Rubber V-belt round mould vulcanizing device

A round mold and rubber technology, applied in belts, other household appliances, household appliances, etc., can solve problems such as energy waste, save steam, ensure the quality of vulcanization molding, and reduce energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

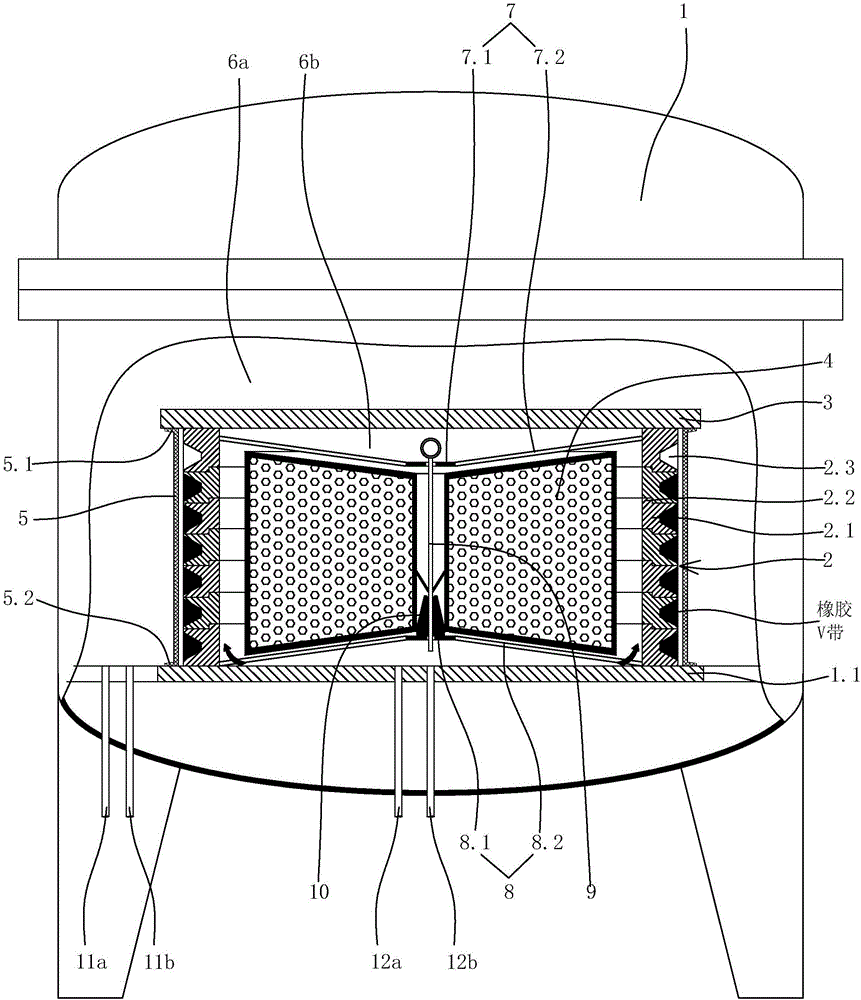

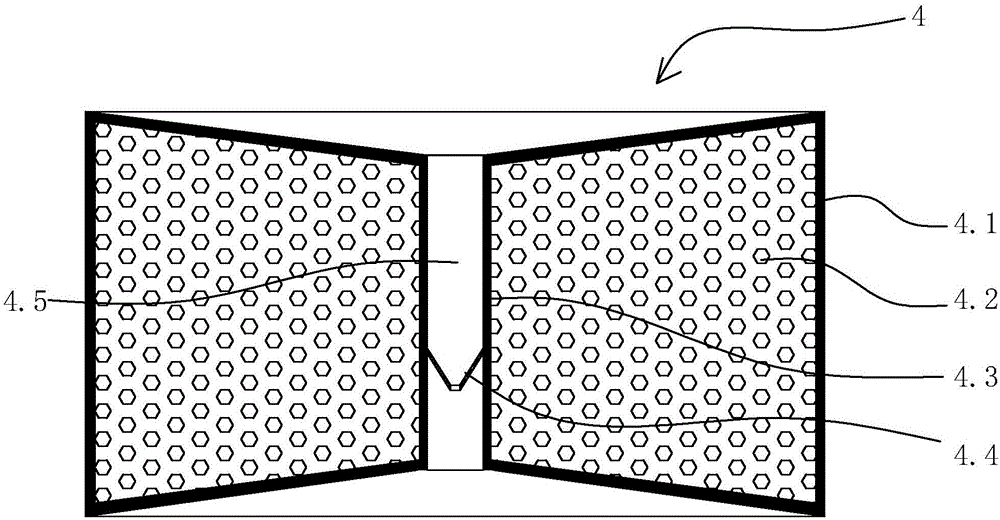

[0045] Embodiment 1: as figure 1 As shown, a rubber V-belt round mold vulcanization device includes: a vulcanization tank 1, a V-belt vulcanization mold sleeve 2, a vulcanization sealing rubber sleeve 5 set outside the V-belt vulcanization mold sleeve, a mold sealing cover plate 3 and a steam-saving Energy saving parts4. The bottom of the cavity of the vulcanization tank is provided with a support plate 1.1.

