Automatic detection and pressing device for pcba board test

An automatic detection and driving device technology, applied in the direction of measuring devices, measuring device casings, printed circuit testing, etc., can solve problems such as natural bounce, plate fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

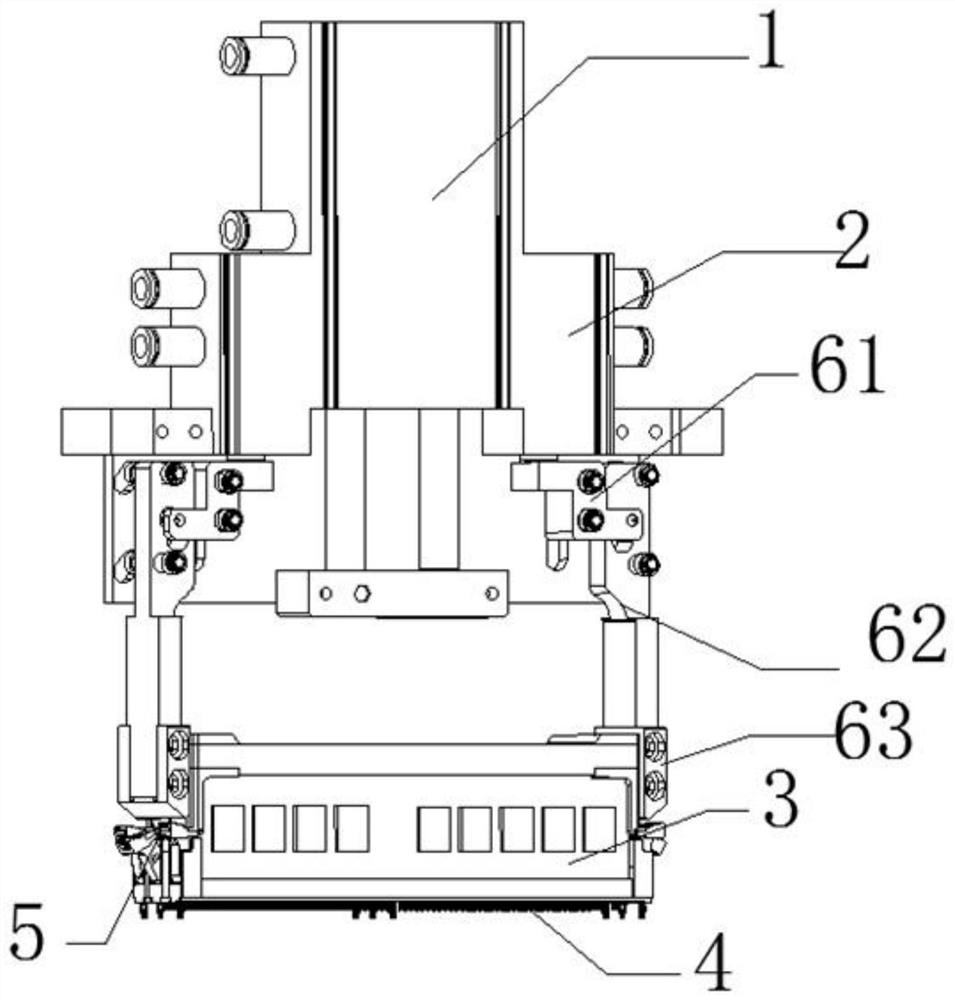

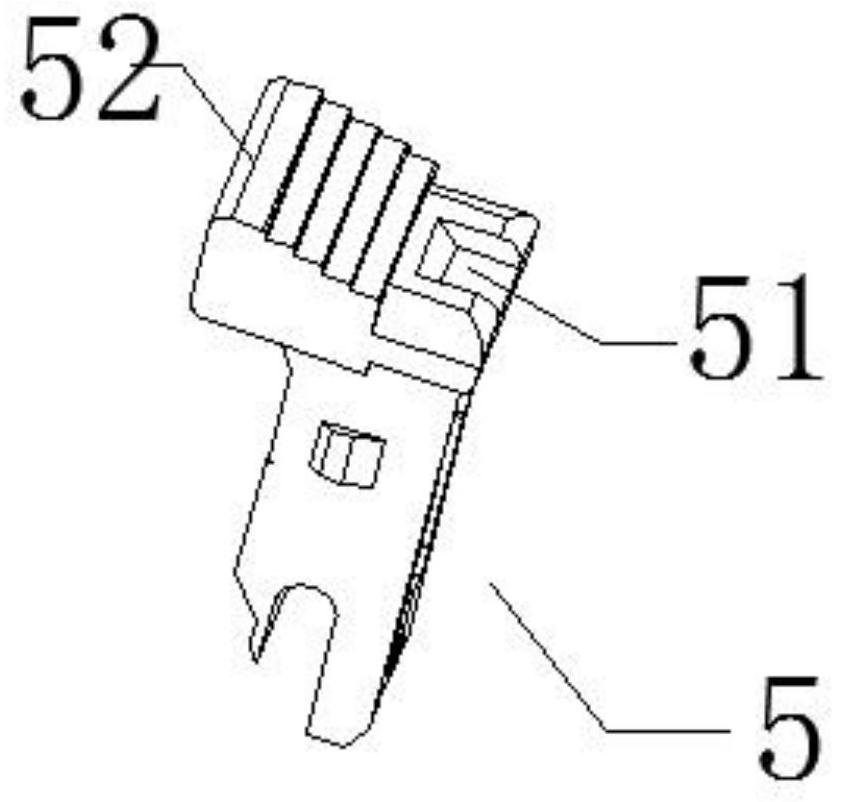

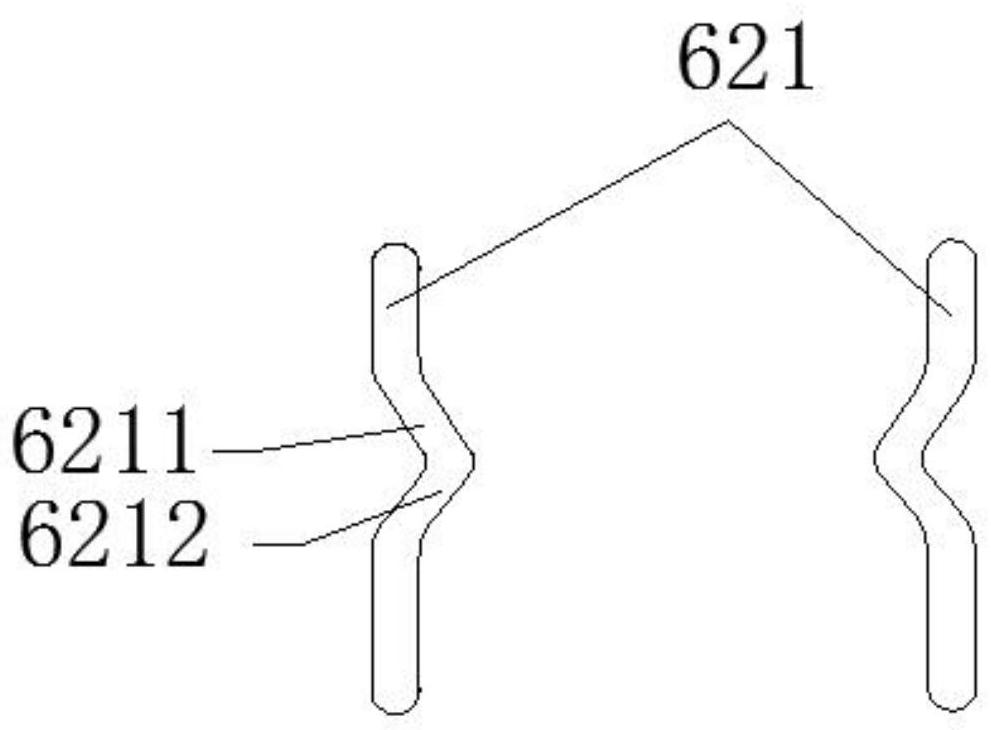

[0024] The automatic detection pressing device for PCBA board testing, the main components include: drive device 1 and drive device fixing seat 2 on both sides, memory module 3, DIMM slot 4, located at both ends of DIMM slot 4 and connected to DIMM slot 4 The toggle switch 5 at the bottom of the end can be partially rotated. When the memory stick 3 is inserted into the DIMM slot 4, the toggle switch 5 on both sides rotates and snaps into the buckle groove in the memory stick 3. Fix the memory stick 3 located in the DIMM slot 4 to ensure the normal program action of the PCBA board test; wherein, both sides of the automatic detection pressing device are provided with a DIMM slot buckle fixing bracket, and the drive device 1 includes a main drive Device, the side push drive device located on both sides of the main drive device, the main drive device is used to press down and push the memory module 3; the DIMM slot buckle fixing frame directly above contacts the power output end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com