A double-cone sealing structure for safety valve and its application

A technology of cone sealing and safety valve, which is applied in the direction of safety valve, balance valve, valve device, etc. It can solve the problems of small deformation of sealing block at low temperature, leakage of safety valve, insufficient sealing specific pressure, etc., and achieve the increase of sealing specific pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 0.1MPa~5MPa low pressure condition

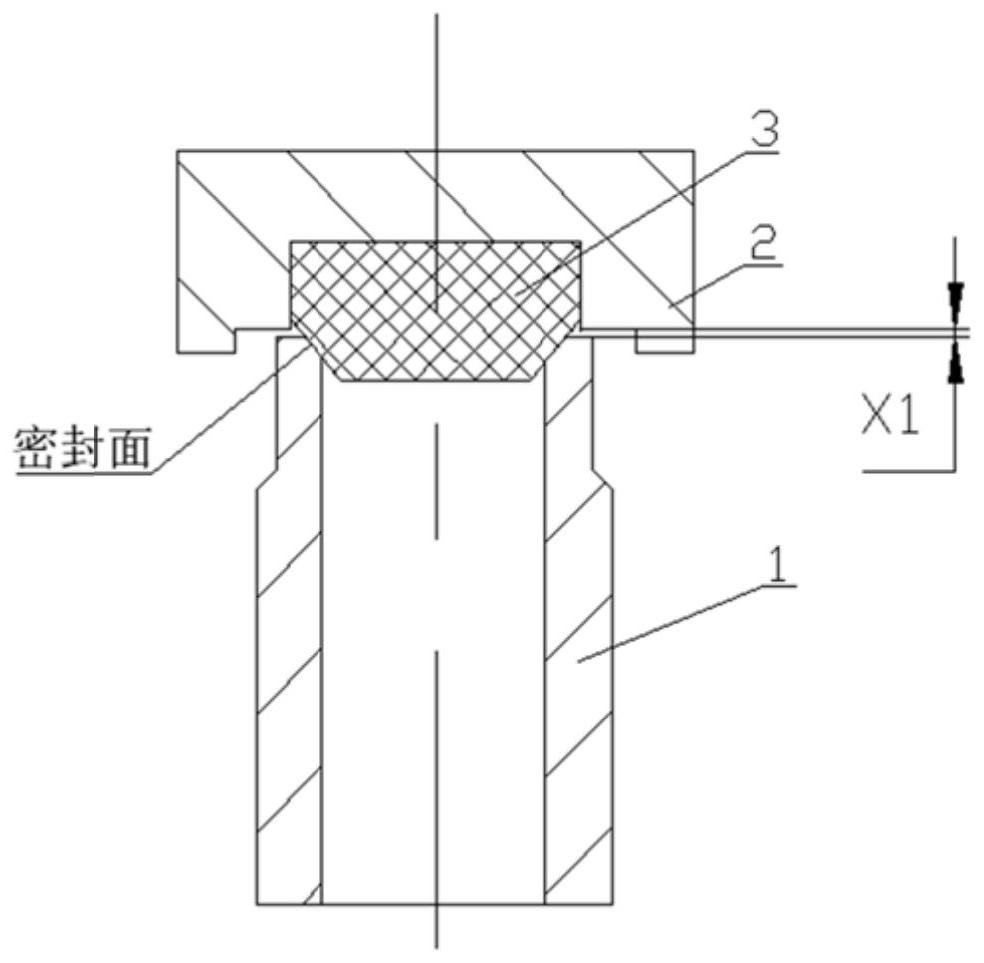

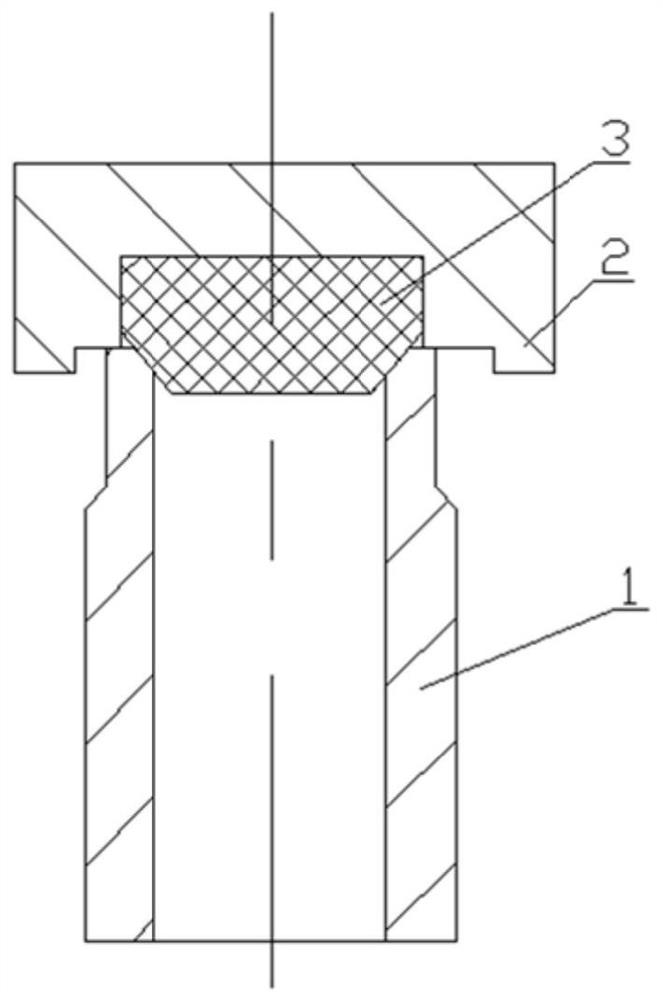

[0043] A double-cone sealing structure for a safety valve, comprising a valve seat 1, a recoil disc 2 and a sealing block 3, the valve seat 1 is a hollow boss structure, and the top of the hollow cavity is machined with an annular conical surface with a large end facing upwards. The conical surface forms a second sharp angle 6 on the upper surface of the valve seat; the sealing block 3 is located between the valve seat 1 and the recoil plate 2, and is fixed on the recoil plate 2 by screws. The lower end of the sealing block 3 is processed with two different Angled cone surface, the cone angle α (35°) of the first cone surface is smaller than the cone angle β (65°) of the second cone surface, the intersection of the