A heating layer structure of food cooking equipment

A technology of cooking equipment and heating layer, which is applied in the direction of cooking utensils, heating devices, kitchen utensils, etc., which can solve the problems of inconvenient access, different dry and thin foods, troubles, etc., and achieve the effect of convenient eating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

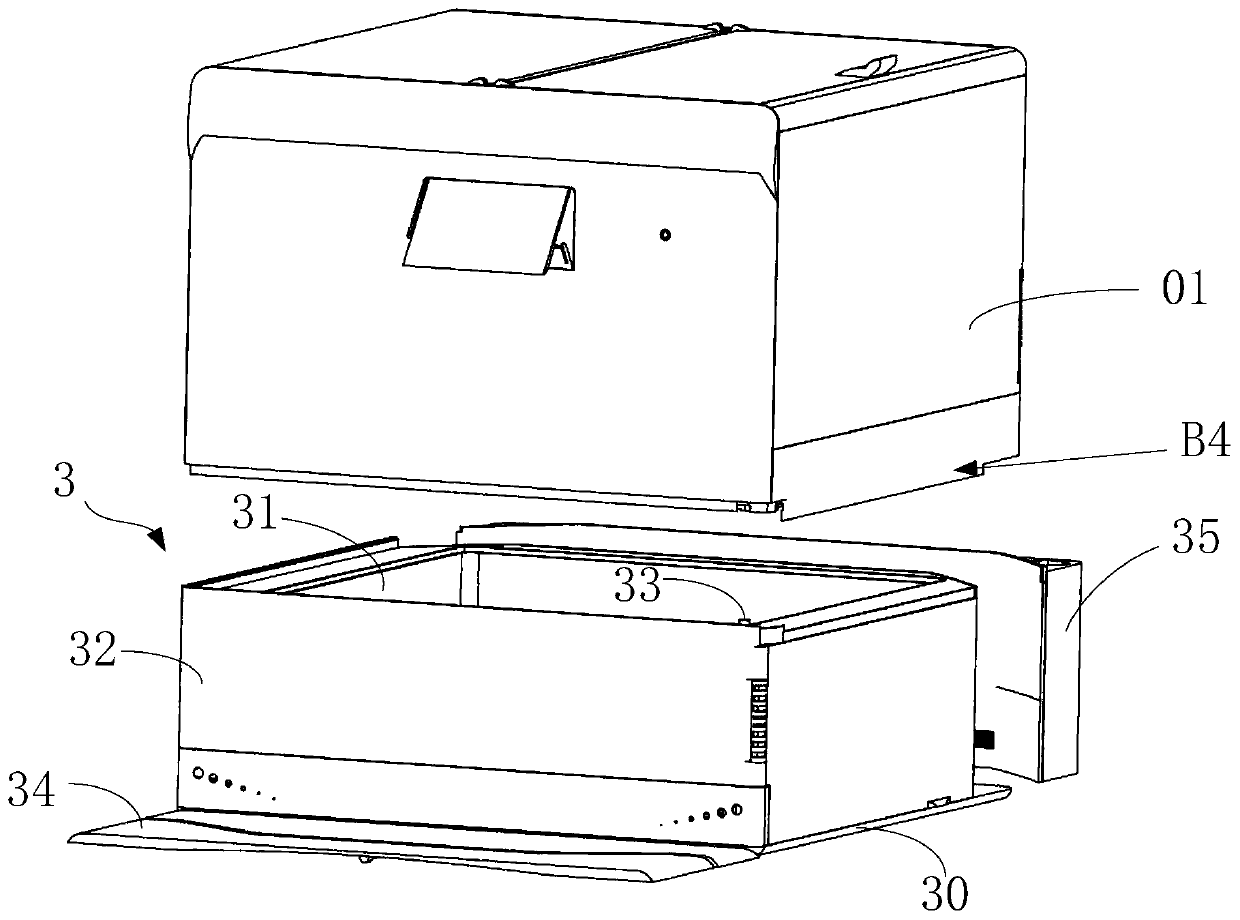

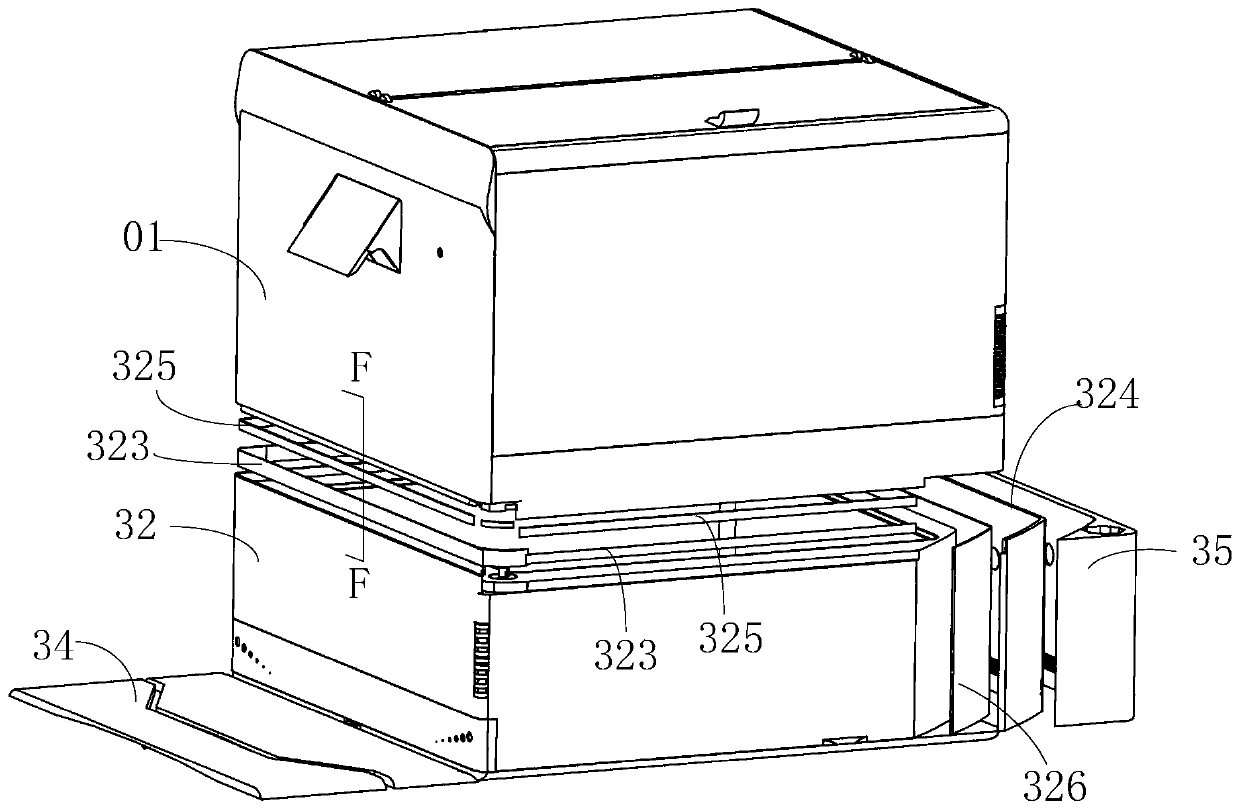

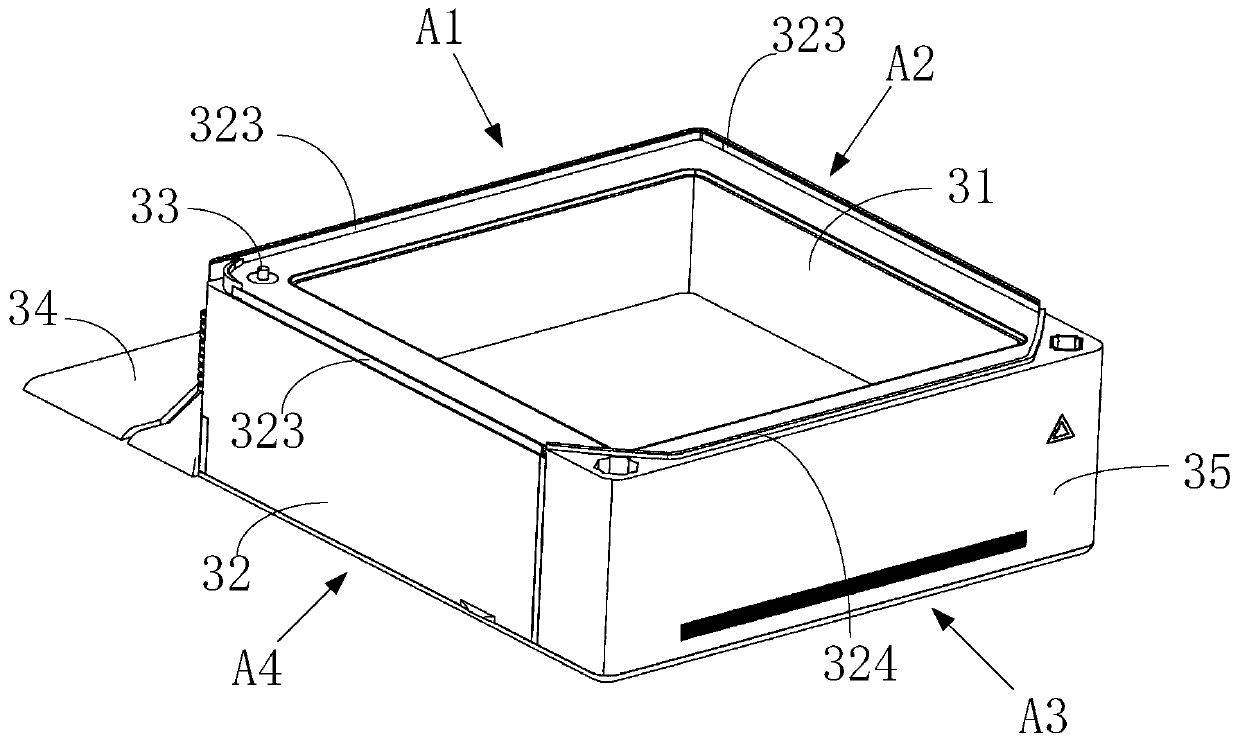

[0040] Such as Figure 1 to Figure 4As shown, a heating layer structure of food cooking equipment, the food cooking equipment includes an upper casing 01 and a heating layer 3 located below the upper casing 01, the heating layer 3 includes a main box body 32, which is arranged in the main box The pot body 31 in the body 32, the heating plate 36 arranged under the pot body 31, and the detection mechanism 4 arranged under the pot body 31 for detecting the pot body; the upper casing 01 is sealed above the heating layer 3, and the A sealing structure is provided between the lower end of the casing 01 and the upper end of the heating layer 3 , and the heating layer 3 is horizontally rotatably arranged in the food cooking equipment, and can be rotated out from below the upper casing 01 in the horizontal direction. The heating layer 3 has a heating position located below the upper casing 01 and an external feeding position located at the lower casing; during the heating process, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com