Cutting test bench for cutting head of heading machine

A technology of cutting test and cutting head, which is applied in the field of industrial and mining machinery and equipment testing, can solve the problems of high cost, difficult data collection, and difficult accurate identification of various parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

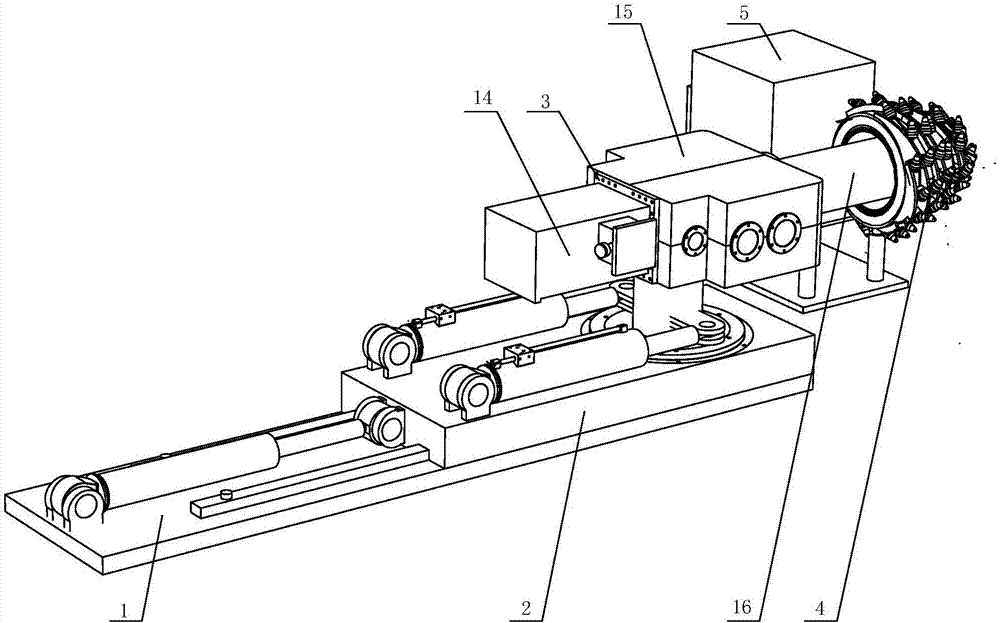

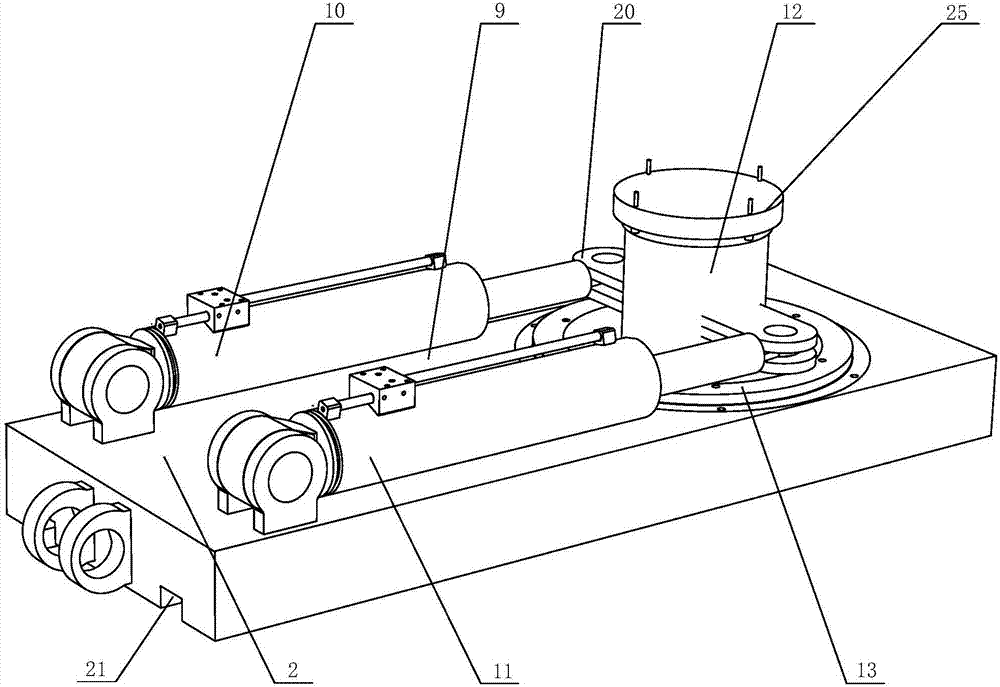

[0025] To solve existing problems such as Figure 1 to Figure 6 As shown, the present invention provides a cutting test bench for cutting head of roadheader, comprising sliding platform 1, rotary platform 2, cutting head driving device 3, cutting head 4 and simulated coal rock 5;

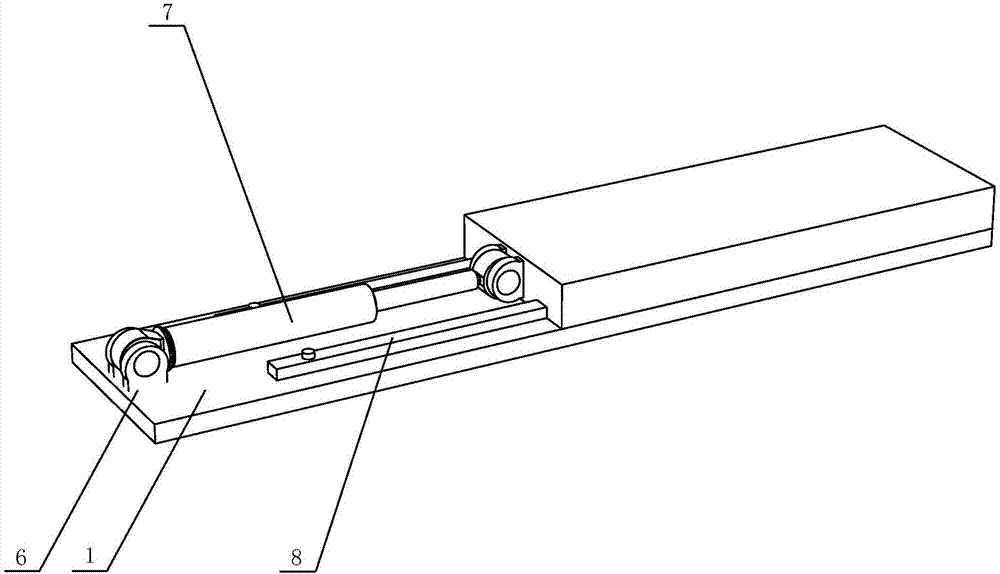

[0026] Sliding platform 1 comprises sliding platform bottom plate 6, a hydraulic cylinder, and this hydraulic cylinder is the first hydraulic cylinder 7, and guide rail 8, and first hydraulic cylinder 7 is arranged on the sliding platform bottom plate 6, and the upper surface of sliding platform bottom plate 6 is provided with connecting Ring, one end of the cylinder bottom of the first hydraulic cylinder 7 is connected to the connecting ring of the sliding platform bottom plate 6 through the connecting pin shaft, and the guide rail 8 is fixed on the sliding platform bottom plate 6 and placed parallel to the first hydraulic cylinder 7;

[0027] The main function of the sliding platform 1 is to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com