Line body used for feeding of structural plates

A technology of structural boards and wire bodies, applied in the field of wire body materials for structural boards, can solve the problems of waste of manpower, heavy weight and lack of board materials, etc., and achieve the effect of liberating occupancy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

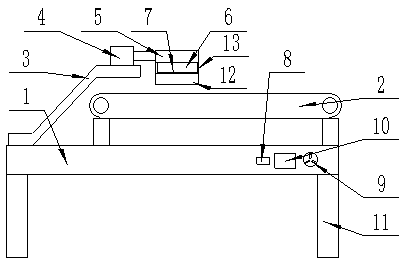

[0012] The present invention will be described in detail below with reference to the drawings, such as figure 1 As shown, a line body for structural sheet metal includes a workbench (1), a production line (2) is provided on the workbench (1), and a side surface of the workbench (1) is connected with an inclined Conveyor (3), one end of the inclined conveyor (3) is provided with a screening mechanism, and the screening mechanism consists of a rotating motor (4) arranged at one end of the inclined conveyor (3) and a rotating end of the rotating motor (4). The support ring (5), the raw material collection filter layer (6) fitted on the support ring (5) along the circumference, and the oscillator (7) arranged at the center of the outer and lower surface of the raw material collection filter layer (6), so The workbench (1) is provided with a controller (8), a mains interface (9) and a capacitive touch screen (10). The controller (8) is connected to the mains interface (9), the capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com