Deflection rope guide

A rope unwinding device and rope arranging technology, applied in the field of rope unwinding devices, can solve problems such as poor auxiliary rope winding effects, achieve the goal of suppressing adverse effects, solving the problem of rope disorder, and reducing the speed of broken wires and final failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

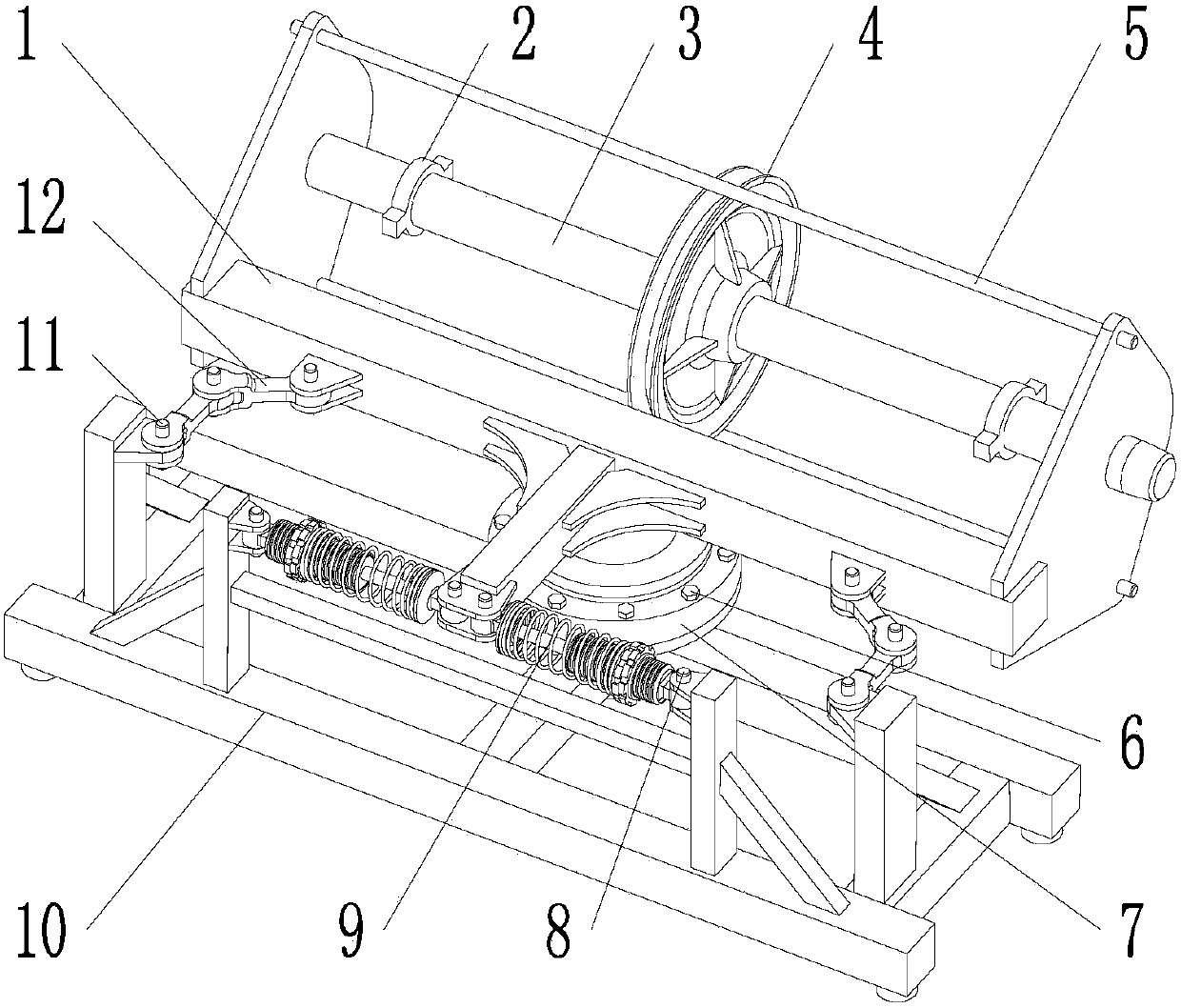

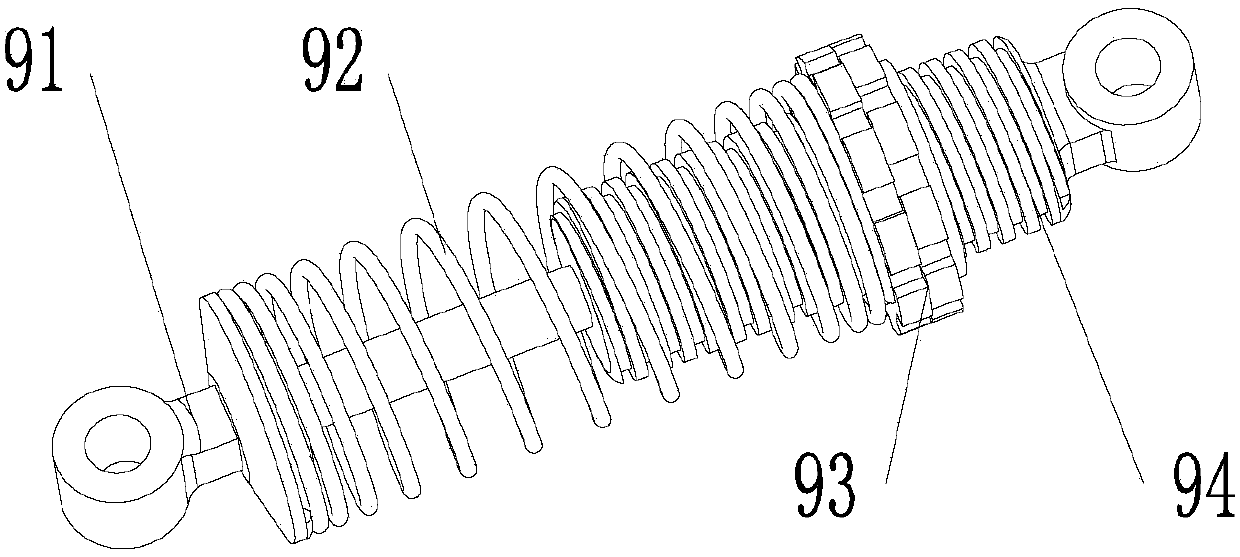

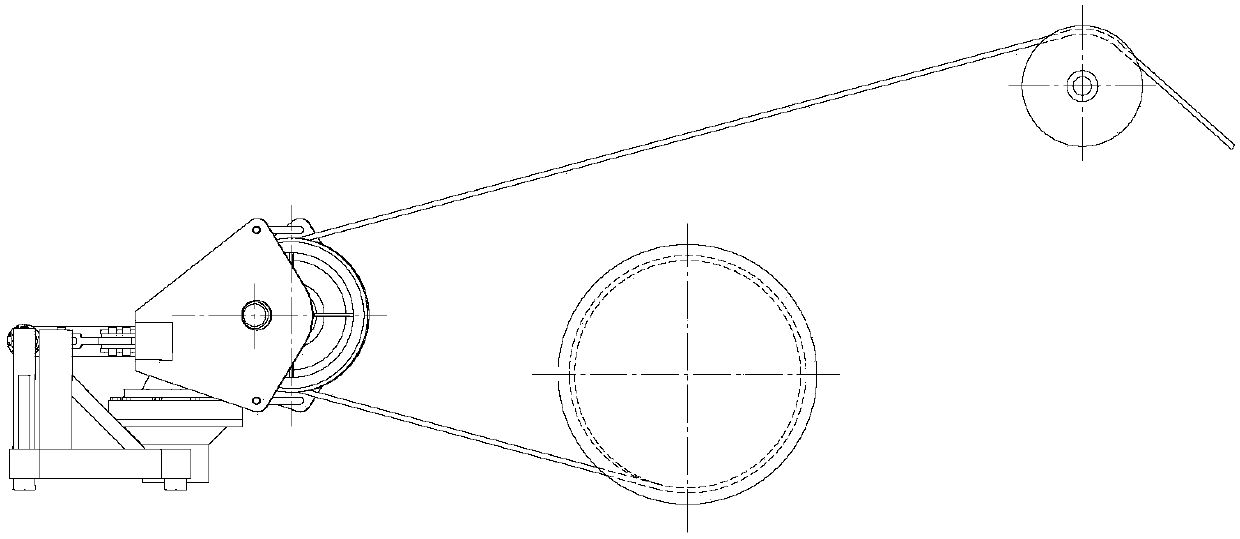

[0014] Such as image 3 , 4 As shown, the deflection rope puller is suitable for the rope discharge method relative to the broken line rope groove drum. After wire rope is drawn from broken line rope groove reel, walk around the rope groove of arranging rope pulley 4, then, wind out from rope pulley rope groove. The rope pulley 4 divides the wire rope between the broken line rope groove reel and the rope pulley into two sections with different lengths. The rope pulley 4 slides back and forth on the rope shaft 3 along with the winding of the steel rope on the broken line rope groove reel under the effect of the axial resultant force of the two sections of steel ropes. The upper deflection frame 1 and the clamp 2 installed thereon, the rope shaft 3, the rope pulley 4 and the rope retaining bar 5 also deflect under the effect of two sections of wire ropes relative to the radial resultant force of the rope pulley 4. Whenever the rope pulley 4 slides past the midpoint of the rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com