Lining test device

A testing device and bushing technology, which can be used in measurement devices, vehicle testing, and mechanical component testing, etc., can solve problems such as failure to truly reflect bushing wear conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

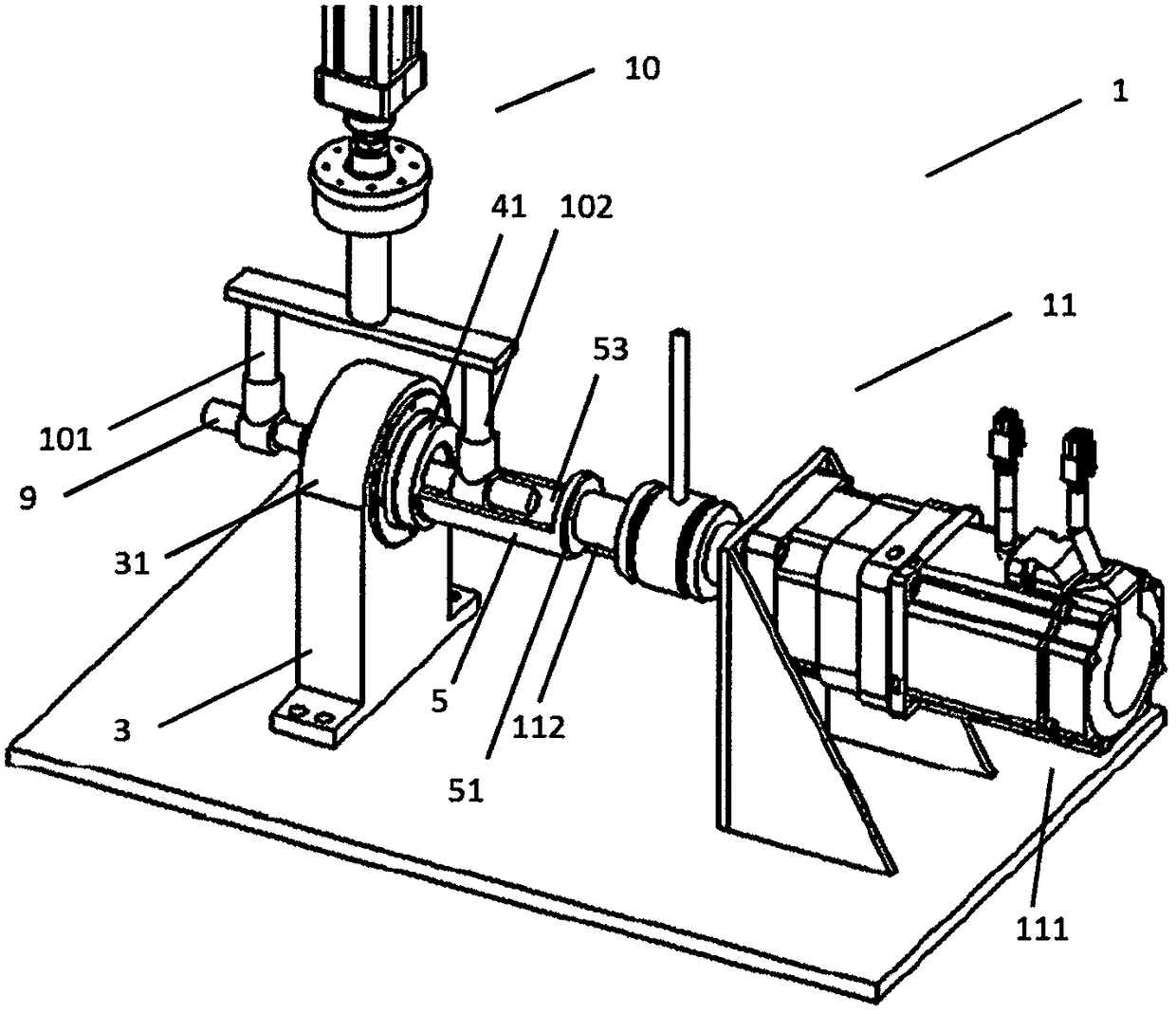

[0025] Such as figure 1 with 2 As shown, a bushing testing device 1 includes:

[0026] Base 3 with a mounting ring 31 on the top of the base;

