Device for cutting beefsteaks

A technology of steak and cutting mechanism, applied in slaughtering, meat processing equipment, food science, etc., can solve the problems of difficult to achieve fast cutting, waste of time and energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

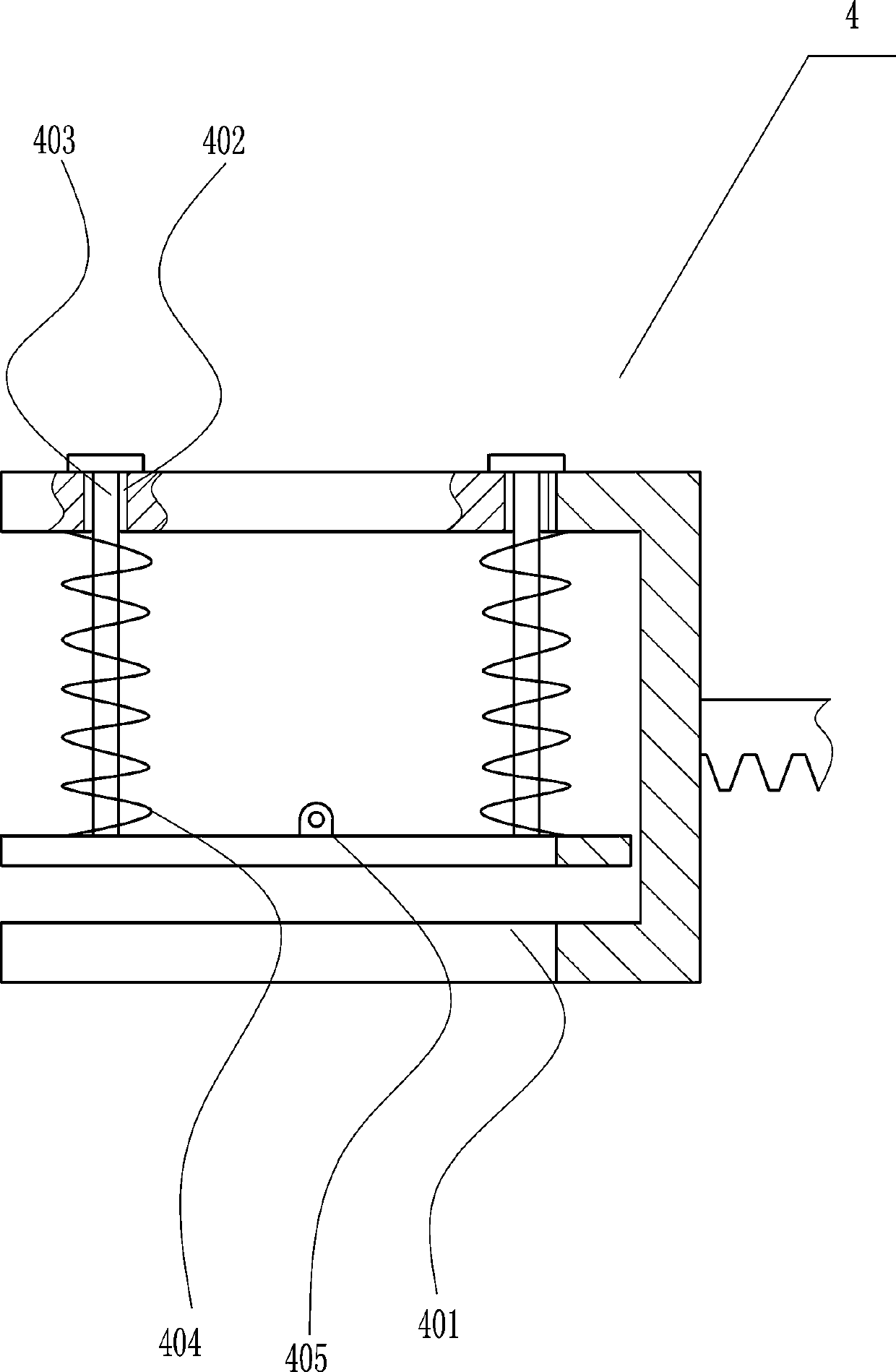

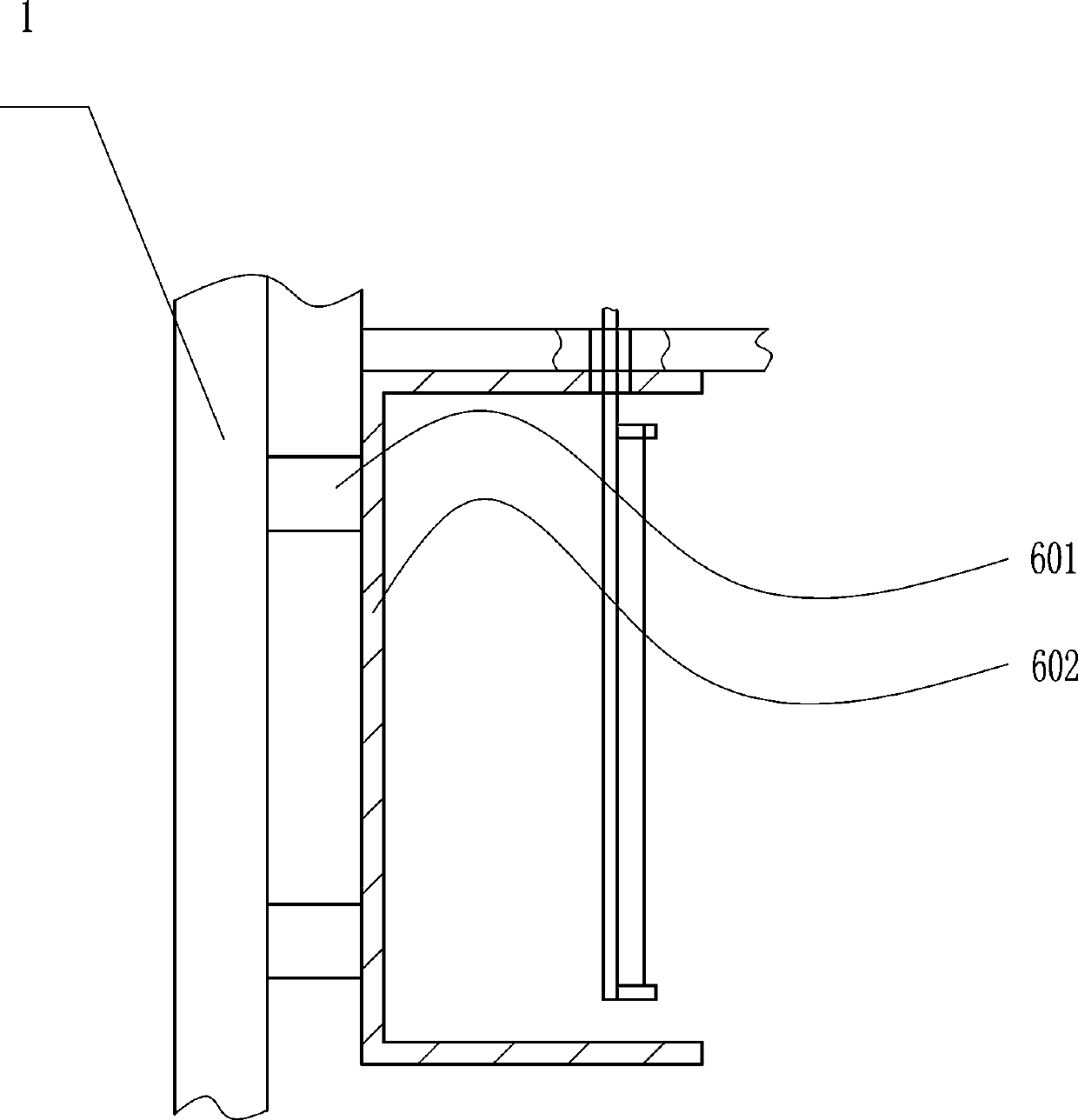

[0032] A device for cutting steaks such as Figure 1-7 As shown, it includes a frame 1, a cutting mechanism 2, a left and right moving mechanism 3 and a clamping mechanism 4, the cutting mechanism 2 is arranged on the upper right side of the frame 1, and the left and right moving mechanism 3 is arranged on the upper right of the frame 1, and the clamping The fetching mechanism 4 is arranged below the cutting mechanism 2 , and the clamping mechanism 4 is connected to the left end of the left-right moving mechanism 3 .

Embodiment 2

[0034] A device for cutting steaks such as Figure 1-7 As shown, it includes a frame 1, a cutting mechanism 2, a left and right moving mechanism 3 and a clamping mechanism 4, the cutting mechanism 2 is arranged on the upper right side of the frame 1, and the left and right moving mechanism 3 is arranged on the upper right of the frame 1, and the clamping The fetching mechanism 4 is arranged below the cutting mechanism 2 , and the clamping mechanism 4 is connected to the left end of the left-right moving mechanism 3 .

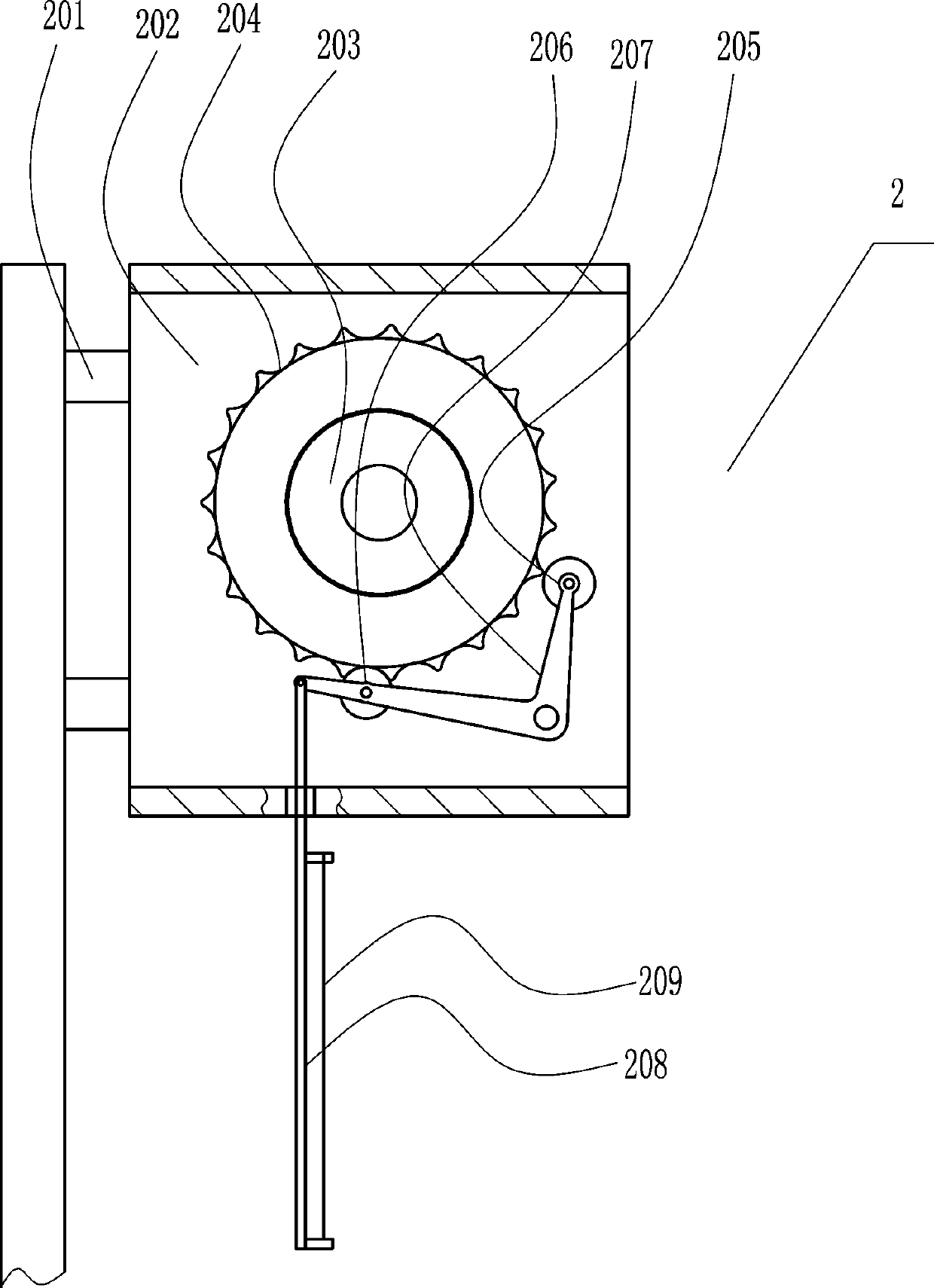

[0035] Cutting mechanism 2 comprises first support 201, cabinet 202, motor 203, cam 204, first roller 205, second roller 206, first rocking bar 207, slide bar 208 and saw blade 209, the top right of frame 1 Two first brackets 201 are arranged symmetrically on the side. The right end of the first bracket 201 is provided with a chassis 202. The chassis 202 is provided with a motor 203. The output shaft of the motor 203 is fixed with a cam 204. The right side of th...

Embodiment 3

[0037] A device for cutting steaks such as Figure 1-7 As shown, it includes a frame 1, a cutting mechanism 2, a left and right moving mechanism 3 and a clamping mechanism 4, the cutting mechanism 2 is arranged on the upper right side of the frame 1, and the left and right moving mechanism 3 is arranged on the upper right of the frame 1, and the clamping The fetching mechanism 4 is arranged below the cutting mechanism 2 , and the clamping mechanism 4 is connected to the left end of the left-right moving mechanism 3 .

[0038]Cutting mechanism 2 comprises first support 201, cabinet 202, motor 203, cam 204, first roller 205, second roller 206, first rocking bar 207, slide bar 208 and saw blade 209, the top right of frame 1 Two first brackets 201 are arranged symmetrically on the side. The right end of the first bracket 201 is provided with a chassis 202. The chassis 202 is provided with a motor 203. The output shaft of the motor 203 is fixed with a cam 204. The right side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com