Pre-embedded part experiment special template measuring and machining device and use method thereof

A technology for processing devices and embedded parts, applied in feeding devices, wood processing equipment, manufacturing tools, etc., can solve the problems of cutting size error, cutting line bending, and inability to measure template size in time, so as to achieve convenient measurement and processing. Strong operability and strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below by means of the accompanying drawings.

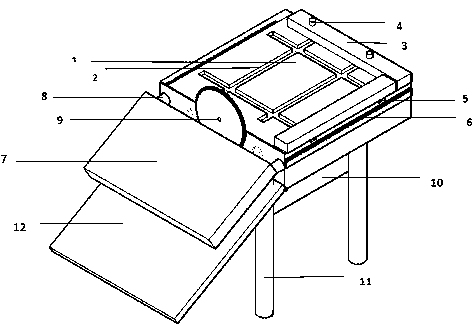

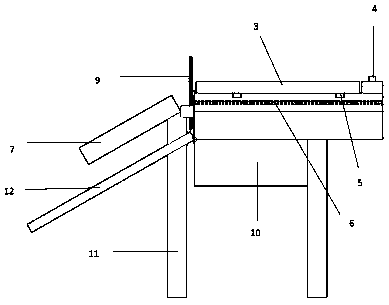

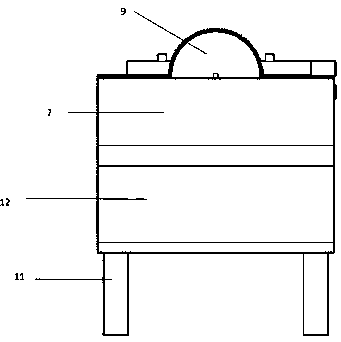

[0023] Such as figure 1 As shown, the present invention provides a measurement and processing device for a special template for embedded parts experiments, including a left workbench 7 and a right workbench 1, and the right workbench 1 is fixed on the cross section of the left workbench 7. The two shafts 8 are connected, and the circular saw 9 is fixed between the two shafts 8. The right side table 1 is provided with a chute 2, a right side baffle 3 and a front side baffle 5, and the chute 2 is set Between the front side fence 5, the right side fence 6 and the circular saw 9, it is in the shape of a well, and the front side fence 5 and the right side fence 3 can all move in the chute 2, and the right side The baffle plate 3 can be fixed on the right side workbench 7 by a fixing member.

[0024] The fixing part is a bolt 4, and the right side baffle 3 is provided with a hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com