Connecting structure and method for prefabricated columns and prefabricated beams of fabricated building frame structure

A technology of frame structure and connection structure, which is applied in the direction of building structure and construction, can solve the problems of inconvenient production, high stiffness of node area, complicated structure, etc., and achieve the effect of improving construction efficiency, reasonable disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

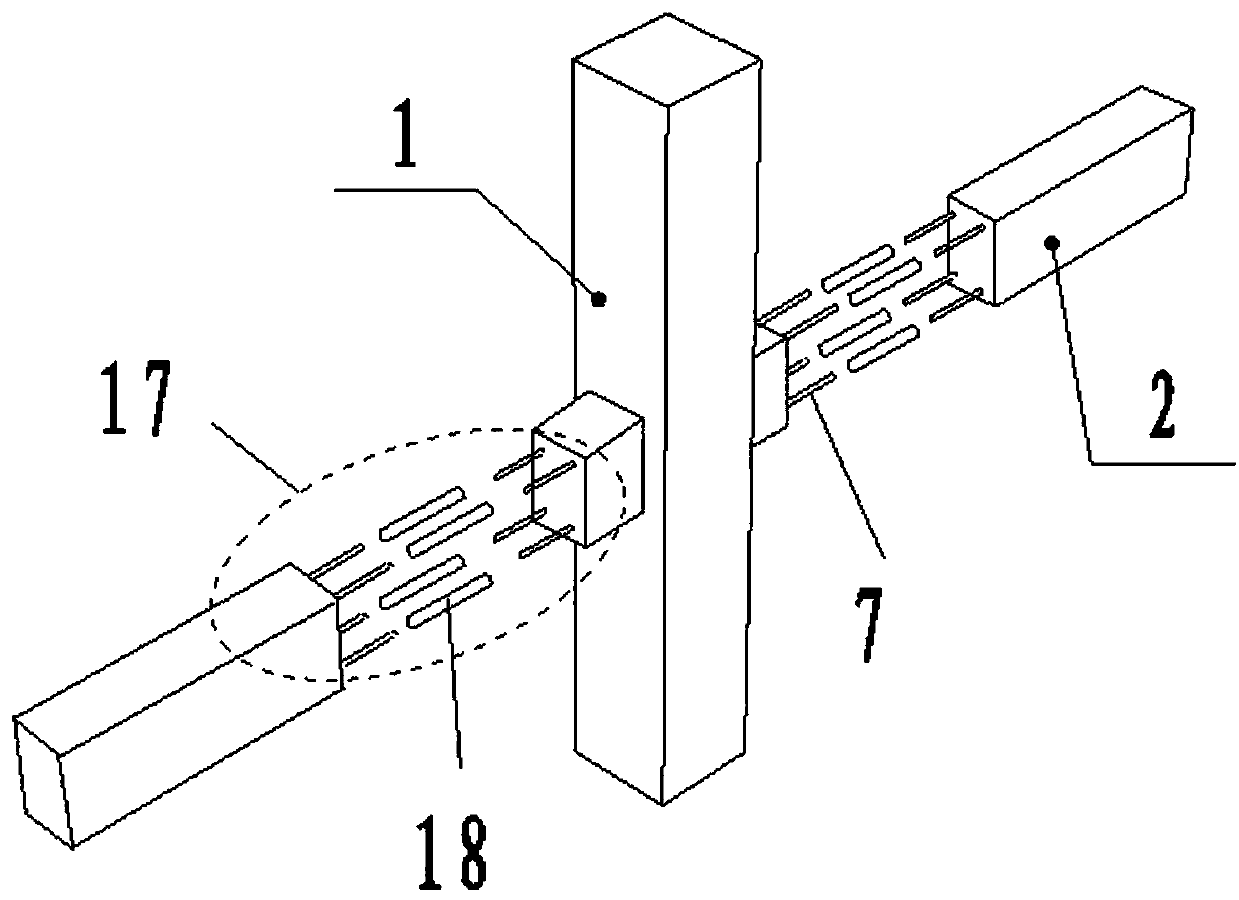

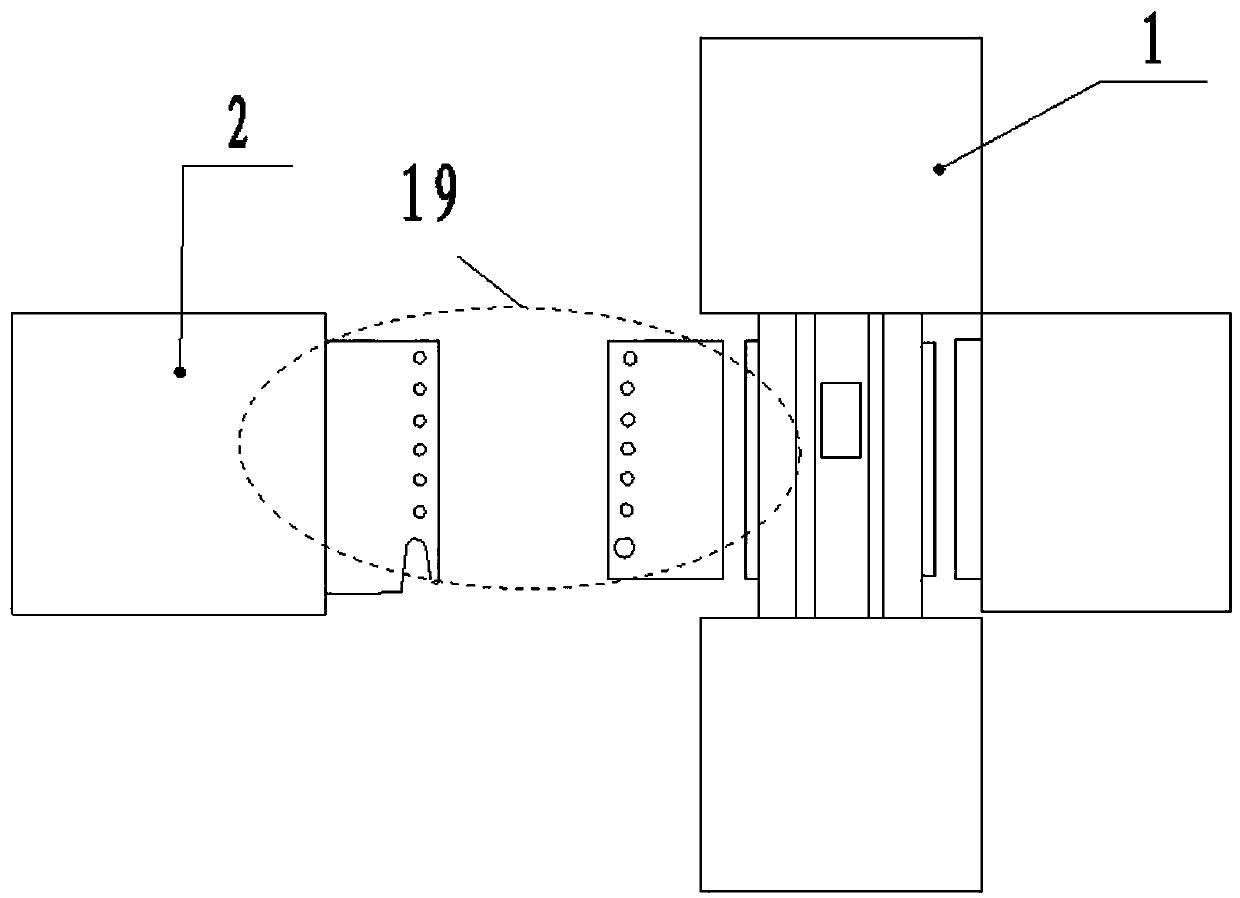

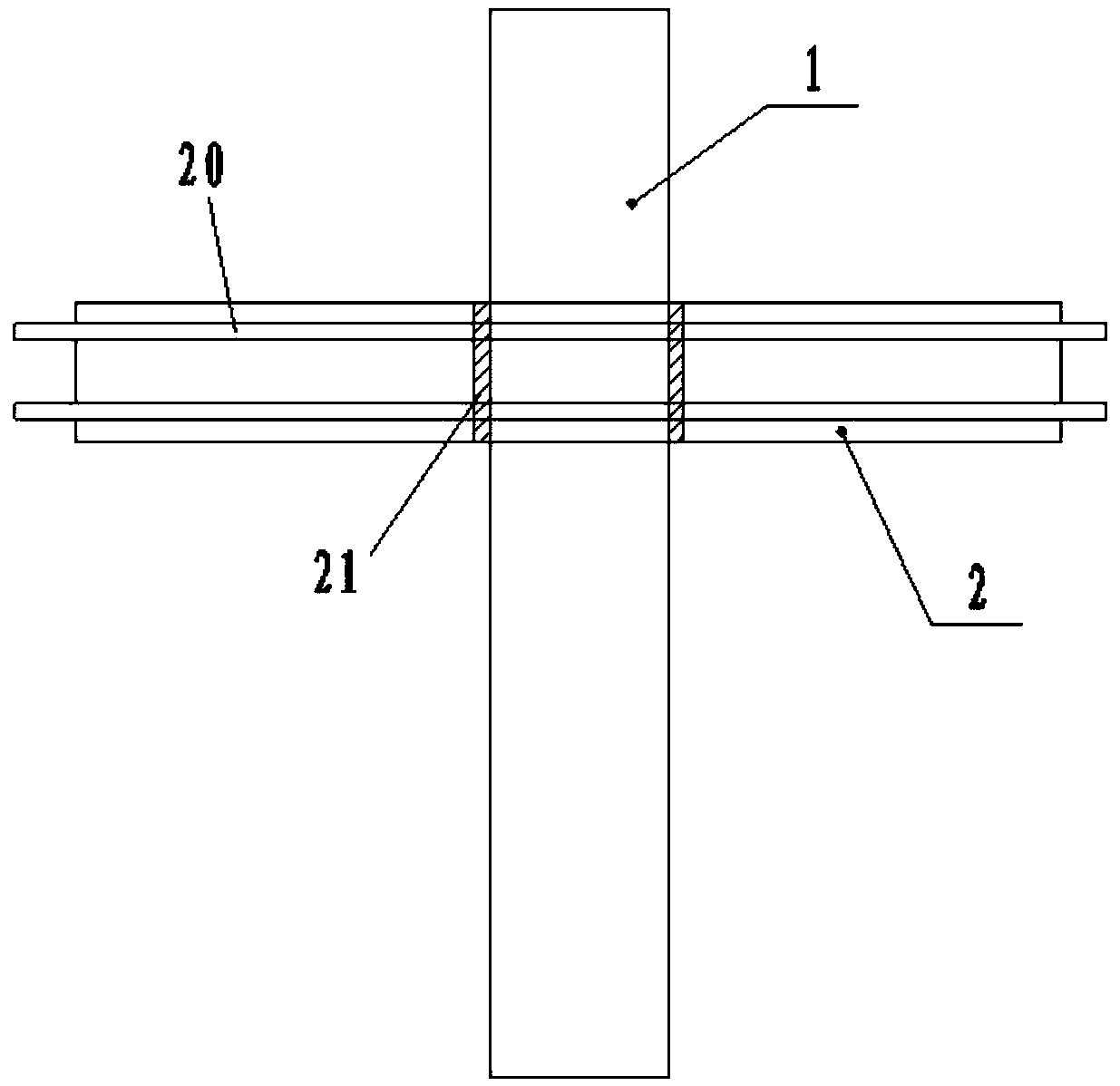

[0076] Such as Figure 4-22 As shown, the prefabricated column and prefabricated beam connection structure of a prefabricated building frame structure of the present invention includes a prefabricated column 1 and a prefabricated beam 2, the prefabricated column 1 and the prefabricated beam 2 are formed by pouring reinforced concrete, and the prefabricated column 1 is surrounded by a There is at least one concealed corbel section 3, and the prefabricated column 1 and the concealed corbel section 3 are integrally poured, such as Figure 6-8 Shown, on the prefabricated column 1, it is the prefabricated