Connecting joint for H-shaped steel beam and steel reinforced concrete beam and manufacturing method

A technology of concrete beams and connecting nodes, which is applied in the direction of architecture and building construction, and can solve problems such as node connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

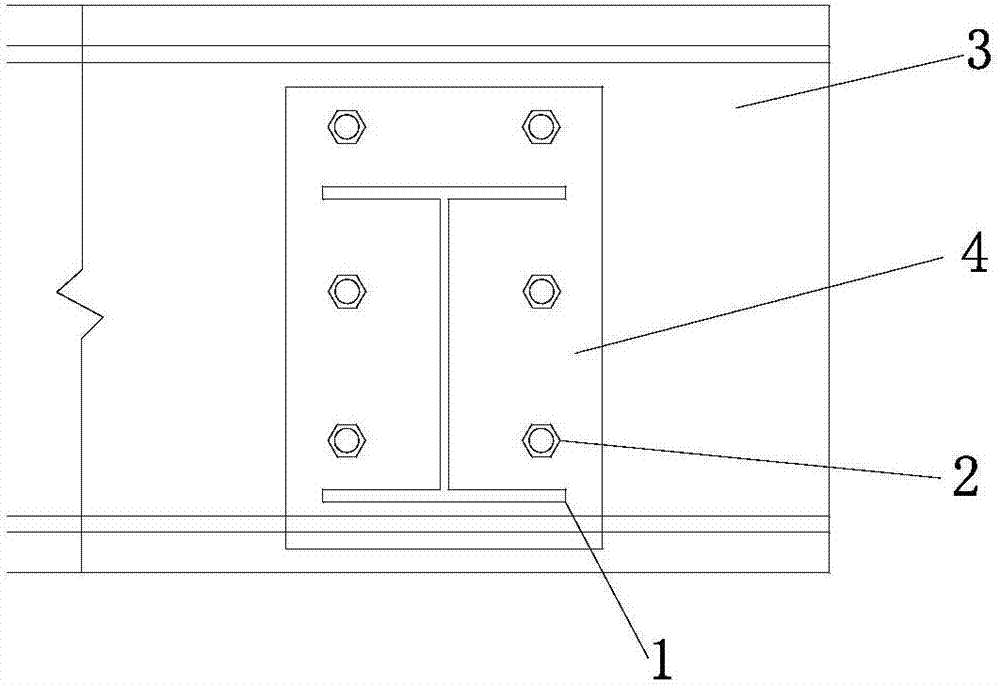

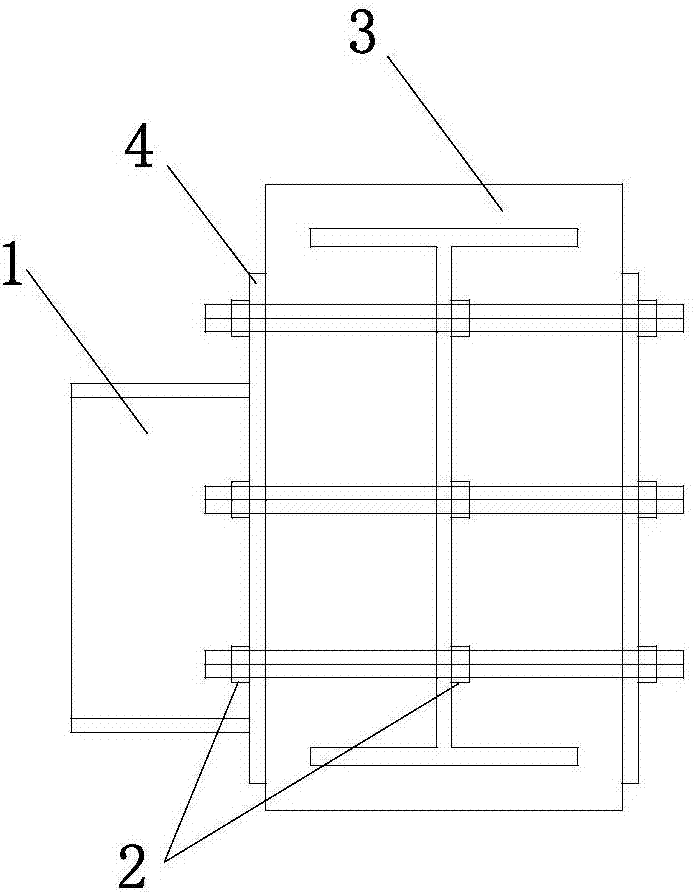

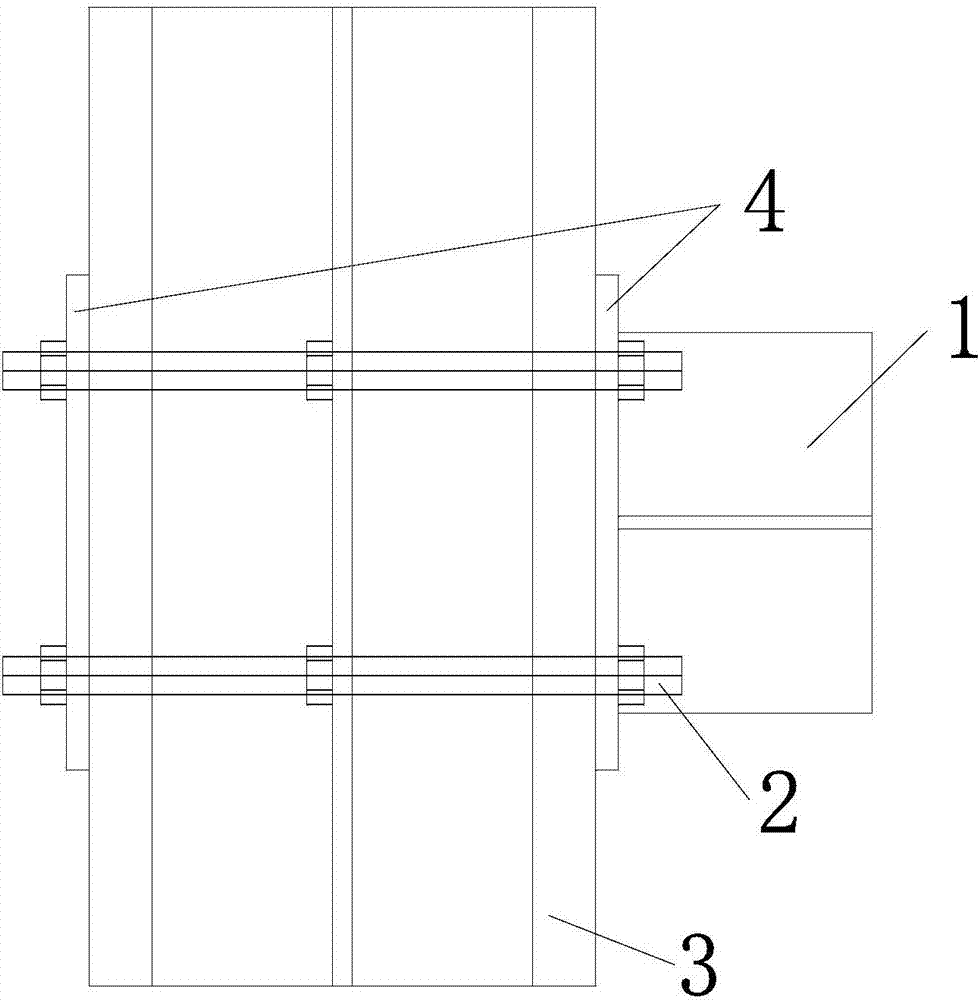

[0015] Such as Figure 1-4 Shown, a connection node and method of H-shaped steel beam and steel concrete beam, its construction method is as follows:

[0016] In the first step, when the concrete structure is constructed to a certain height, the steel concrete is pre-embedded in the concrete beams that need to be connected with the H-shaped steel beams.

[0017] The second step is to pre-embed the high-strength bolt rods in the holes drilled on the steel keel, and fix them with nuts on the inner side of the web of the steel keel to prevent the high-strength bolt rods from slipping or even being pulled out in the concrete when they are stressed. out.

[0018] The third step...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap