Electric drill depth control structure

A technology of depth control and electric drilling, which is applied in the direction of manufacturing tools, drilling/drilling equipment, boring machines/drilling machine components, etc., which can solve problems such as troublesome operation and difficult control of the drilling depth of electric drill bits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

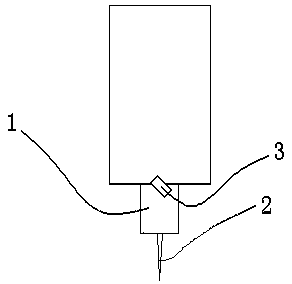

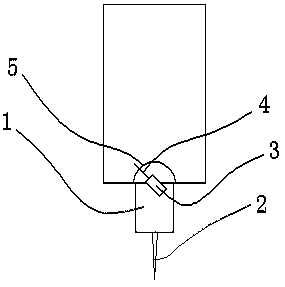

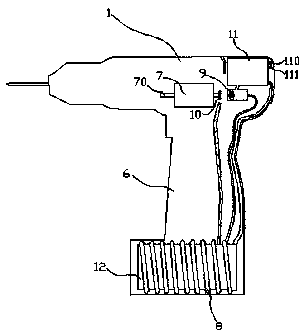

[0013] The specific embodiment is described in further detail to the present invention: see figure 1 , Embodiment 1, an electric drill depth control structure, including an electric drill body 1, an electric drill bit 2 is arranged on the electric drill body 1, a light source 3 capable of emitting a concentrated beam is arranged on the electric drill body 1, and the light source 3 emits The concentrated light beam of the electric drill bit 2 is at a certain angle. In this embodiment, the concentrated light beam emitted by the light source 3 is at 45 degrees to the electric drill bit 2. Because tan45°=1, the length of the electric drill and the concentrated light beam The moving distance of the point on the wall, the electric drill bit 2 is a copper alloy, which is made of 70% copper, 20% manganese, and 10% silicon mixed and fired. Embodiment 1 When in use, the electric drill bit 2 vertically drills into the plane, and the drilling depth of the electric drill is controlled acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com