Trapezoidal straight corrugated plate production method

A production method and straight corrugated technology, applied in the field of trapezoidal straight corrugated plate production, can solve the problems of large amount of calculation and low efficiency, and achieve the effect of improving efficiency and reducing the total degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0155] The present invention will be further described in detail below in conjunction with the accompanying drawings.

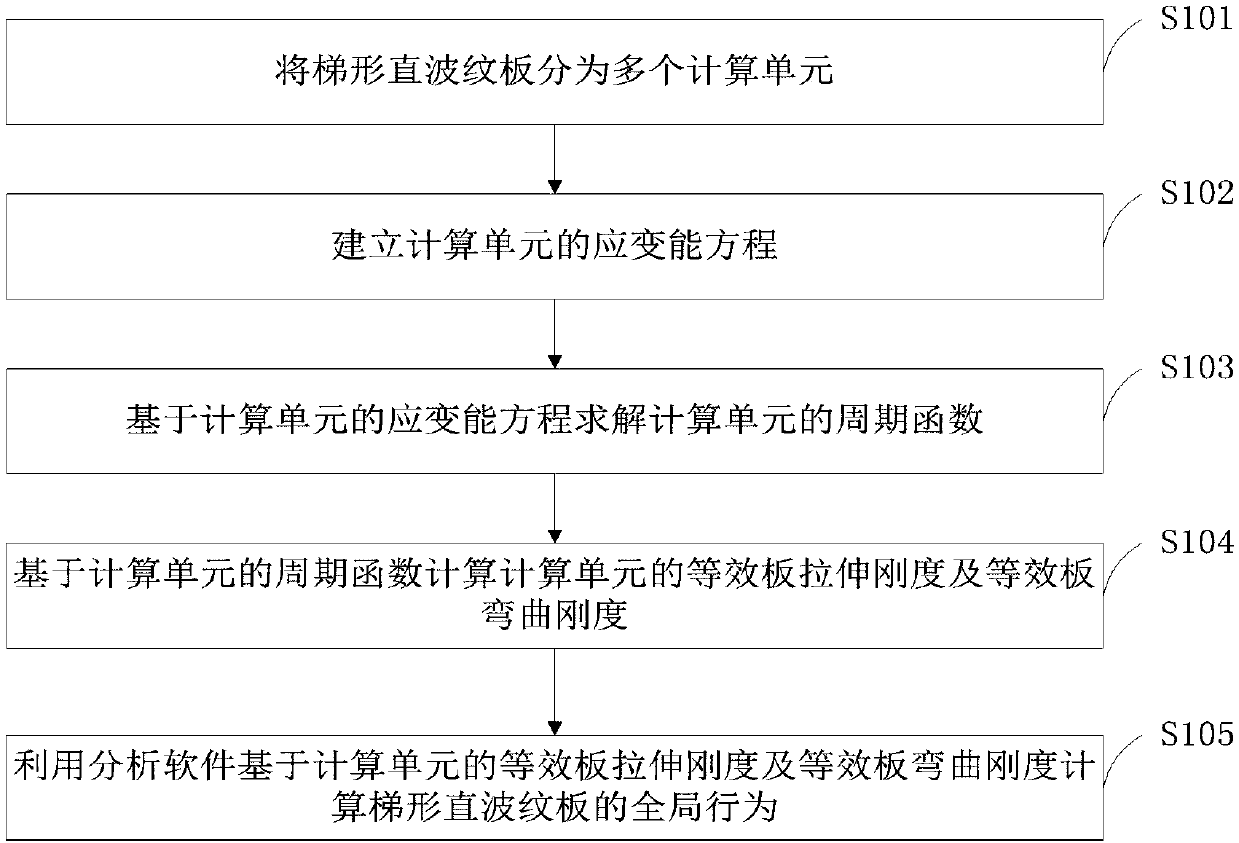

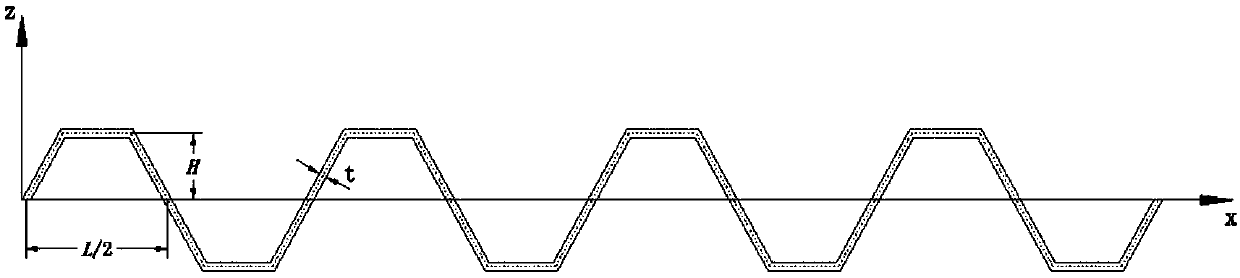

[0156] The invention discloses a production method of a trapezoidal straight corrugated plate, which includes designing a trapezoidal straight corrugated plate structure according to performance requirements, calculating the tensile stiffness and bending stiffness of the trapezoidal straight corrugated plate structure, and when the trapezoidal straight corrugated plate is stretched When the stiffness and tensile bending stiffness meet the performance requirements of the trapezoidal straight corrugated plate, manufacture the trapezoidal straight corrugated plate according to the designed trapezoidal straight corrugated plate structure, wherein the tensile stiffness, bending stiffness and The tension-bend coupling includes the following steps:

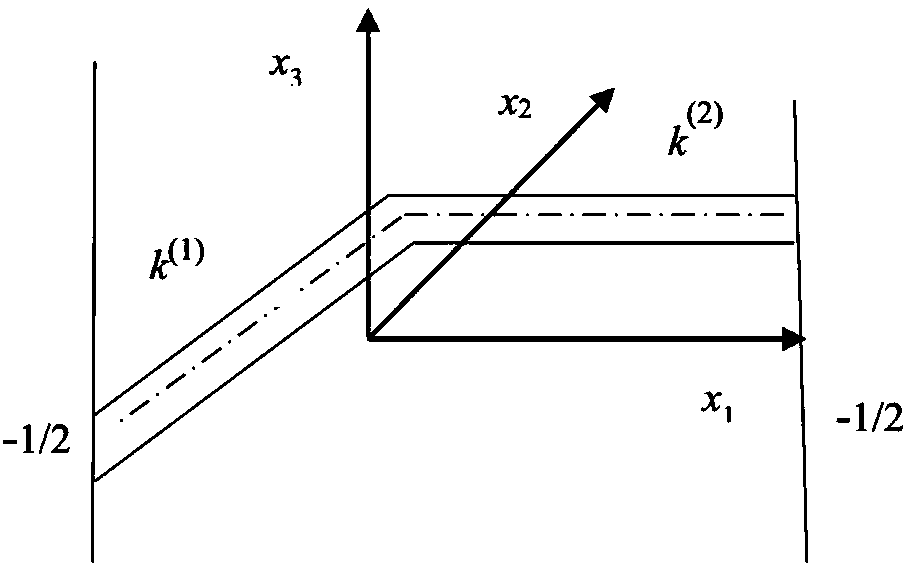

[0157] dividing the trapezoidal straight corrugated plate into a plurality of calculation units;

[0158] Establishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com