Test device and method for analyzing influence of winding defect induced heat on oil paper insulation performance

A technology of oil-paper insulation and test equipment, which is applied in the direction of measurement equipment, test ship construction, and test dielectric strength, etc., and can solve problems such as inability to observe, inter-strand short circuit, and metal welding of oil-paper insulation windings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

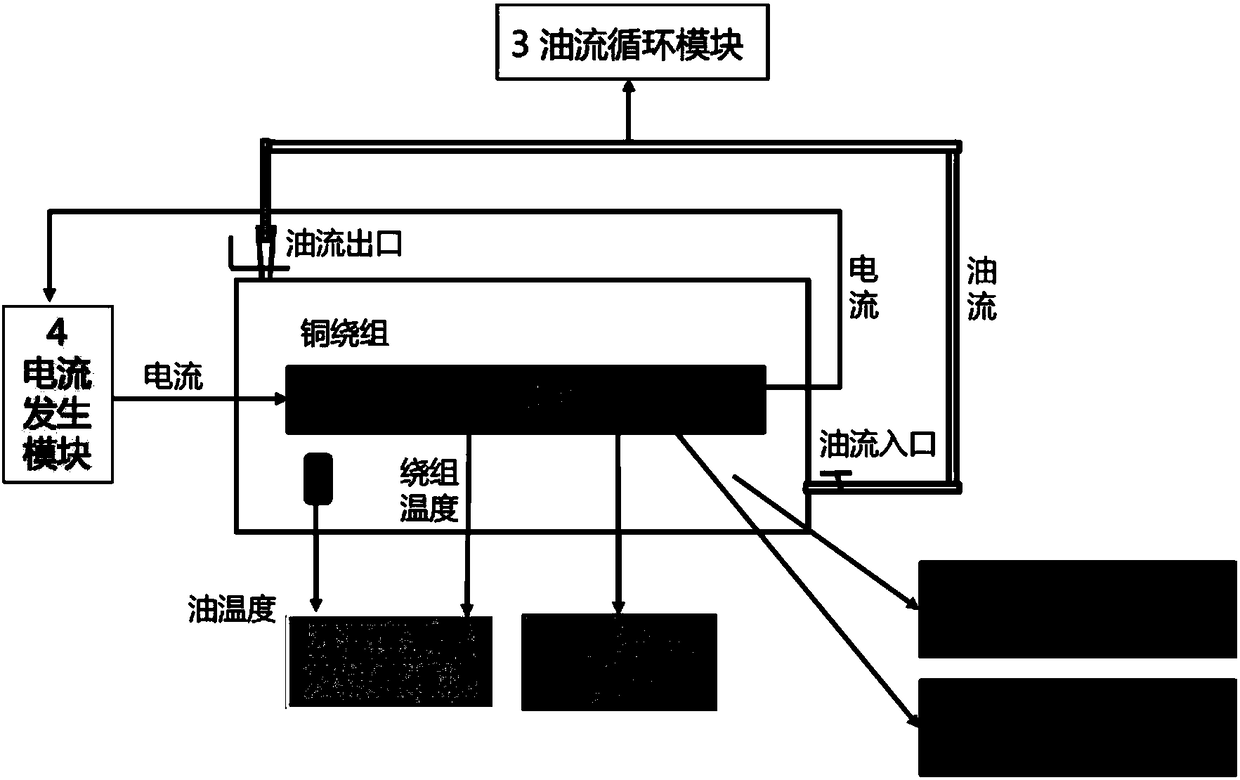

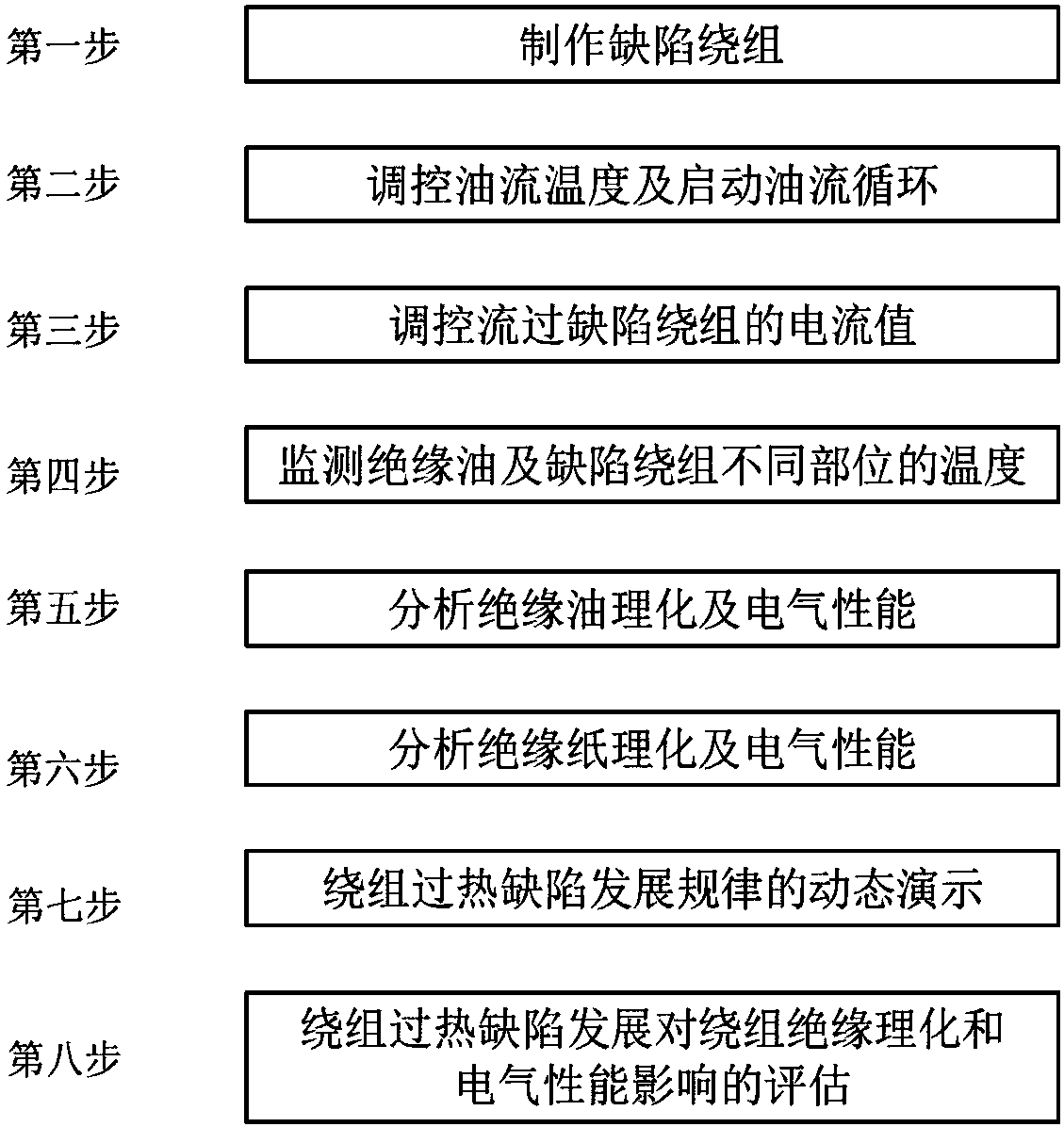

[0039] Such as Figure 1-3 Shown, the present invention comprises the following steps:

[0040] (1) Making defective windings

[0041] According to the capacity and voltage level of the transformer, test oil-paper insulation defective windings with defect types such as metal welding, deformation, broken strands, short-circuit between strands, or oil-paper bulges are respectively constructed. The oil-paper insulation windings can be simple long strip windings, or It can be the actual coil-wound winding in the transformer, and the winding material is the same as that of the corresponding transformer winding to complete the construction of the defective winding module.

[0042] (2) Build a temperature measurement and sensing module

[0043]On the basis of the first step, multiple sets of temperature sensors are used to complete the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com