A positioning riveting device for wing shaft seat assembly

A technology for positioning riveting and shaft seats, which is applied in the aerospace field, can solve the problems of poor accuracy of wing shaft seats, low positioning accuracy, and low pass rate, and achieve the effects of improving accuracy and rigidity, reducing labor intensity, and increasing pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

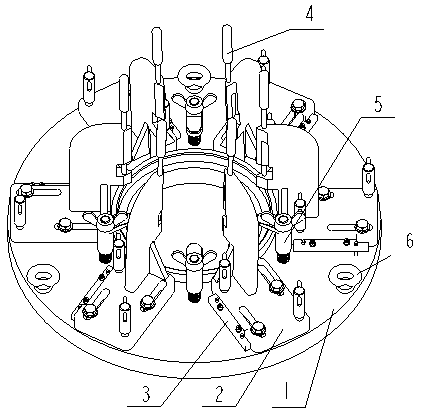

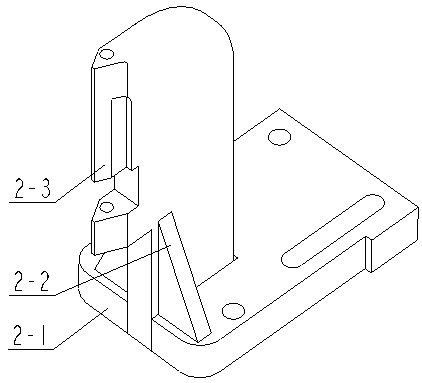

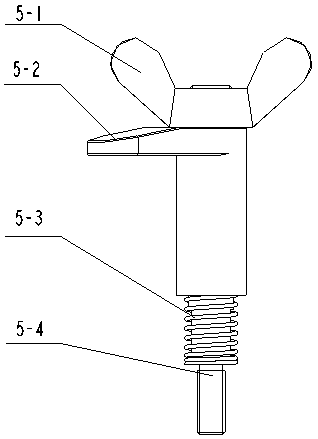

[0016] see figure 1 , a positioning riveting device for a vane shaft seat assembly, mainly comprising: a base 1, a positioning block 2, a limit block 3, a fixed shaft 4, a pressure plate assembly 5 and a lifting ring 6, wherein the base 1 adopts a ring structure , is the positioning base of the whole device. The center of the base 1 is designed with a circular step structure, which is the positioning reference of the shaft base parts in the fin shaft seat product; 1 to achieve fastening, and a plurality of them are evenly distributed along the axis of the base 1. There are six positioning blocks 2 in this embodiment. The position is fixed to ensure the accuracy of the distance between the upper shaft seat and the lower shaft seat; the limit block 3 is also positioned and fastened on the base 1 through cylindrical pins and screws, and the limit block 3 is set on the left side of the positioning block 2 and carried out in the same direction as it. The angle is evenly distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com