A Method of Improving the Slip Torque of Friction Torque Limiter

A torque limiter and friction torque technology, which is applied in the field of electromechanical equipment, can solve problems such as low pass rate, poor reliability, and jumping phenomena, and achieve the effect of improving slipping torque, smooth slipping torque, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

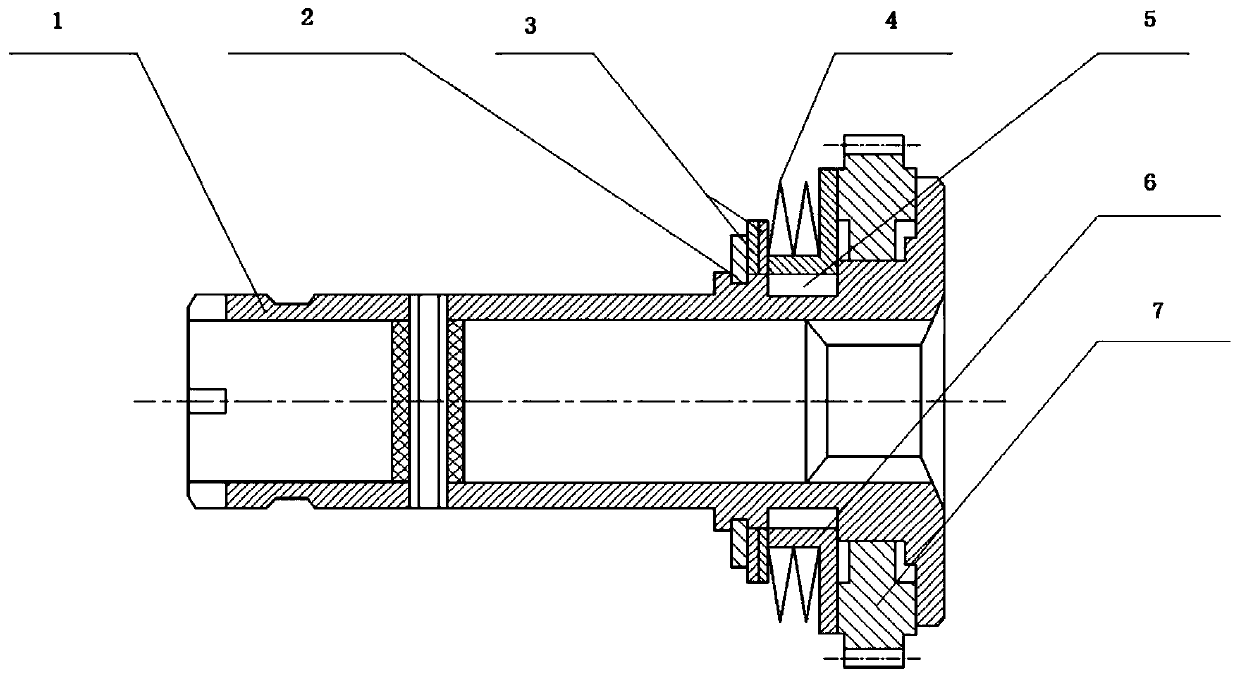

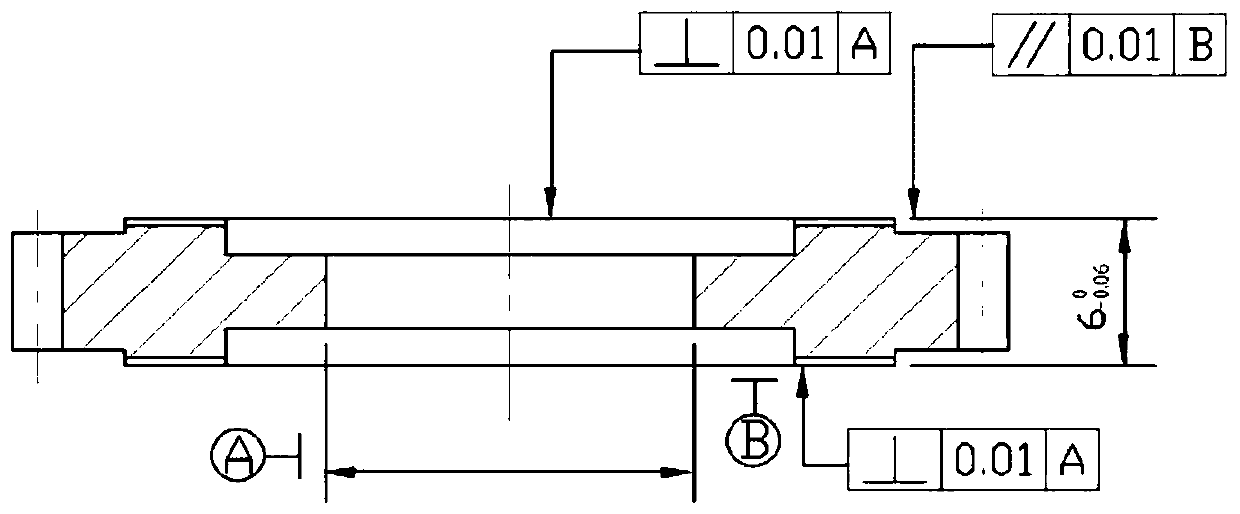

[0015] Attached below figure 1 , 2 The present invention is described in further detail.

[0016] A method for improving the slip torque of a friction torque limiter, characterized in that it comprises the following steps:

[0017] (1) Grinding both ends of 130-tooth gear parts;

[0018] (2) Engraving net pattern on both ends of 130-tooth gear parts;

[0019] (3) Pre-assembled in the torque limiter; first use a brush to clean the surface of the friction plate to remove excess oxides on the surface, apply grease on the 130-tooth gear and assemble it with other parts to form an assembly, and manually rotate it about 5 times left and right , Disassemble the components for cleaning, and use a brush to scrub the surface of the 130-tooth gear. The texture on the surface of the 130-tooth gear should be clearly visible, and then reassemble the components for torque adjustment.

[0020] The grinding of the two ends of the 130-tooth gear part requires that the perpendicularity relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com