Spray nozzle arrangement

A spray nozzle, nozzle technology, applied in the direction of spray device, spray device, device to catch or kill insects, etc., can solve the problems of non-supply, high water and chemical consumption, uneven spray effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

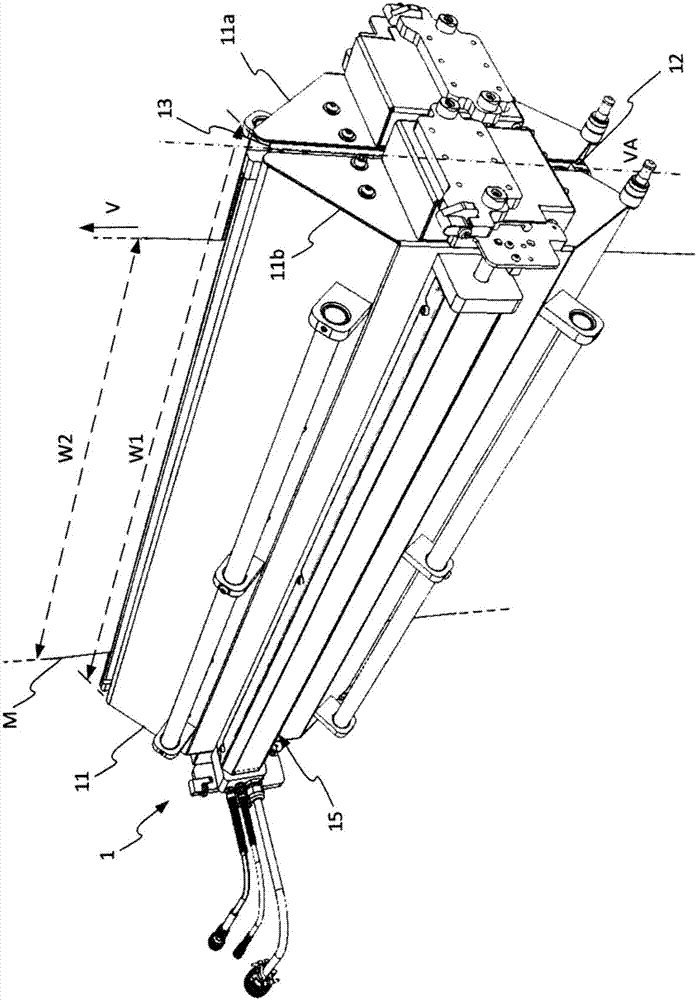

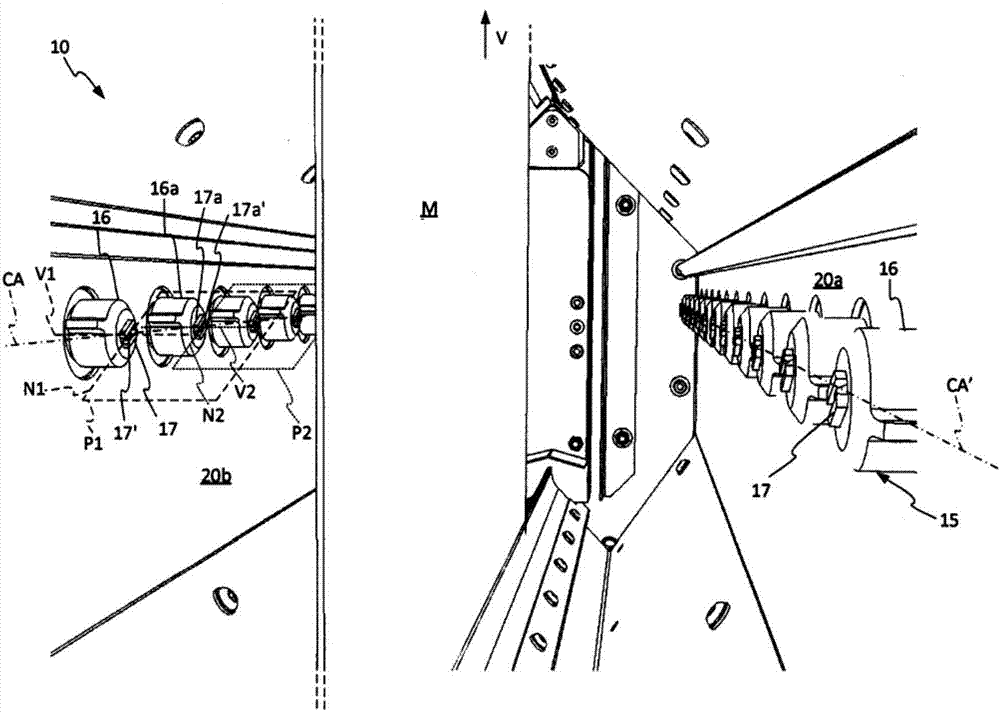

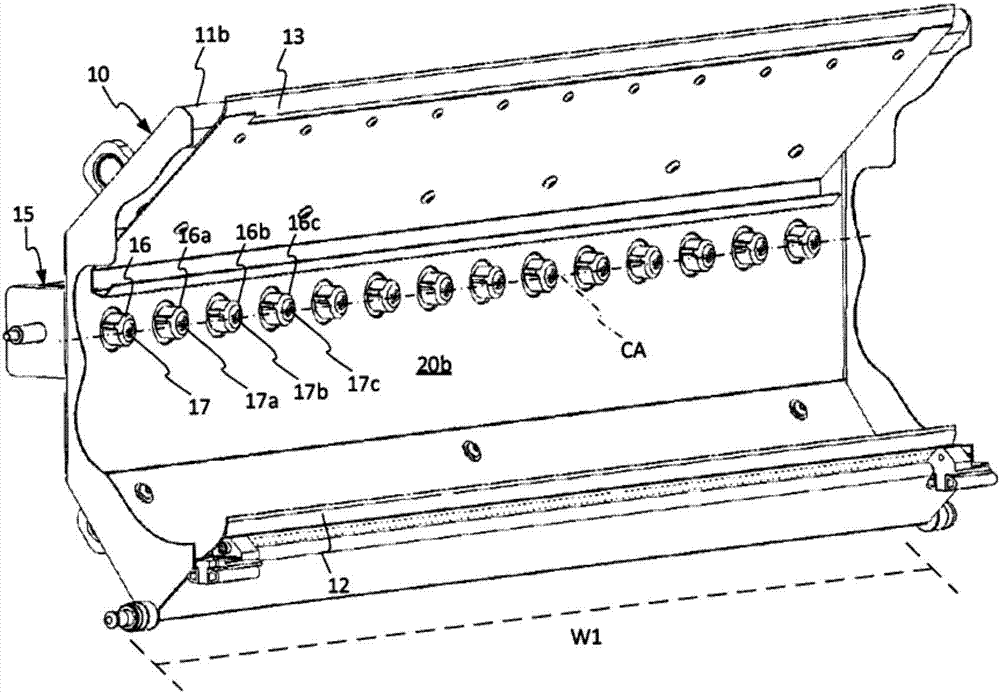

[0027] Referring to the drawings, there is presented an apparatus 10 for spraying fluid onto a piece of material M, such as a web or strip. The spray device 10 is preferably part of a spray unit of a fabric manufacturing process (not shown), with the web running through each component of the process. The manufacturing process in this embodiment involves a fabric material, but in other embodiments may involve other types of materials such as paper, wood, metal, plastic or other types. The material M (web or ribbon) runs through the spray device 10 in a substantially vertical direction V, but the direction in which the web runs may also be horizontal or any other preferred direction. The fluid to be sprayed can provide different properties to the material, such as dustproof, waterproof, fireproof, or make the material more flexible, or add a desired adhesive.

[0028] The spray device 10 comprises a chamber 11 through which the mesh M runs. The spray chamber 11 has an inlet 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com