[0046] The lower end surface of the V-belt vulcanization die sleeve is supported on the upper surface of the supporting plate. The axis of the V-belt vulcanization mold sleeve is set vertically. The outer surface of the V-belt vulcanization die sleeve is provided with a number of annular V-belt forming grooves 2.3 distributed sequentially from bottom to top. The V-belt vulcanization die sets include sequentially distributing individual die sets 2.1 from bottom to top and a die set connection structure connecting the individual die sets. The annular V-belt forming gro...

Embodiment 2

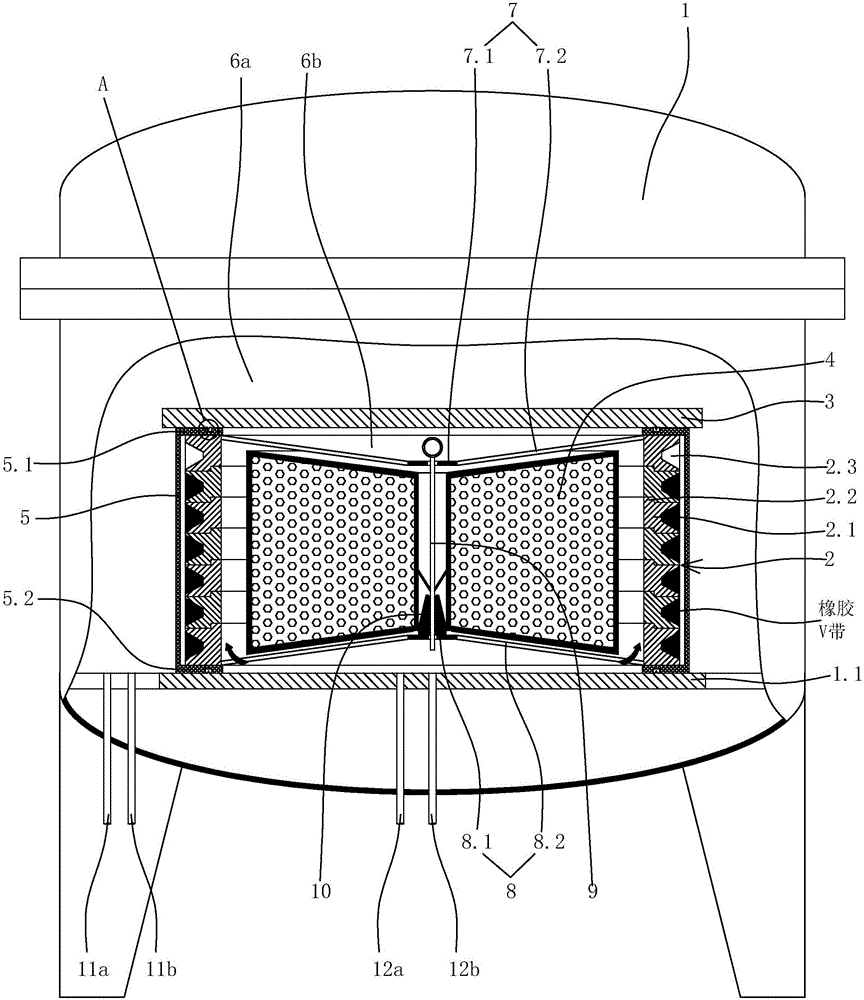

[0064] Embodiment 2: the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

[0065] Such as image 3 , Figure 4 As shown, the upper end of the vulcanized sealing rubber sleeve 5 is provided with an annular upper sealing sheet 5.1 extending inward, that is, the upper end of the vulcanized sealing rubber sleeve is provided with an annular upper sealing sheet extending into the vulcanized sealing rubber sleeve. The annular upper sealing piece is located between the upper end surface of the V-belt vulcanization mold sleeve and the mold sealing cover plate, and the annular upper sealing piece forms a sealing structure between the upper end surface of the V-belt vulcanization mold sleeve and the mold sealing cover plate.

[0066] The lower end of the vulcanized sealing rubber sleeve is provided with an annular lower sealing sheet 5.2 extending inward, that is, the lower end of the vulcanized sealing rubber sleeve is provided with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com