Integrated multi-probe layered scanning high-precision measuring probe structure

A layered scanning and multi-probe technology, which is applied in the direction of measuring devices, analyzing materials, and material analysis through electromagnetic means, can solve the problem of uneven outer diameter of measuring probes, deformation of outer plastic casings, unstable dielectric constants, etc. problems, to achieve the effect of excellent mechanical strength, extended service life, excellent mechanical properties and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

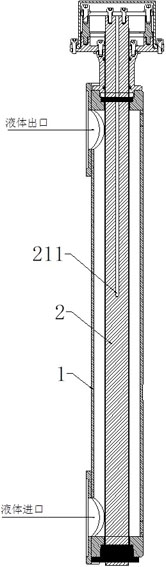

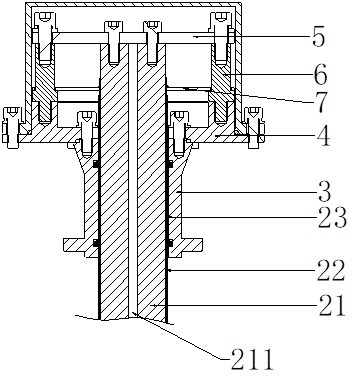

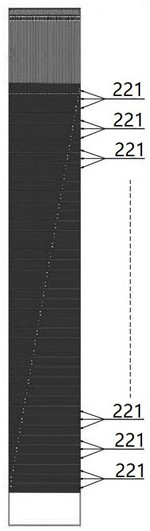

[0024] Such as figure 1 As shown, the integrated multi-probe layered scanning high-precision measuring probe structure includes the measuring probe 2 extending into the measuring pipe 1, the measuring probe 2 and the measuring pipe 1 are concentrically arranged, and the joints are equipped with sealing rings 3 For sealing, the sealing ring 3 is specifically a fluorine rubber Y-ring. The measuring probe 2 is composed of a ceramic rod 21, a double-sided flexible copper-clad laminate 22, and a plastic insulating sleeve 23. The ceramic rod 21 is connected to the double-sided flexible copper-clad laminate 22, and the double-sided flexible copper-clad A plastic insulating sleeve 23, the plastic insulating sleeve 23 can isolate the measured liquid from the double-sided flexible copper clad laminate 22. Specifically, ceramics have the characteristics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com