An anti-tangle rope winch

An anti-chaos rope and winch technology, which is applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of hoisting wire ropes, affecting the normal use of winches, accelerating wire rope wear and service life, etc., so as to prevent rope chaos and solve problems The problem of rope chaos in the winch and the effect of unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

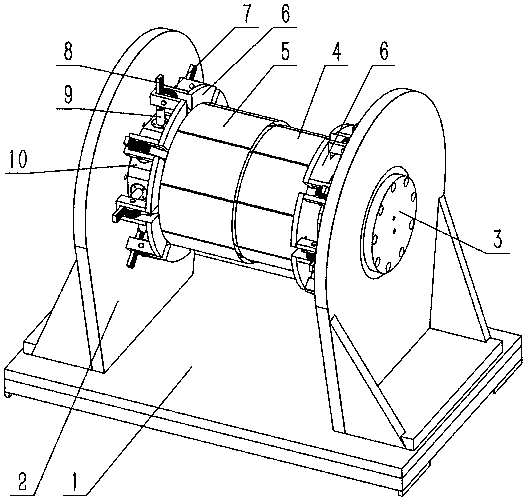

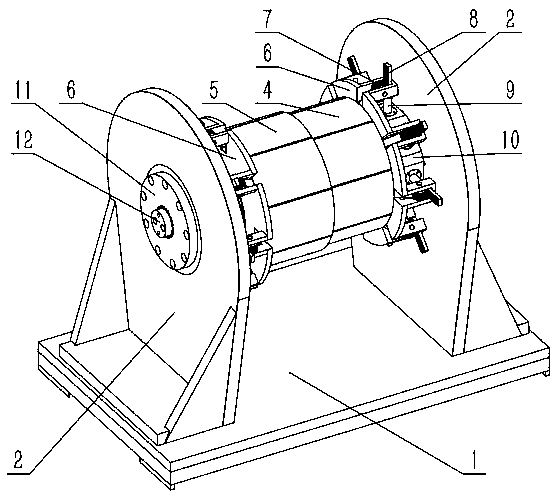

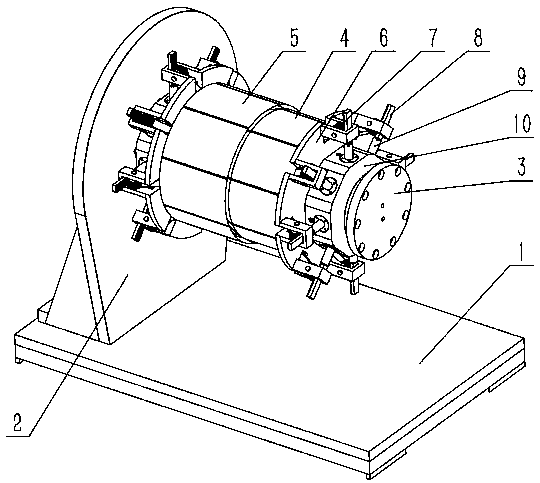

[0023] Example: such as Figure 1 to Figure 12 The shown a kind of anti-disorder rope winch comprises a winch support 1, and two roller supports 2 are vertically installed on both sides of the winch support 1 respectively, and each roller support 2 is provided with a through hole, and the through hole of one of the roller supports 2 A non-power end seat 3 is installed on the top, and a power end seat 11 is installed on the through hole of the other roller bracket 2. An end seat shaft is arranged on the inner side of the non-power end seat 3, and a spline groove is arranged at the center of the power end seat 11, and is connected with The splines at one end of the fixed-axis drive motor 12 are installed in cooperation, and the axis of the fixed-axis drive motor 12 coincides with the axis of the through hole on the power end seat 11. A roller 13 is also arranged between the two roller supports 2 , one end of the roller 13 is sleeved on the shell of the fixed shaft drive motor 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com