Air valve and air valve seat ring abrasion tester

A valve seat ring and wear test technology, which is applied in the direction of testing wear resistance and testing material strength by applying repetitive force/pulsation force, which can solve the problem that the fretting wear of valve and valve seat ring cannot be controlled, and the amount of wear cannot be accurately controlled, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

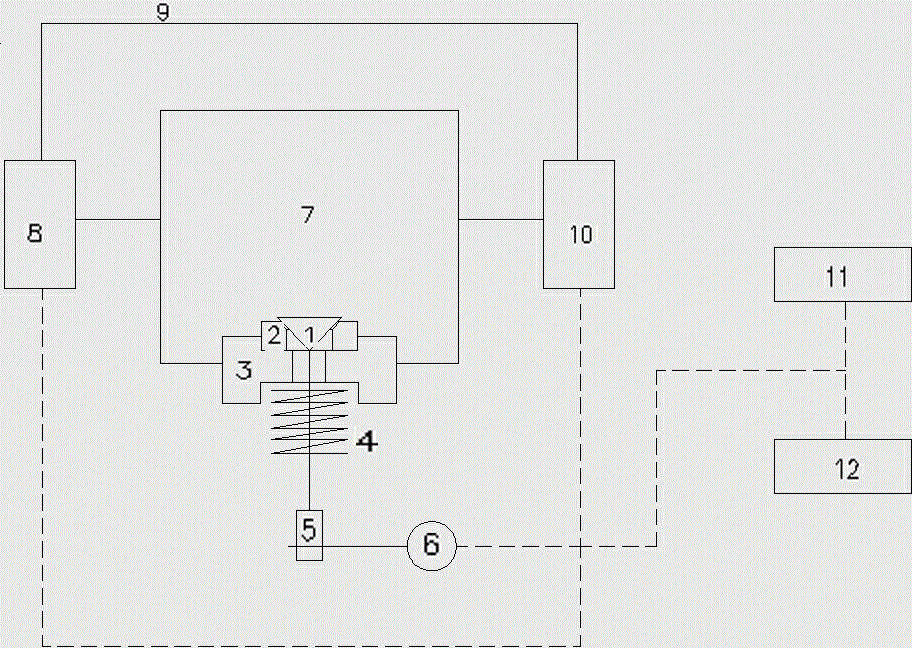

[0007] Such as figure 1 As shown, a valve and valve seat wear testing machine includes a test platform, a driving mechanism, a high temperature and high pressure airflow generating mechanism, a control mechanism, and a monitoring mechanism. The test platform is connected to the high temperature and high pressure airflow generating mechanism. The driving mechanism is connected to the test platform, the control mechanism is connected to the driving mechanism and the high temperature and high pressure air flow generating mechanism, and the monitoring mechanism is connected to the test platform, the driving mechanism and the high temperature and high pressure air flow generating mechanism. The test platform consists of valve 1, valve seat 2, valve seat mounting plate 3, spring 4, and test chamber 7. The V-shaped cone of valve 1 is inserted in the center hole of valve seat 2, and valve seat 2 Connected with the valve seat ring mounting plate 3 about the center hole coaxially, the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com