A forged steel bonnetless globe valve

A technology of stop valve and bonnet, which is applied in the direction of lifting valve, valve details, valve device, etc., can solve the problems of sealing leakage and poor safety of the connection between the valve body and bonnet, improve safety and reliability, and solve the problem of missing upper seal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

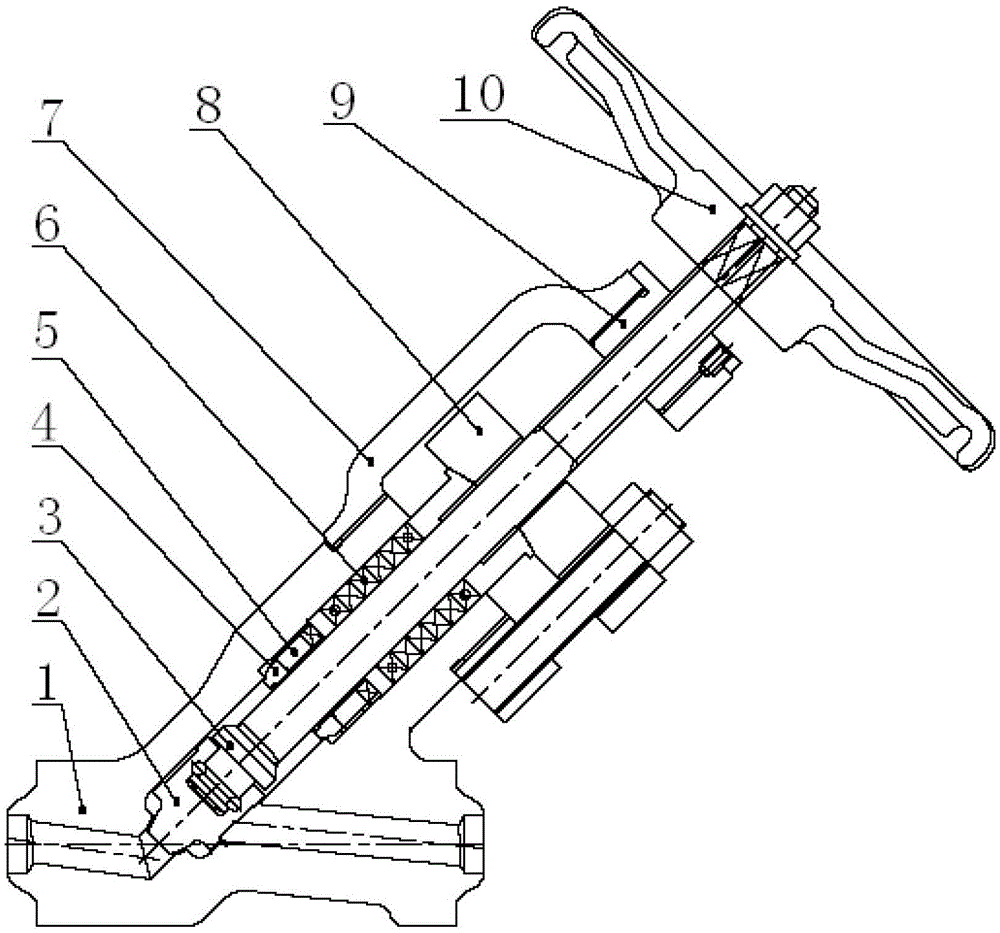

[0014] Such as figure 1 As shown, a forged steel bonnetless globe valve includes a valve body 1, the interior of the valve body 1 is a cavity structure, a valve stem assembly 3 is installed in the cavity of the valve body 1, and the head of the valve stem assembly 3 fixes the valve disc 2. The valve stem assembly 3 is also sequentially fitted with a sealing seat 4, a pressure ring 5 and a packing 6. A bracket 7 is connected to the valve body 1. A packing gland assembly 8 is connected to the bracket 7. The end of the bracket 7 is connected to a The valve stem nut 9 and the valve stem assembly 3 pass through the bracket 7 , the packing gland assembly 8 and the valve stem nut 9 in turn, and the end of the valve stem assembly 3 is connected with a handwheel 10 .

[0015] Since the present invention has no valve cover and no sealing member connecting the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com