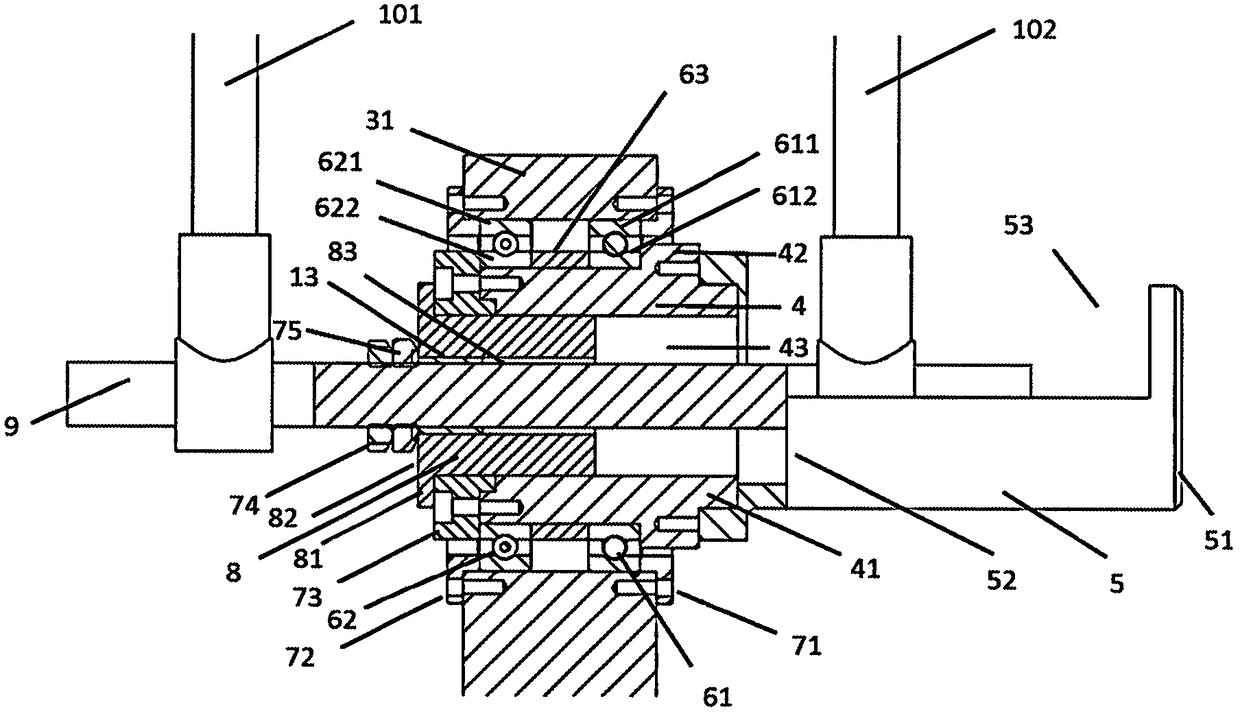

[0027] Hole seat 4, the hole seat 4 is arranged in the cavity of the mounting ring 31, one end of which extends out of the cavity of the mounting ring 31 to form a rotating drive end 41, and the outer surface of the hole seat 4 close to the rotating drive end 41 also includes a second A limit flange structure 42;

[0028] Two rolling bearings 61 and 62 respectively include an outer ring 611, an inner ring 612, an outer ring 621, and an inner ring 622. The rolling bearings 61 and 62 are installed between the mounting ring 31 and the hole seat 4, and the outer ring 611 and 621 is in contact with the inner wall of the mounting ring 31, the inner rings 612 and 622 are in contact with the outer wall of the socket 4, and one side of the inner ring 612 is in contact with the side of the first limiting flange structure 42; A spacer ring 63...

Embodiment 2

[0050] Such as Figure 4 As shown, a bushing testing device includes:

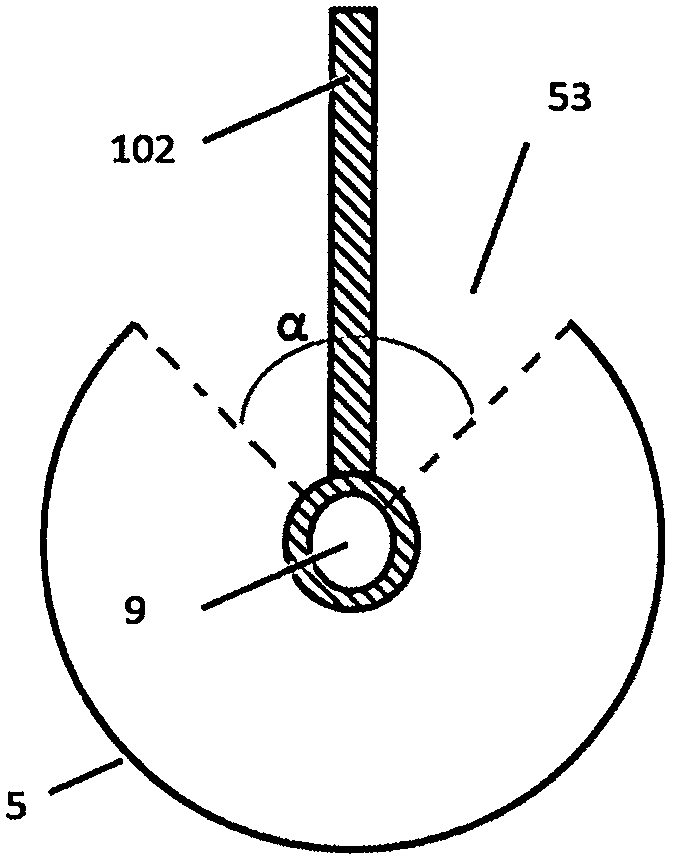

[0051] A rotary driving device, the rotary driving device includes a motor 121 and a rotating shaft 122 . Wherein, the rotating shaft 122 is a Z-shaped shaft, one end of the rotating shaft 122 is connected to the motor 121 , and the other end is connected to the rotating driving end 41 of the socket 4 . The axis of rotation of a transverse axis 1221 of the rotating shaft 122 coincides with the axis of the fixed shaft 9 .

[0052] Other settings of the bushing testing device are the same as in Embodiment 1.

[0053] When the bush testing device is in operation, the rotary drive device 11 drives the rotary shaft 122 to reciprocate at a certain angle. The rotating shaft 122 will drive the hole seat 4, the bush positioning seat 8 and the bush to be tested 13 installed in the space 83 for accommodating the bush to be tested to rotate in the rolling bearing. At the same time, the pressure loading device appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com