water tank is sent to the electric drying tunnel 2 for vulcanization. The cable passes through the electric drying tunnel at a constant speed of 300m / h, and the temperature of the electric drying tunnel is 90-92°C.

[0017] The steam water tank 1 has three sections, and each section of the steam water tank 1 is 2.5 to 3 meters long, preferably 3 meters.

[0018] The electric drying tunnel 2 is two sections,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com