Cutting board double edges straight line milling device

A cutting board and straight line technology, which is applied in the field of cutting board bilateral linear milling equipment, can solve the problems of inconsistency in the finished product size and poor flatness of the side of the cutting board, and achieve the effects of ensuring accuracy, improving efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

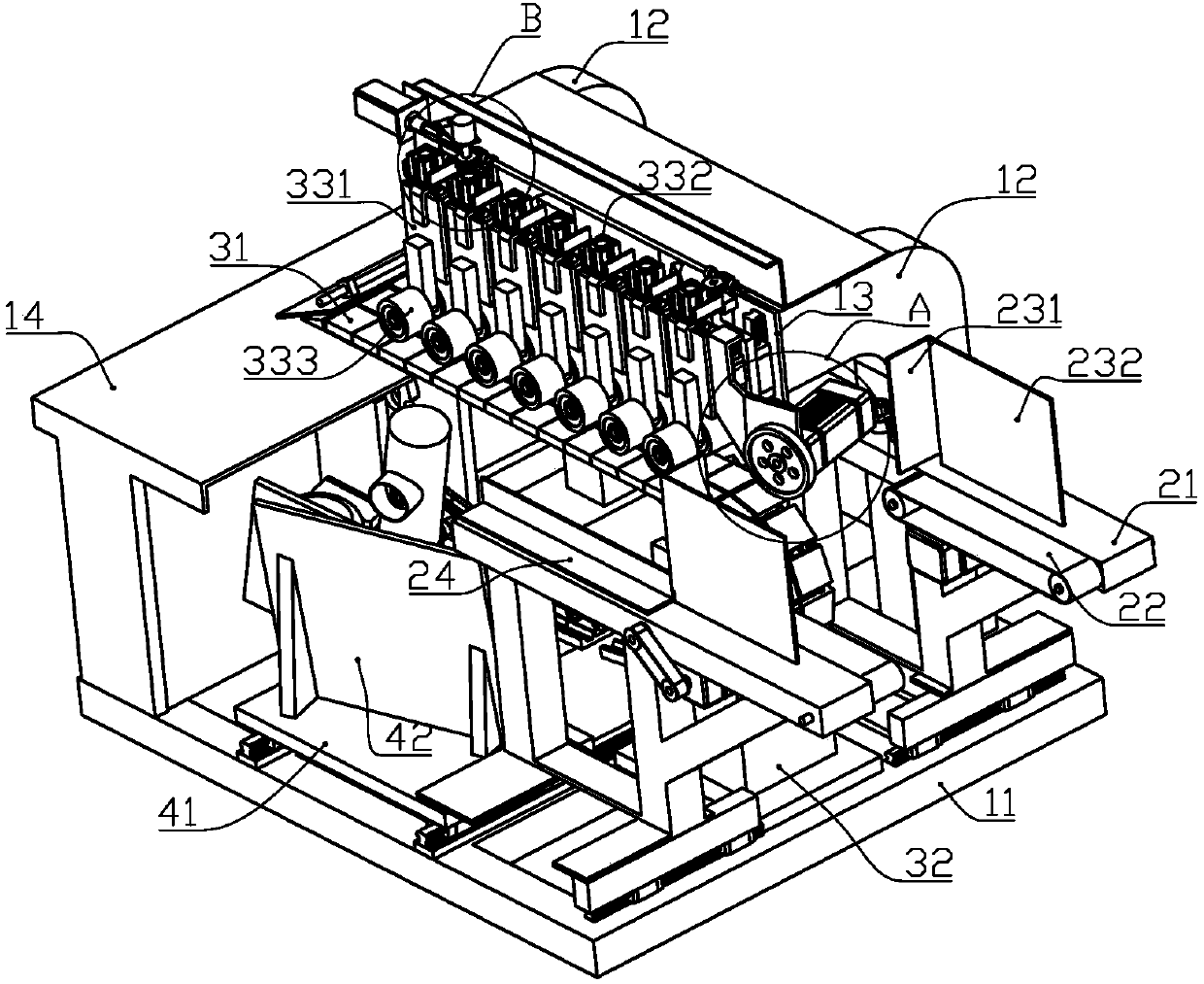

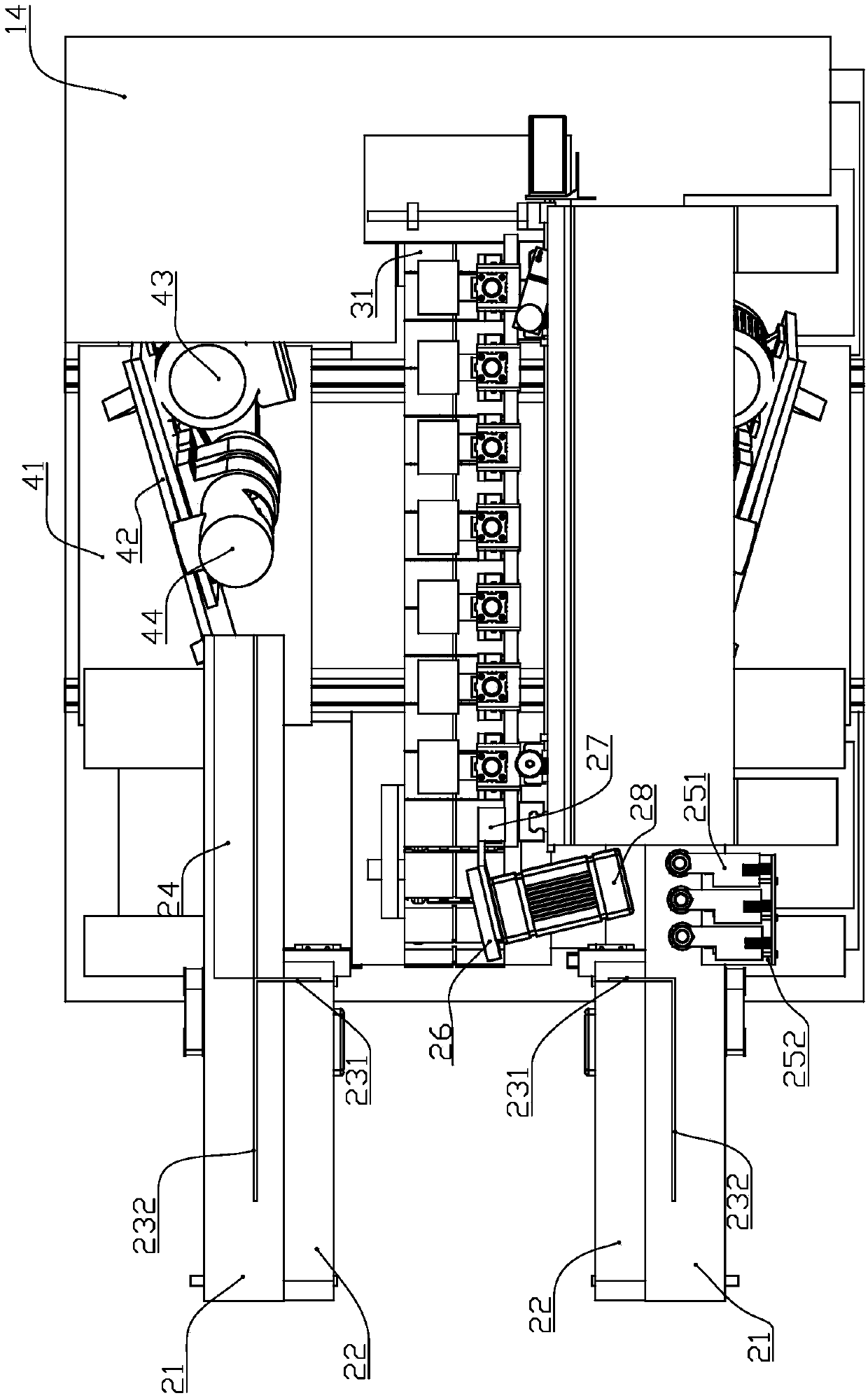

