Optical cable butt joint box for intelligent transformer station simulation test

A technology for intelligent substation and simulation testing, applied in the directions of light guide, optics, optical components, etc., can solve the problems of large impact on personnel and the environment, long construction period of optical cable, and weak plugging of the plug-in device. The effect of firmness, enhanced stability and airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

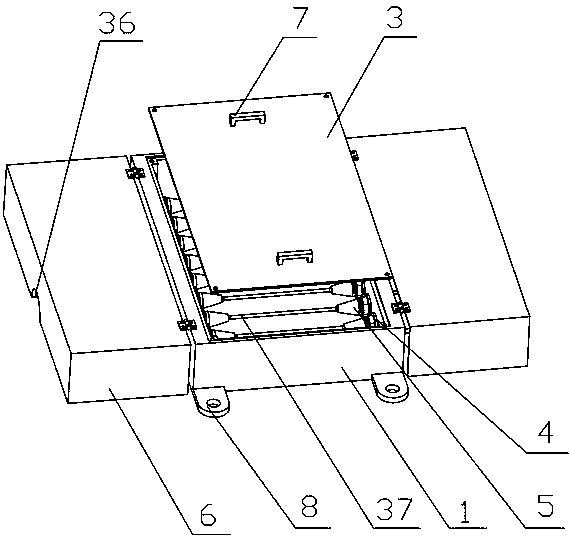

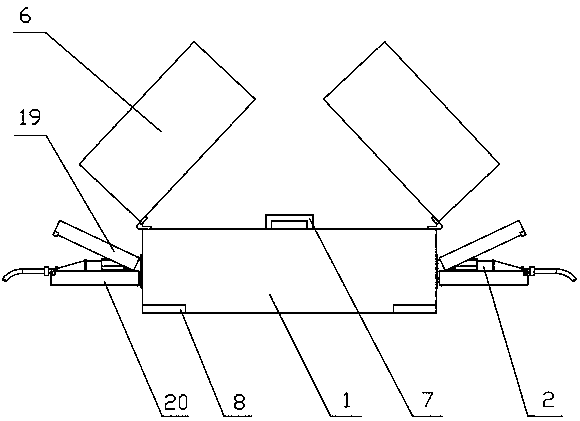

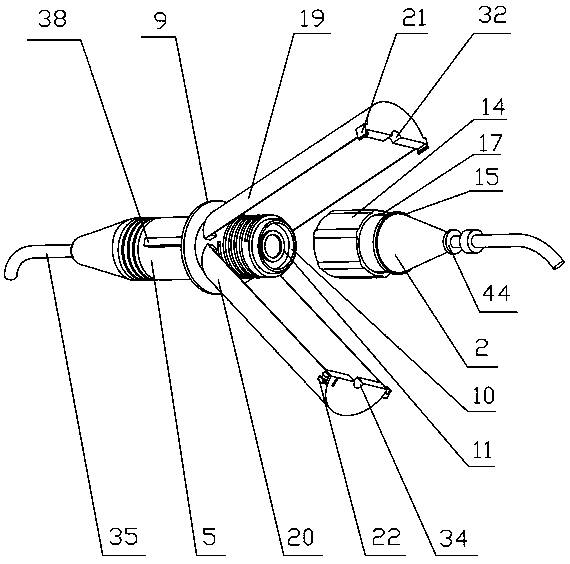

[0032] As shown in the figure, the characteristics of an optical cable docking box for smart substation simulation test include: a connection box 1, a plug 2; a box cover 3 is provided on the connection box 1, and the box cover 3 and the connection box 1 are connected by screws at corresponding positions , the side wall of the connection box 1 is provided with a first through hole 4, the first through hole 4 is equipped with a socket 5 that is plugged and matched with the through hole, the two ends of the socket 5 are provided with threads, and the two sides of the connection box 1 The corresponding socket 5 is connected by optical fiber 37; the plug 2 is corresponding to the socket 5 and the two are plug-in fit, the socket 5 is provided with a plug block 10 and a rubber gasket 11 fixedly connected to the end face of the socket 5, and the plug 2 is provided with The first groove 12 that slides with the plug 10, the fiber core 13 on the end face of the plug 2 corresponds to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com