central column that surrounds four pieces of hidden corbel sections 3, which are arranged on the frame (such as Figure 10 In the middle of the shown), the prefabricated side columns surrounded by three hidden corbel sections 3 on the prefabricated column 1 are set on the frame (such as Figure 10 As shown), the prefabricated corner columns surrounded by two hidden corbel section...

Embodiment 2

[0086] Such as Figure 4-22As shown, the present invention is a prefabricated column and prefabricated beam connection structure of a prefabricated building frame structure. The prefabricated column 1 is pre-embedded with prefabricated column reinforcing ribs 22, and at least one end of the prefabricated column 1 is provided with a prefabricated column. The column steel plate 23, the prefabricated column steel plate 23 is connected with the prefabricated column reinforcing rib 22, and the ring surface of the prefabricated column steel plate 23 is evenly provided with connecting through holes 24, and the prefabricated column 1 corresponding to the connecting through hole 24 is preset with The installation groove 25 is connected by bolts. When two prefabricated columns 1 need to be connected, after the prefabricated column steel plates 23 at the ends of the two prefabricated columns 1 are butted, the bolts 26 are installed in the connecting through holes 24 to realize the connect...

Embodiment 3

[0088] Such as Figure 4-22 Shown, the present invention a kind of prefabricated column and prefabricated beam connection method of prefabricated building frame structure, it comprises steps:

[0089] In the prefabricated component factory, the prefabricated component consisting of the prefabricated column 1 and the concealed corbel section 3 is poured as a whole, and the prefabricated column 1 and the concealed corbel section 3 are integrally poured;

[0090] Pouring the prefabricated beam 2; the prefabricated beam 2 is connected to the prefabricated beam lap joint 5 of the hidden corbel section 3 on the two prefabricated columns 1 through the corbel section lap joints 8 at both ends, and the corbel section lap joints 8 are lapped with the prefabricated beam After the joint 5 is lapped, connect the corbel connection steel plate 9 on the corbel section lap joint 8 with the prefabricated beam connection steel plate 6 on the prefabricated beam lap joint 5 .

[0091] The pouring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com