Connection joint of H-shaped steel beam and round-section steel-reinforced concrete column and construction method

A technology of concrete columns and connecting nodes, applied in the direction of buildings, building structures, etc., can solve problems such as node connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

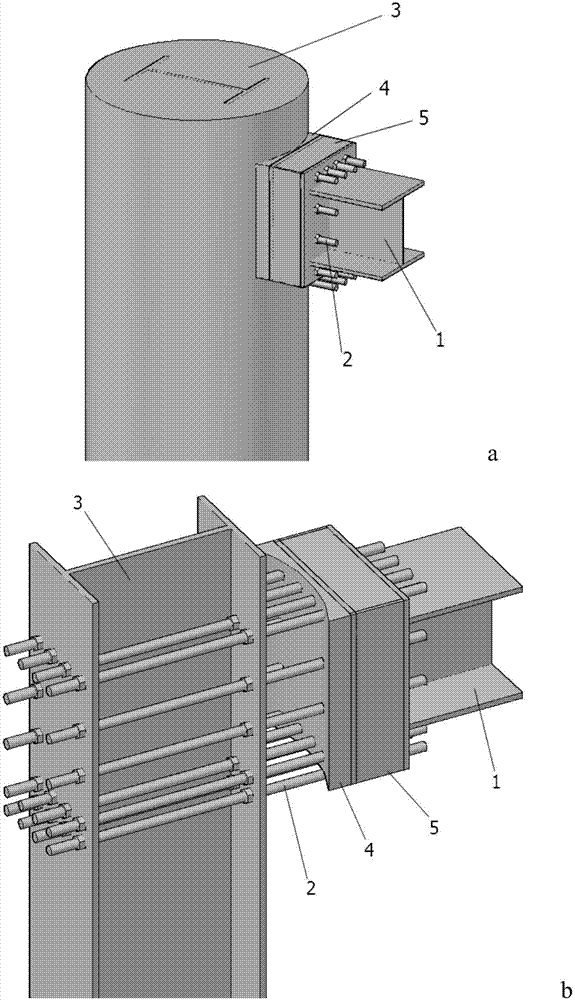

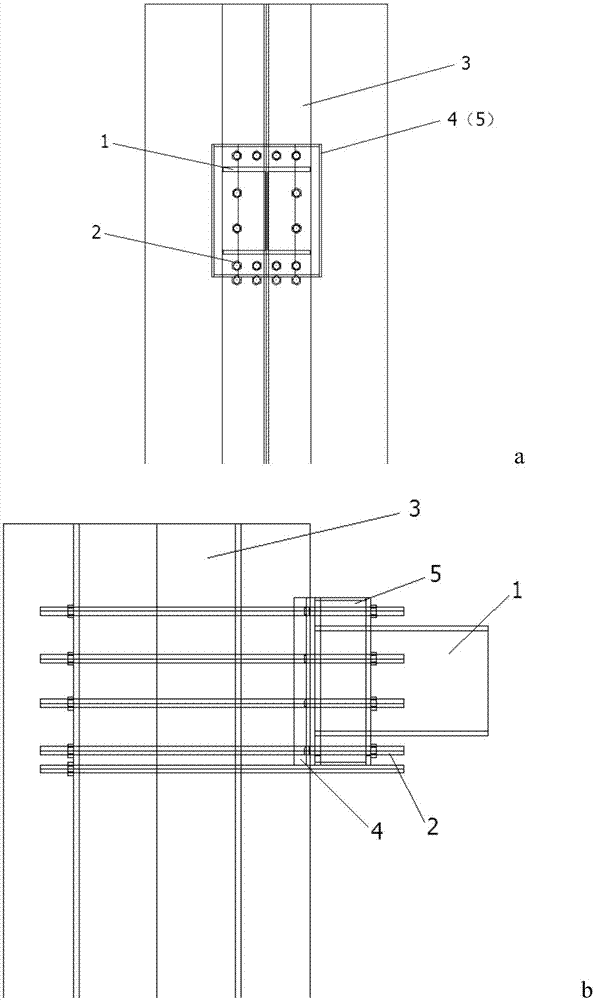

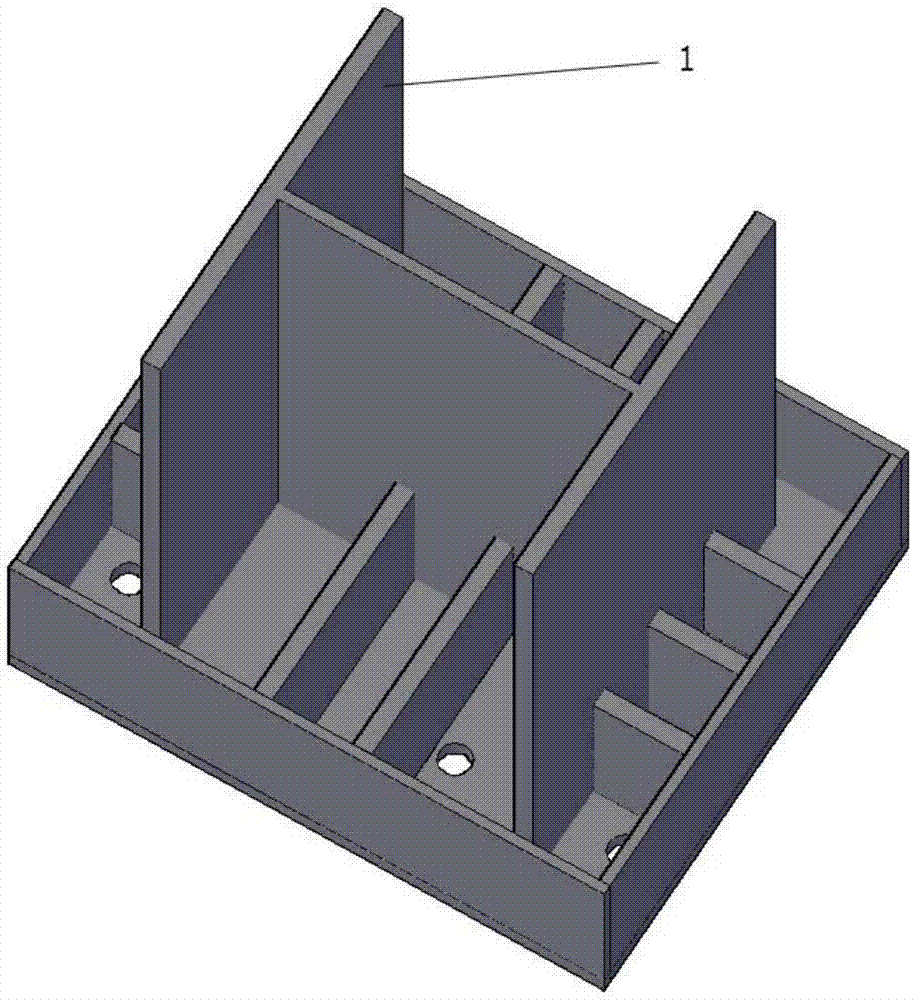

[0017] Such as Figure 1-4 As shown, a connection node and method of a H-shaped steel beam and a circular section steel concrete column, the construction method is as follows:

[0018] In the first step, when the concrete structure is constructed to a certain height, the steel keel is pre-embedded in the concrete column that needs to be connected with the H-shaped steel beam. At the same time, the steel keel should be kept on the upper and lower 1-2 floors continuously to ensure sufficient shear resistance strength.

[0019] The second step is to pre-embed high-strength bolt rods in the holes drilled on the steel keel, and fix them with nuts on the rear side of the upper an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap