Locomotive grounding structure

A technology for vehicles and locomotives, applied in the field of grounding devices for electrified railways and urban rail transit locomotives, can solve problems such as rolling bearing electric corrosion, grounding failure, poor contact, etc., to avoid partial wear and rigid damage, prolong service life, and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

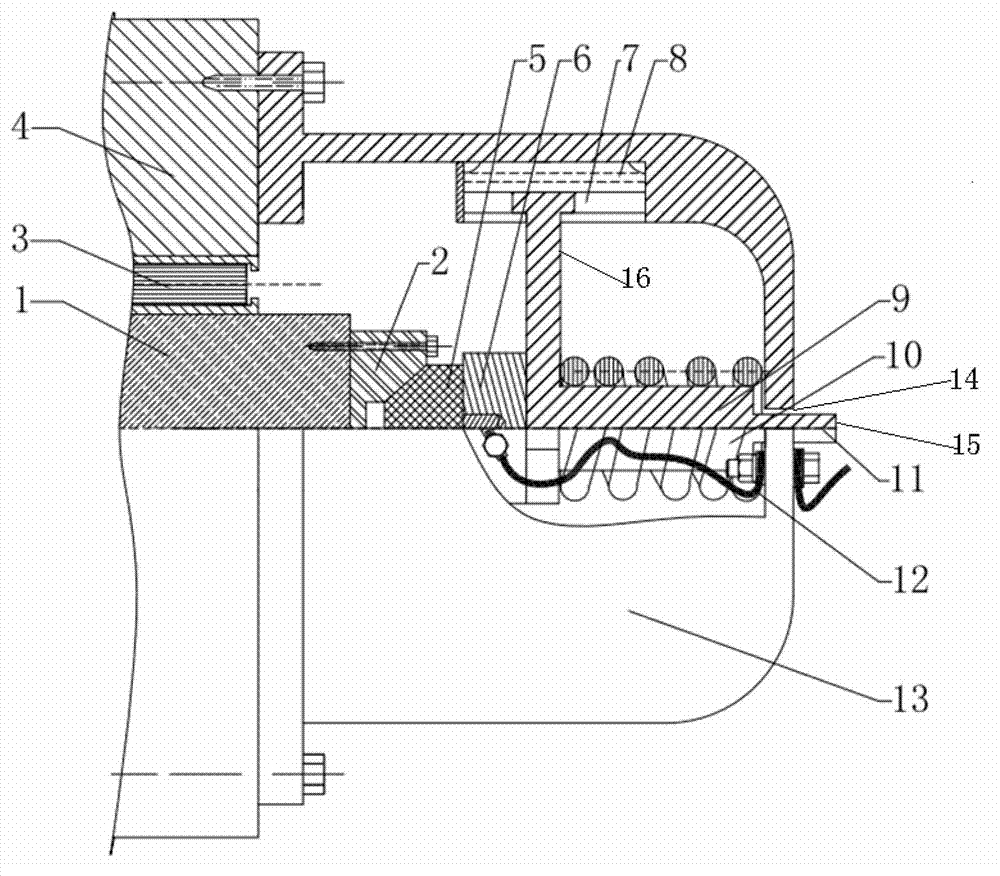

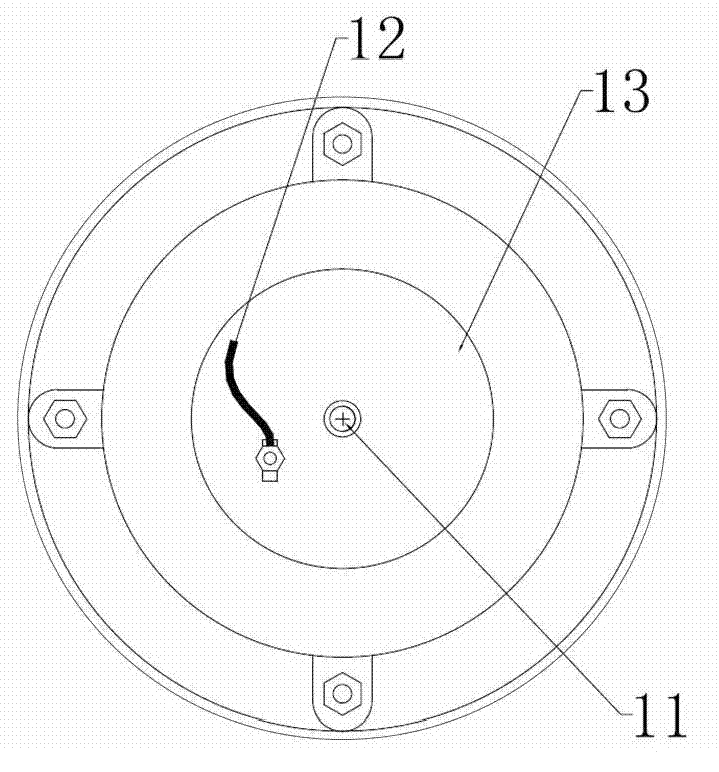

[0016] figure 1 Shows the axial sectional view of the grounding device, which consists of: wheel shaft 1, copper seat 2, bearing 3, shaft center contact cone 5, wire clip 6, insulating support frame 9, compression spring 10, wear indicator scale 11 and insulation The end cover 13; the axle 1 is connected with the bogie axle box 4 through the bearing 3, and the insulating end cover 13 is fixed on the bogie axle box 4 by fastening screws; the copper seat 2 is fastened on the outside of the axle head of the axle by screws; the axle center Contact cone 5, wire clip 6, chute 7, spring leaf 8, insulating support frame 9, compression spring 10, wear indicator scale 11, flexible wire 12 are installed in the insulating end cover 13; Fixed on the insulating support frame 9; the insulating support frame 9 is elastically supported by the spring leaf 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com