Crankshaft rope arrangement and its installation structure

A rope arranging device and crankshaft technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of wire rope damage, increase the declination angle of the rope entering the rope, and the influence of the stability of the rope, so as to solve the problem of rope disorder. , the effect of prolonging the service life, reducing the speed of wire breakage and eventual failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

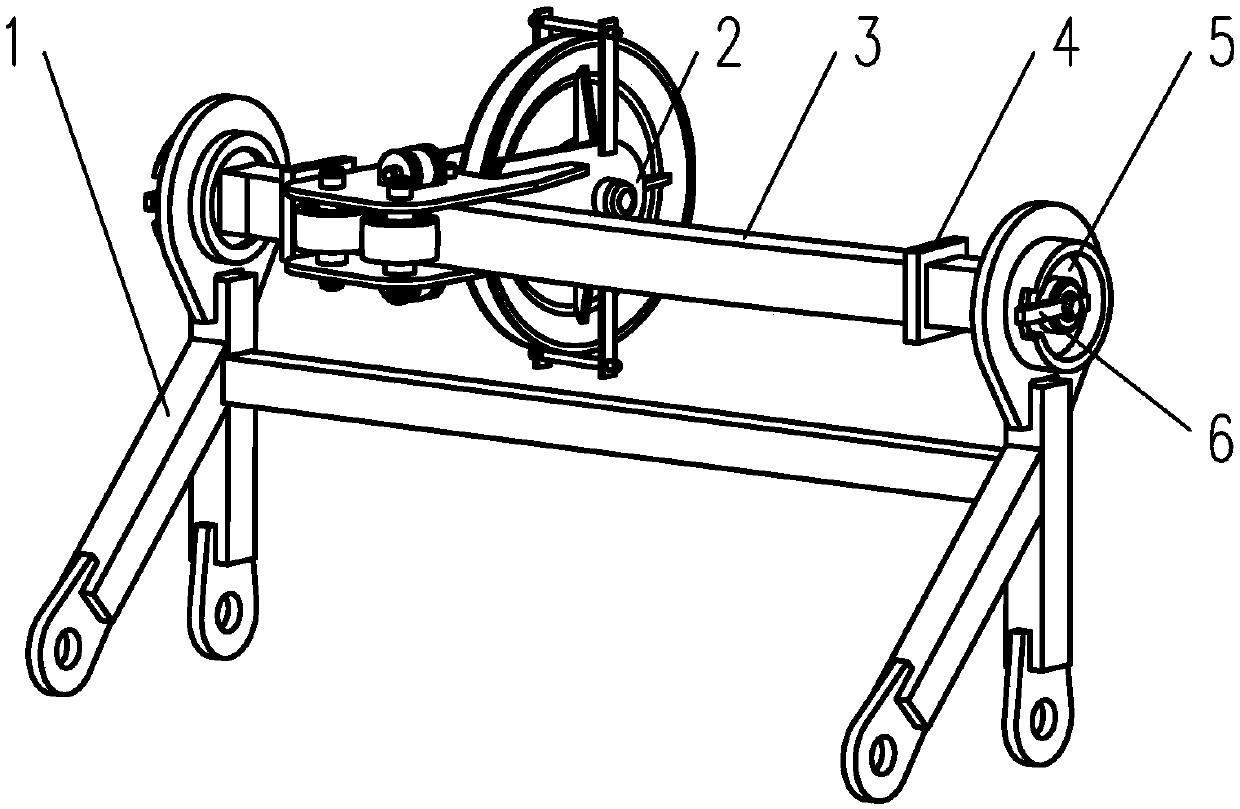

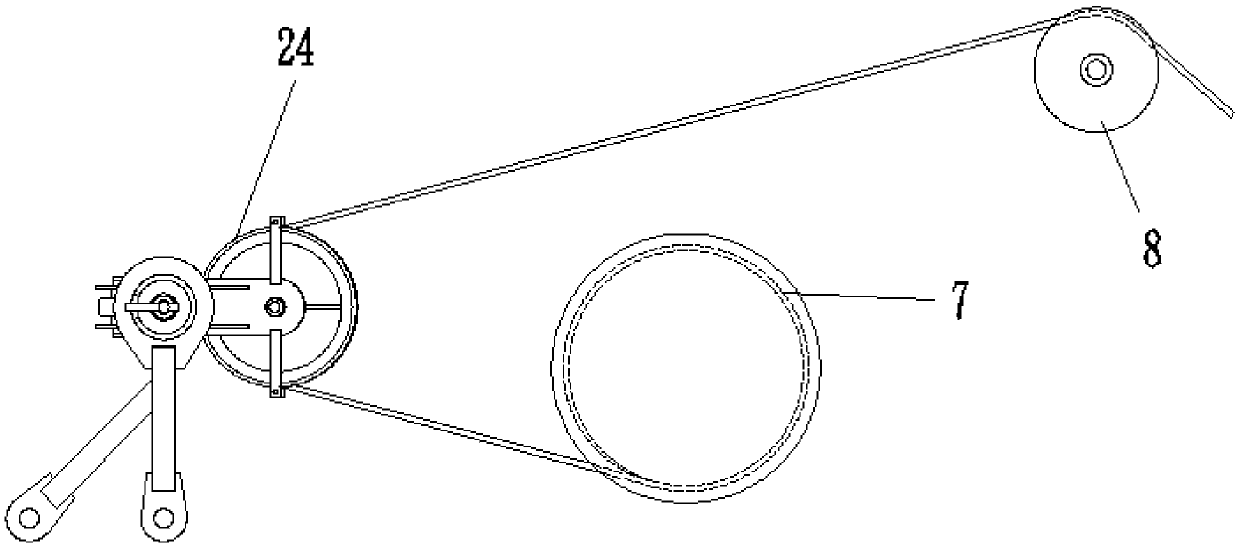

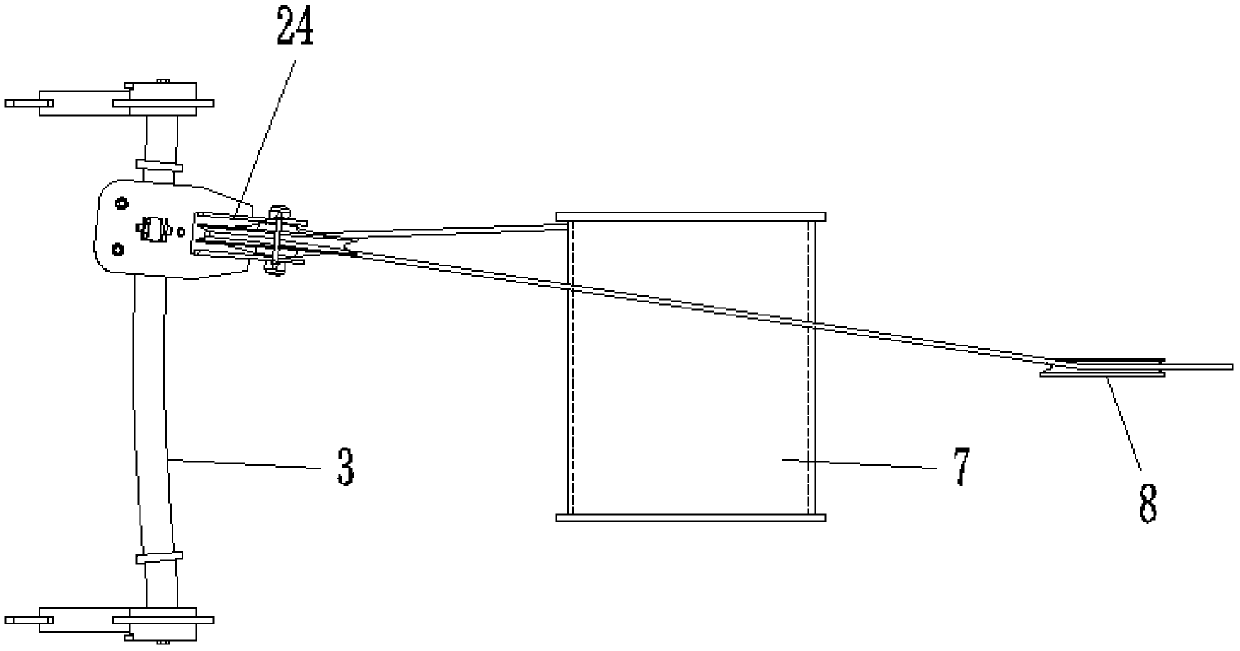

[0025] like figure 1 , Figure 4 , Figure 5 As shown, the crankshaft rope guide includes a bracket 1, an offset device 2, and a crankshaft 3;

[0026] The cross-section of the track position of crankshaft 3 is a rectangular shape, and its upper and lower ends are side flat track surfaces 32, and both sides are curved track surfaces 33, and the curved track surfaces 33 have arc track surfaces; among the two curved track surfaces 33, One side of the convex surface is the main track surface, and one side of the concave surface is the auxiliary track surface; the crankshaft 3 is arranged laterally on the bracket 1;

[0027] Offset device 2 comprises offset frame 21, and offset frame 21 is provided with side guide wheel 22, row rope pulley 24, inner guide wheel 25, roller 26, and offset device 2 is sleeved on crankshaft 3, and the rim of roller 26 Close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com