first cone surface and the second cone surface forms a first sharp angle 5, the initial When sealing, the first sharp angle 5 is in contact with the annular cone surface on the valve seat 1 for sealing. When ...

Embodiment 2

[0048] Example 2 Medium and high pressure working conditions above 5MPa

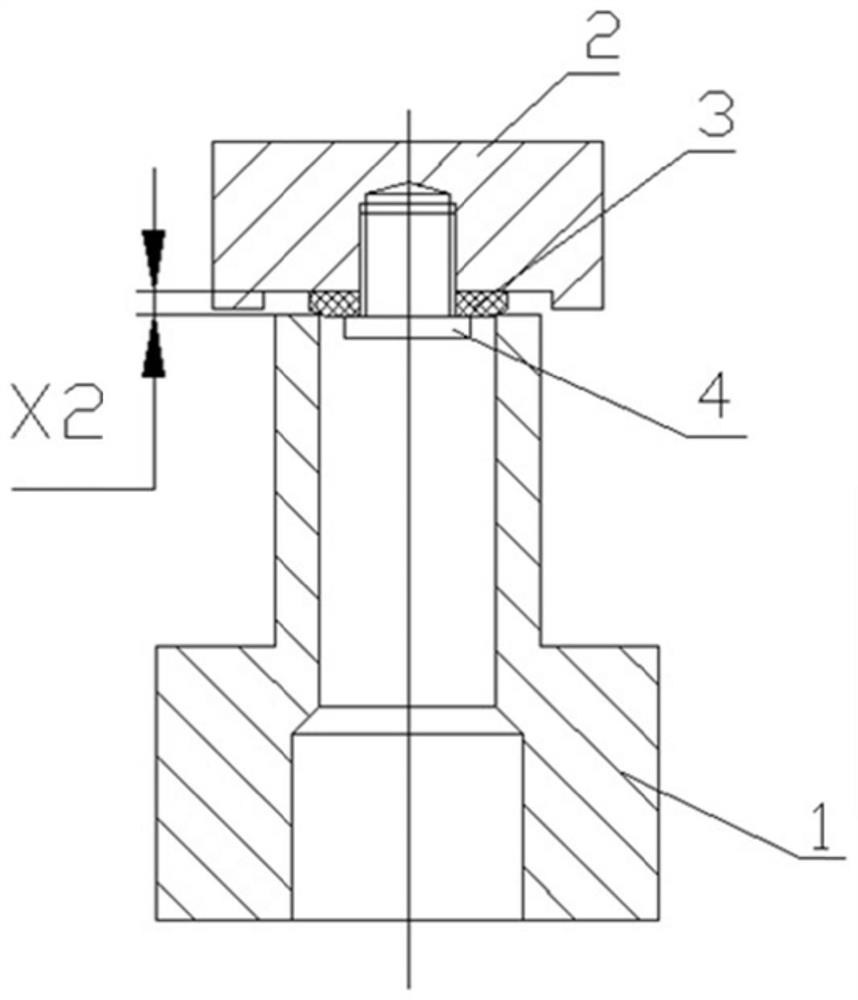

[0049] A double-cone sealing structure for a safety valve, comprising a valve seat 1, a recoil disc 2 and a sealing block 3, the valve seat 1 is a hollow boss structure, and the top of the hollow cavity is machined with an annular conical surface with a large end facing upwards. The conical surface forms a second sharp angle 6 on the upper surface of the valve seat; the sealing block 3 is located between the valve seat 1 and the recoil plate 2, and is fixed on the recoil plate 2 by screws. The lower end of the sealing block 3 is processed with two different Angled cone surface, the cone angle α (30°) of the first cone surface is smaller than the cone angle β (70°) of the second cone surface, the intersection of the first cone surface and the second cone surface forms a first sharp angle 5, the initial When sealing, the first sharp angle 5 is in contact with the annular cone surface on the valve seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com