Dual-row battery pack

A technology of battery packs and batteries, which is applied in the use/maintenance of primary batteries, secondary batteries, battery pack components, etc., and can solve the problem that the battery pack cannot be effectively fixed, the battery heat cannot be effectively cooled, and the use of the battery can be reduced. Life and other issues, to avoid poor spot welding or desoldering, suitable for popularization and use, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

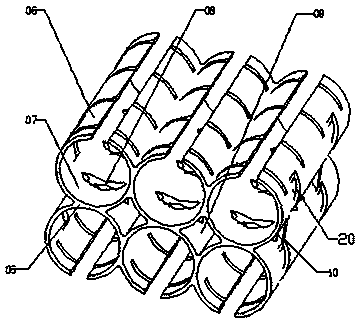

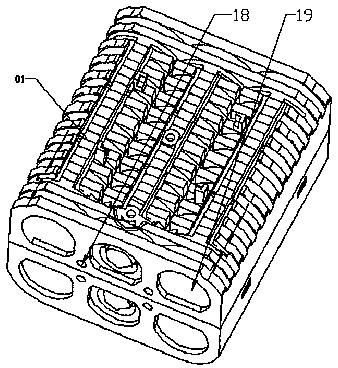

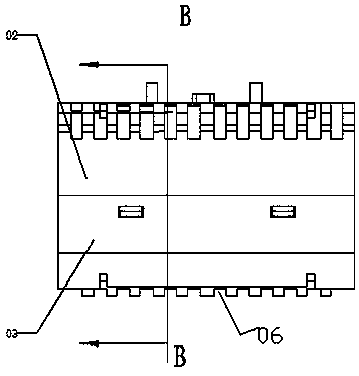

[0027] Refer to attached Figure 1-11 , a double-row battery pack, which includes a bracket 04 and a bracket fixing seat 01; the bracket 04 includes a bracket plate 05, and the upper and lower sides of the bracket plate 05 are evenly provided with a number of 1# battery containing grooves 07, 1# battery containing grooves 07 Through the two ends of the bracket plate 05, a number of elastic sheets 06 are symmetrically arranged on both sides of the 1# battery containing groove 07, and there are gaps between the elastic sheets 06 on the same side. The elastic sheets 06 are arc-shaped, and the elastic sheets 06 A circular through hole is formed between the 1# battery containing groove 07, and a gap is provided between the elastic sheets 06 on both sides of the symmetry, and a strip-shaped opening is formed between the gaps; the bracket fixing seat 01 includes a support upper bottom plate 02, a support The lower base plate 03, the upper base plate 02 of the support, and the lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com