Spraying hole valve for shower head

A spray hole and shower technology, applied in the field of spray hole valve, can solve the problems of low water temperature, discomfort, prolonged wiping time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

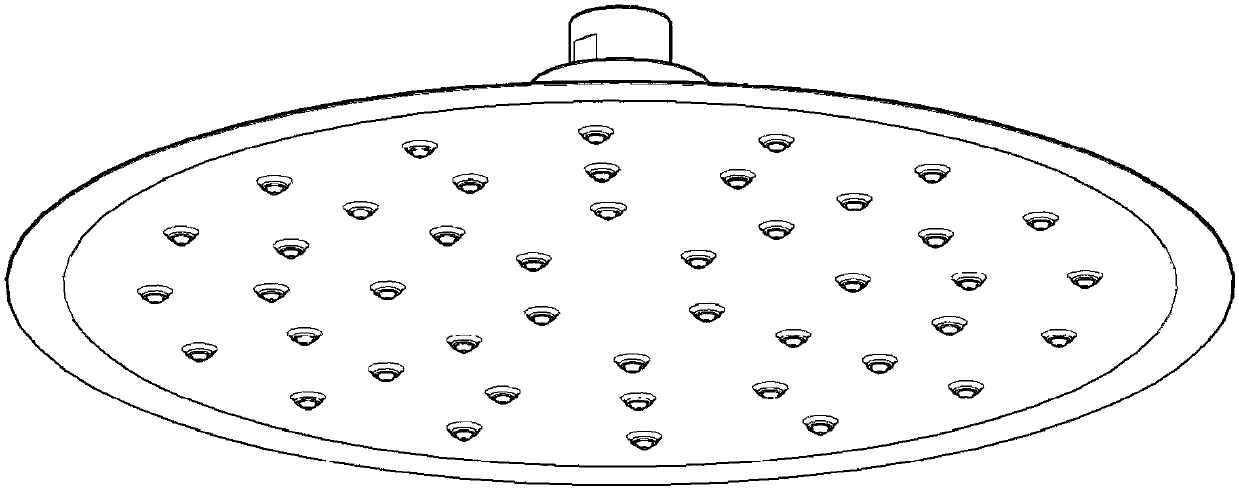

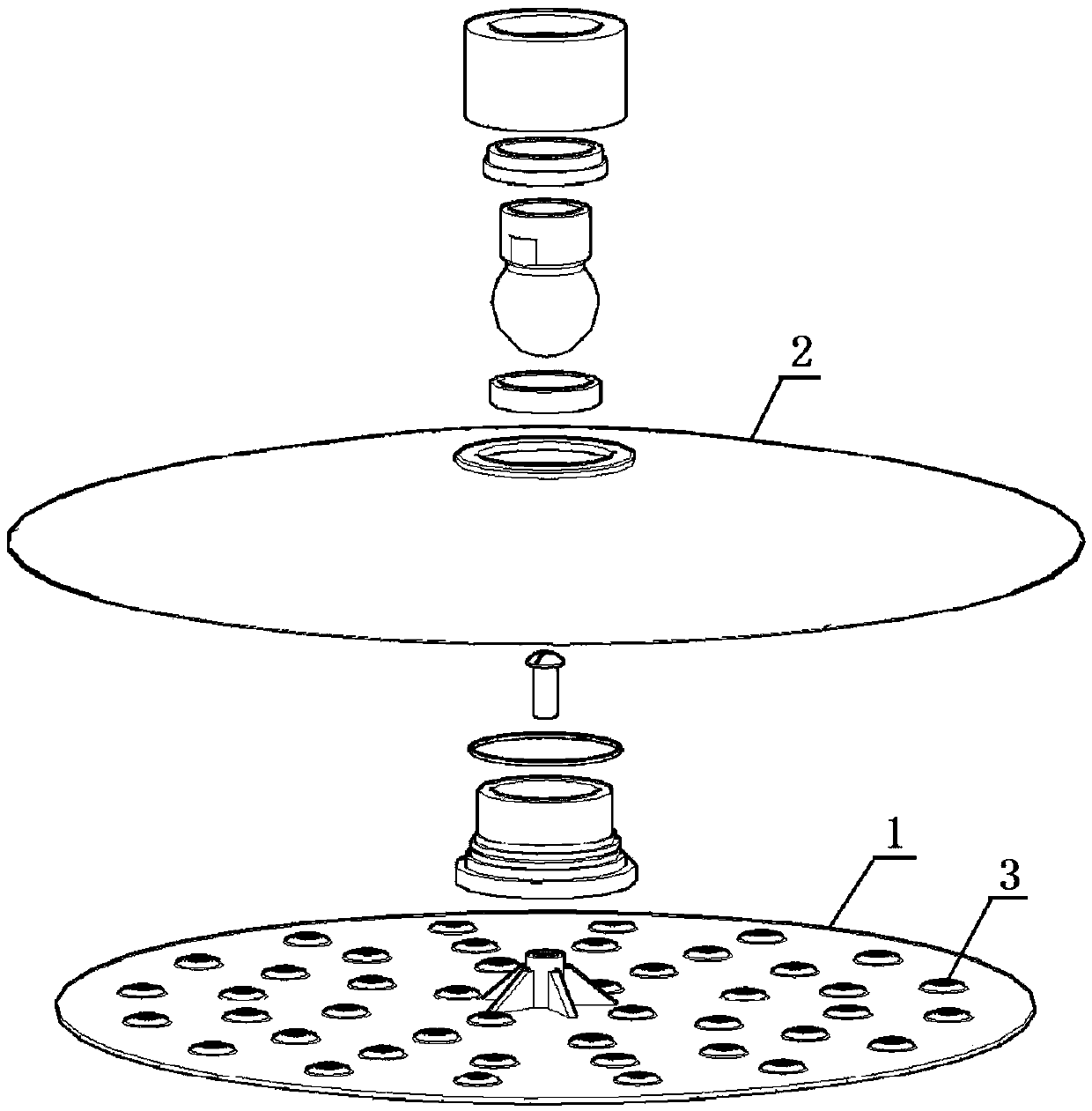

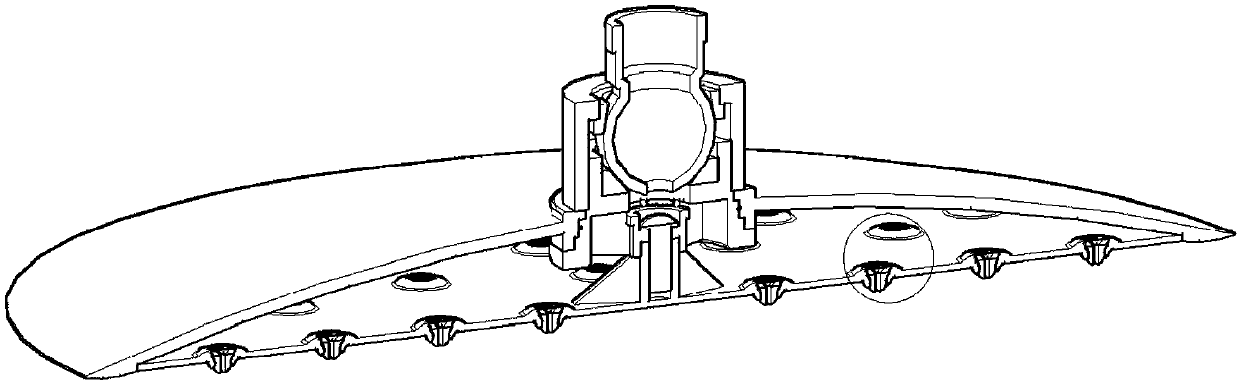

[0017] like Figure 1 to Figure 6 As shown, a shower is mainly composed of a front cover 1 and a rear cover 2, and the front cover and the rear cover are fastened together to form a water storage chamber. The front cover is provided with spray holes, and a spray hole valve 3 is arranged in each spray hole; the outer wall of the spray hole valve and the inner wall of the spray hole form a tight fit, and the spray hole valve is provided with a hole through the spray hole valve. Water spray hole, the end of the water spray hole near the water storage chamber is a conical hole 31 with a large water inlet and a small water outlet, and the end near the water outlet is a cylindrical hole 32 with the cone top of the conical hole as the diameter. When the shower is turned on, the water flow enters the water storage cavity, and then sprays out from the spray hole.

[0018] The wall surface of the water spray hole facing the water storage chamber is covered with an elastic valve plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com