Horizontal universal adjusting device

A universal adjustment and leveling technology, applied in workbenches, manufacturing tools, etc., can solve the problems of difficult to meet adjustment requirements, complicated operation, low precision, etc., and achieve the effects of convenient use and adjustment, compact overall structure and high adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the drawings and an embodiment of the present invention. It should be noted that the embodiment described here is only an embodiment for illustrating and explaining the present invention, and not for limiting the present invention.

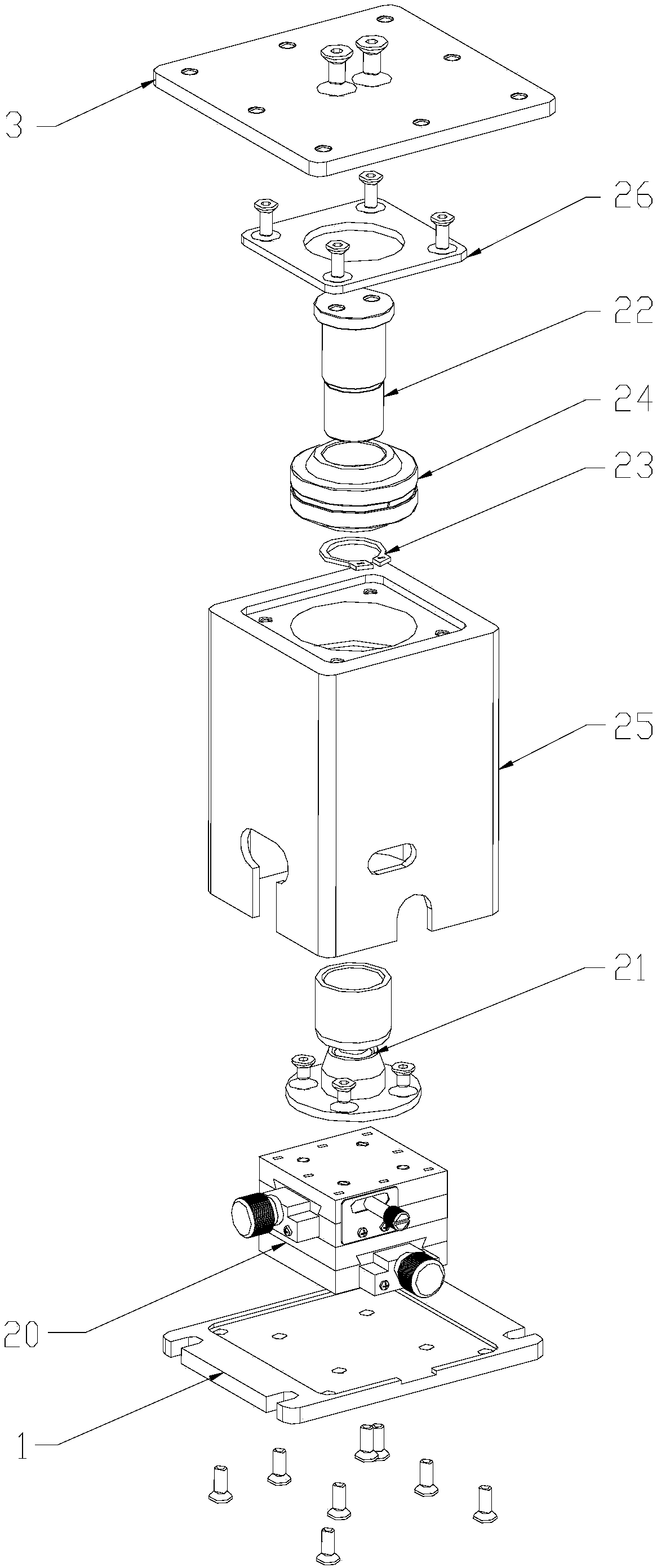

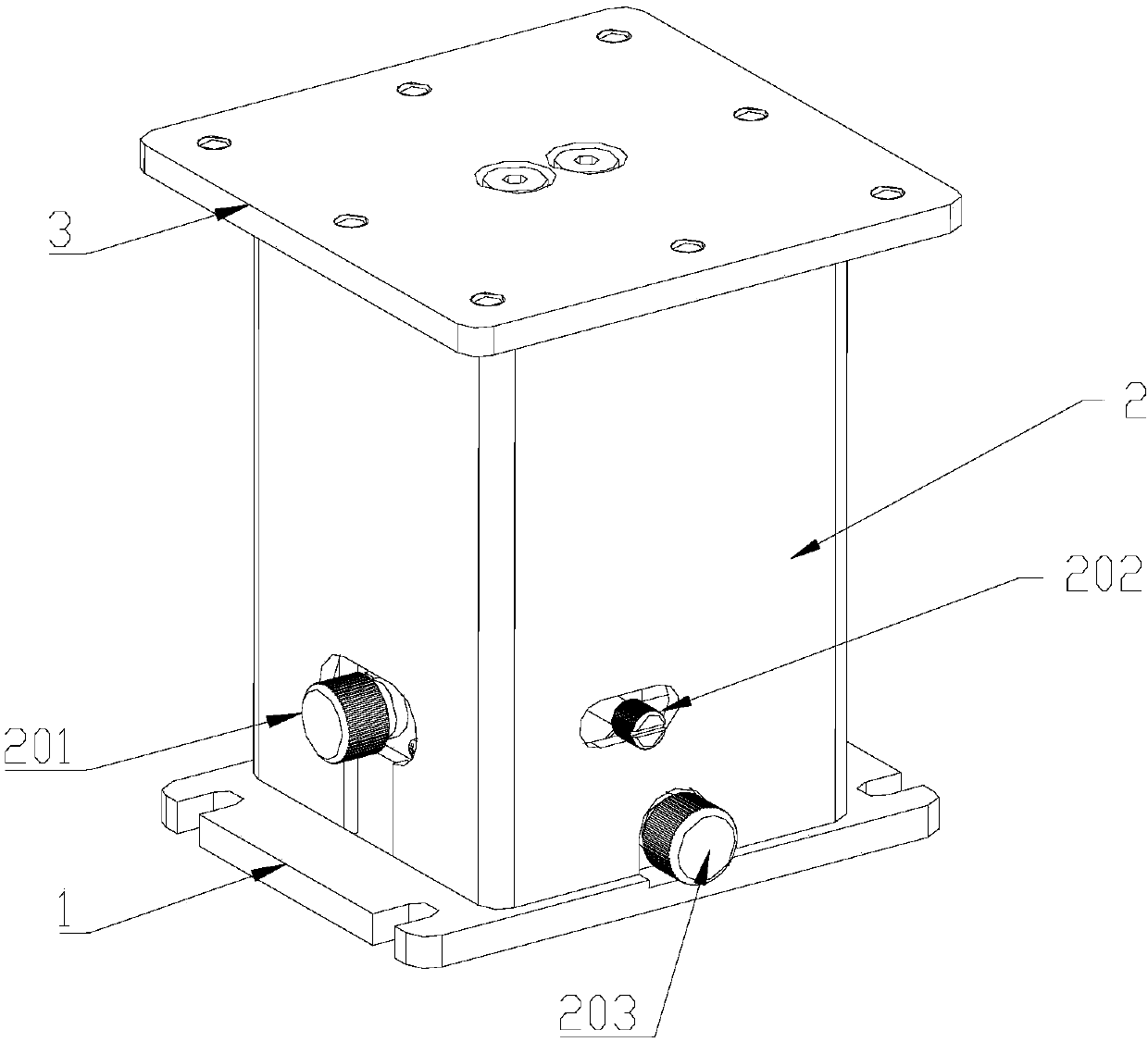

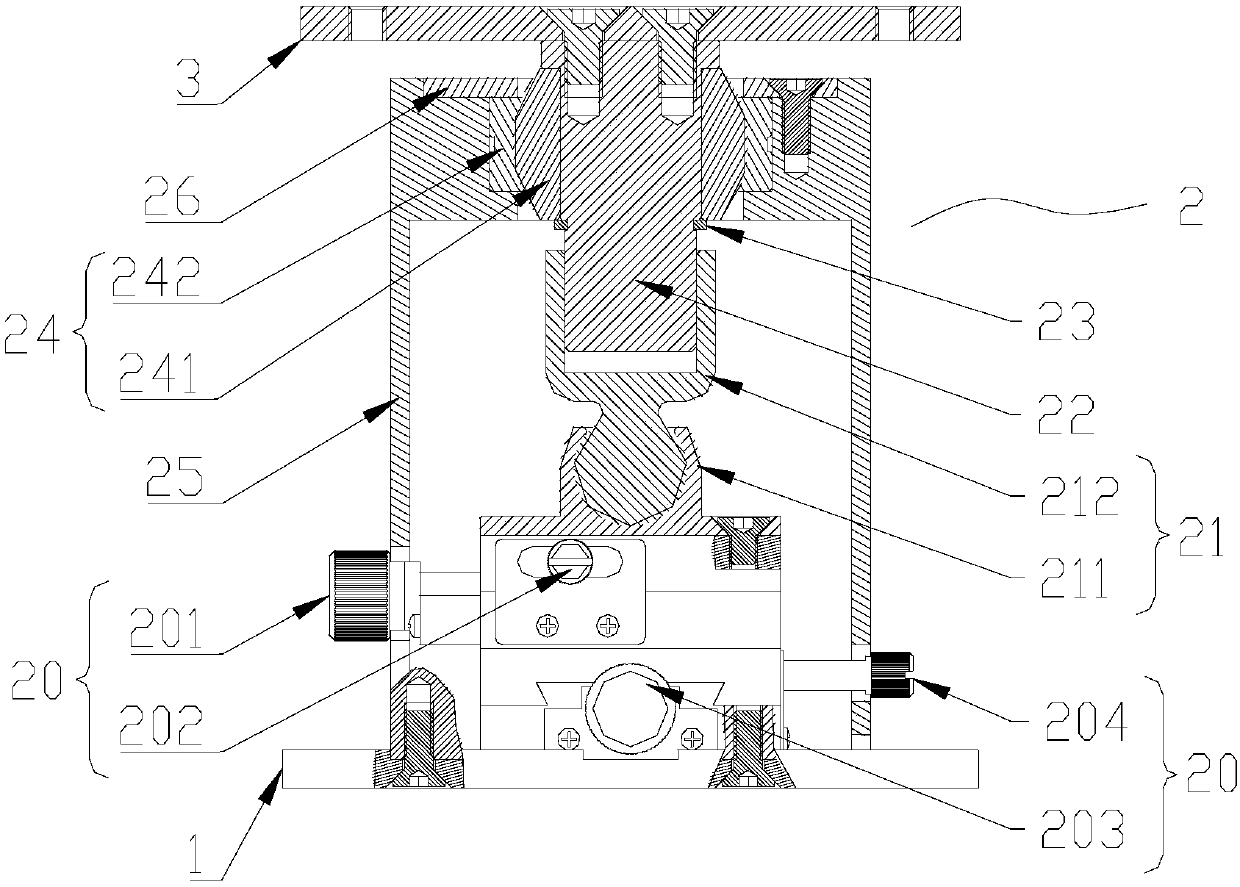

[0020] Such as Figure 1 to Figure 3 As shown, the horizontal universal adjustment device of this embodiment includes a base 1, an adjustment mechanism 2 and an object carrier 3. Among them, the adjustment mechanism 2 includes an XY moving table 20, a second joint bearing 21, a swing shaft 22, a circlip 23, a first joint bearing 24, a housing 25 and a bearing end cover 26.

[0021] The XY moving table 20 is locked and connected to the base 1 by a locking screw. The position of the XY moving table 20 is adjusted by screwing the X-direction adjusting screw 201 and Y-direction adjusting screw 203. In order to improve the adjustment accuracy, the X-direction adjusting screw 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com