Garbage can

A technology for trash cans and barrel walls, applied in the field of trash cans, which can solve problems such as false collisions, living space restrictions, and fixed volumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

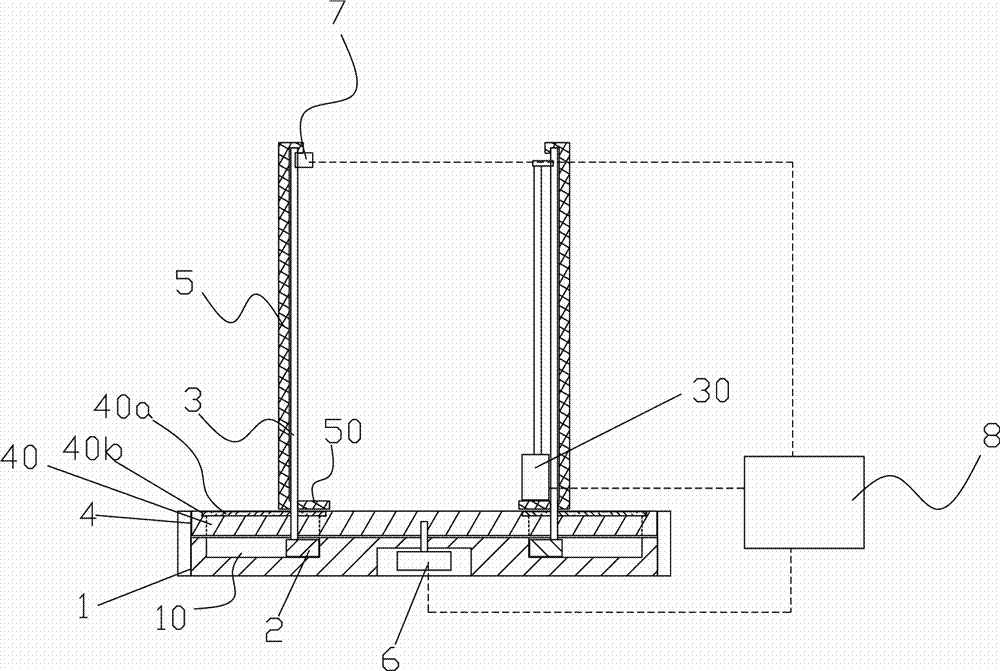

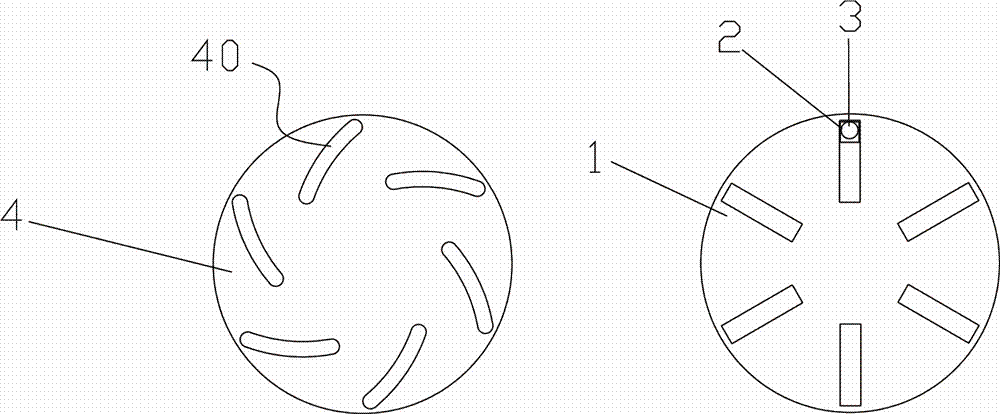

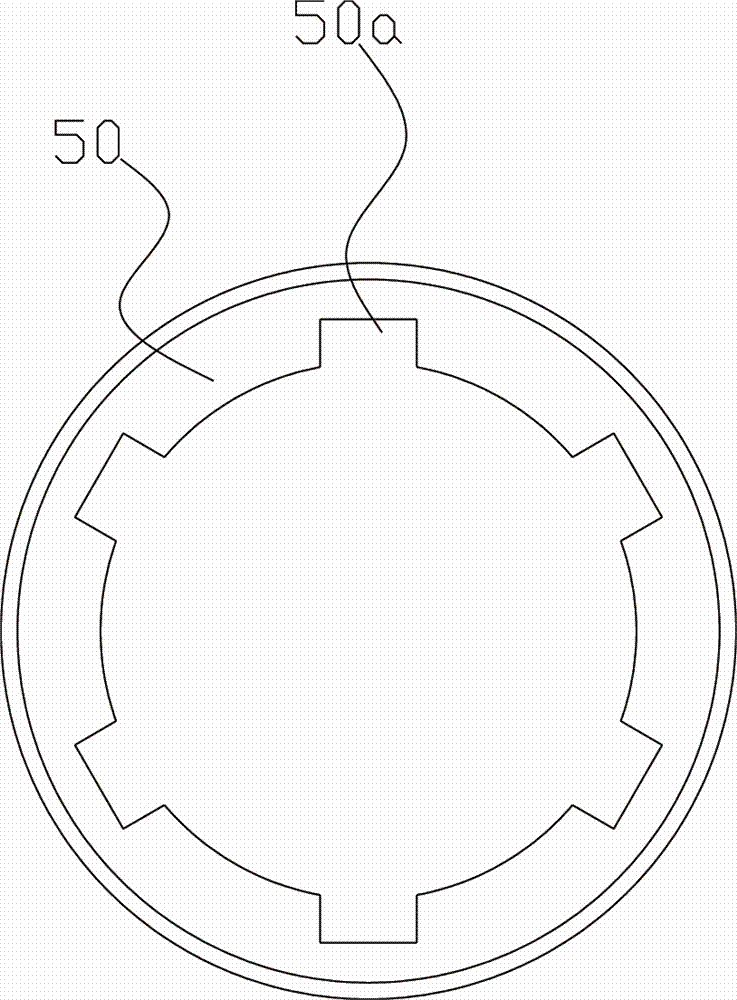

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 3 , a trash can, comprising a base 1, linear chutes 10 are evenly spaced along the circumference of the base 1, a slider 2 is slidably arranged in the chute 10, and a slider 2 is installed on the slider 2 The upper end is provided with a support rod 3, and a turntable 4 is rotated above the base 1, and strip-shaped holes 40 corresponding in quantity and position to the chute 10 are evenly spaced along the circumference of the turntable 4. The upper side of the strip-shaped hole 40 is provided with a ring of mounting flanges 40b, and a flexible covering sheet 40a is provided on the mounting flange 40b, and the support rod 3 passes through the strip-shaped holes 40 and the covering sheet 40a , also includes the elastic barrel wall 5 stretched between each of the support rods 3, the base 1 is provided with a self-locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com