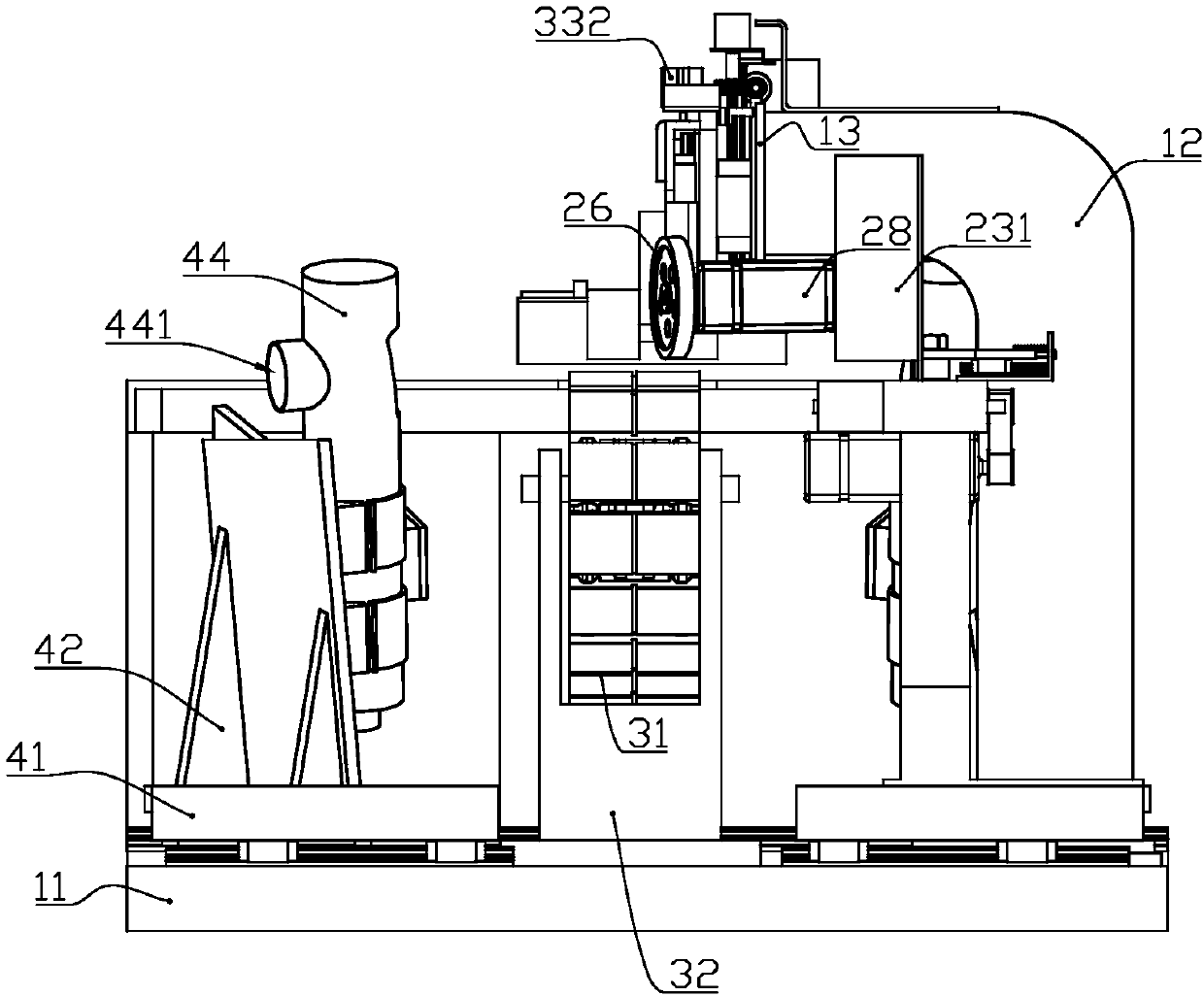

[0042] The technical solution of the present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

[0043] refer to Figure 1-7 , the cutting board double-sided linear milling equipment according to the present invention is slightly longer in the vertical direction and shorter in the horizontal direction as a whole. The cutting board double-sided linear milling equipment includes a base 11, with the cutting board transmission direction as the front, and the middle position of the base 11 is longitudinally provided with a transmission system. The left and right sides of the system are respectively equipped with edge milling devices symmetrically, the rear end of the transmission system is provided with a feeding system, and the front of the transmission system is also provided with a discharge platform 14 .

[0044] The feeding system includes a positioning unit, two brackets 21 symmetrically arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com