Regenerated self-embedded plate and application thereof

A self-embedded, main board technology, applied to pavement, roads, roads and other directions paved with prefabricated blocks, can solve the problems of a large amount of construction waste and difficulty in recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

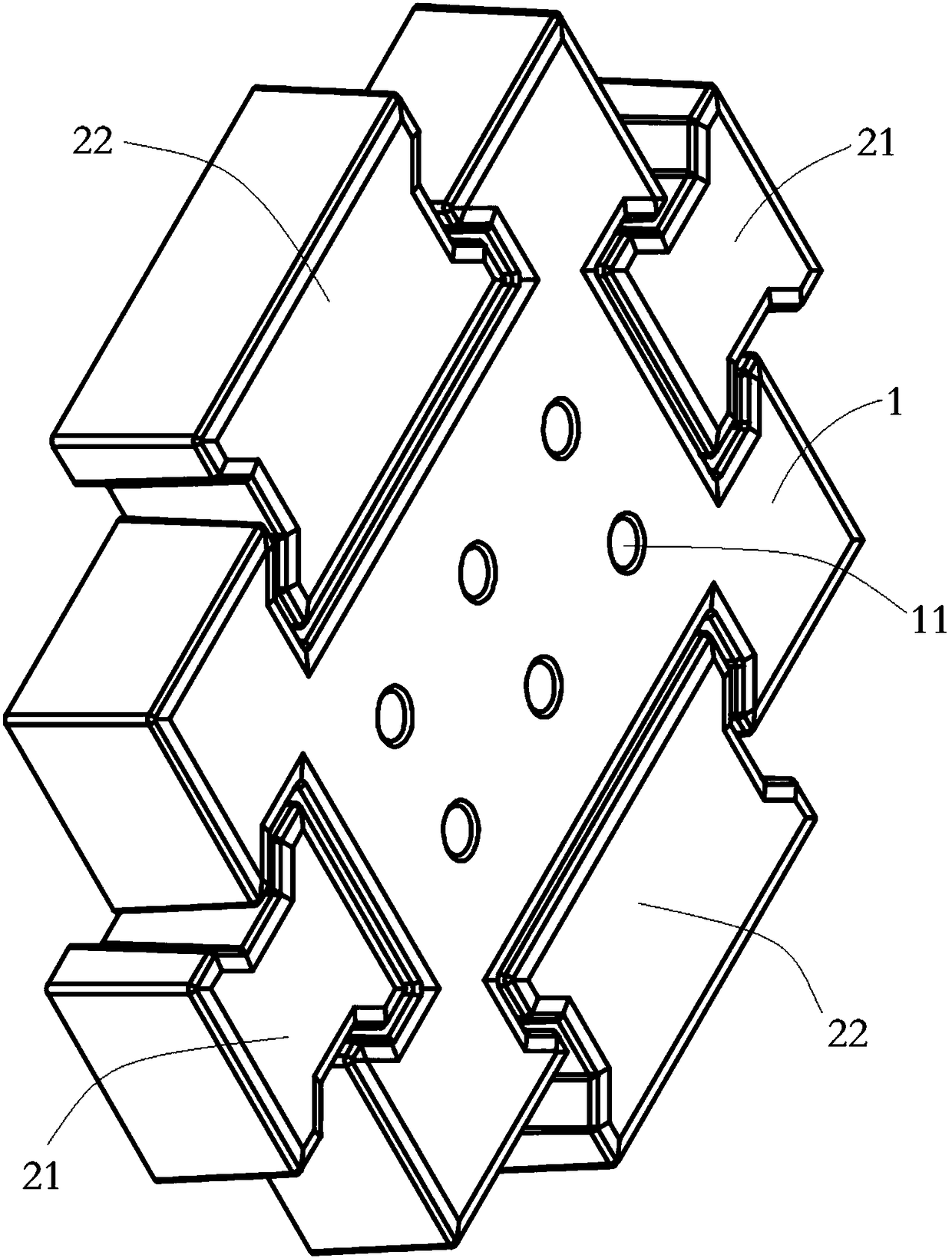

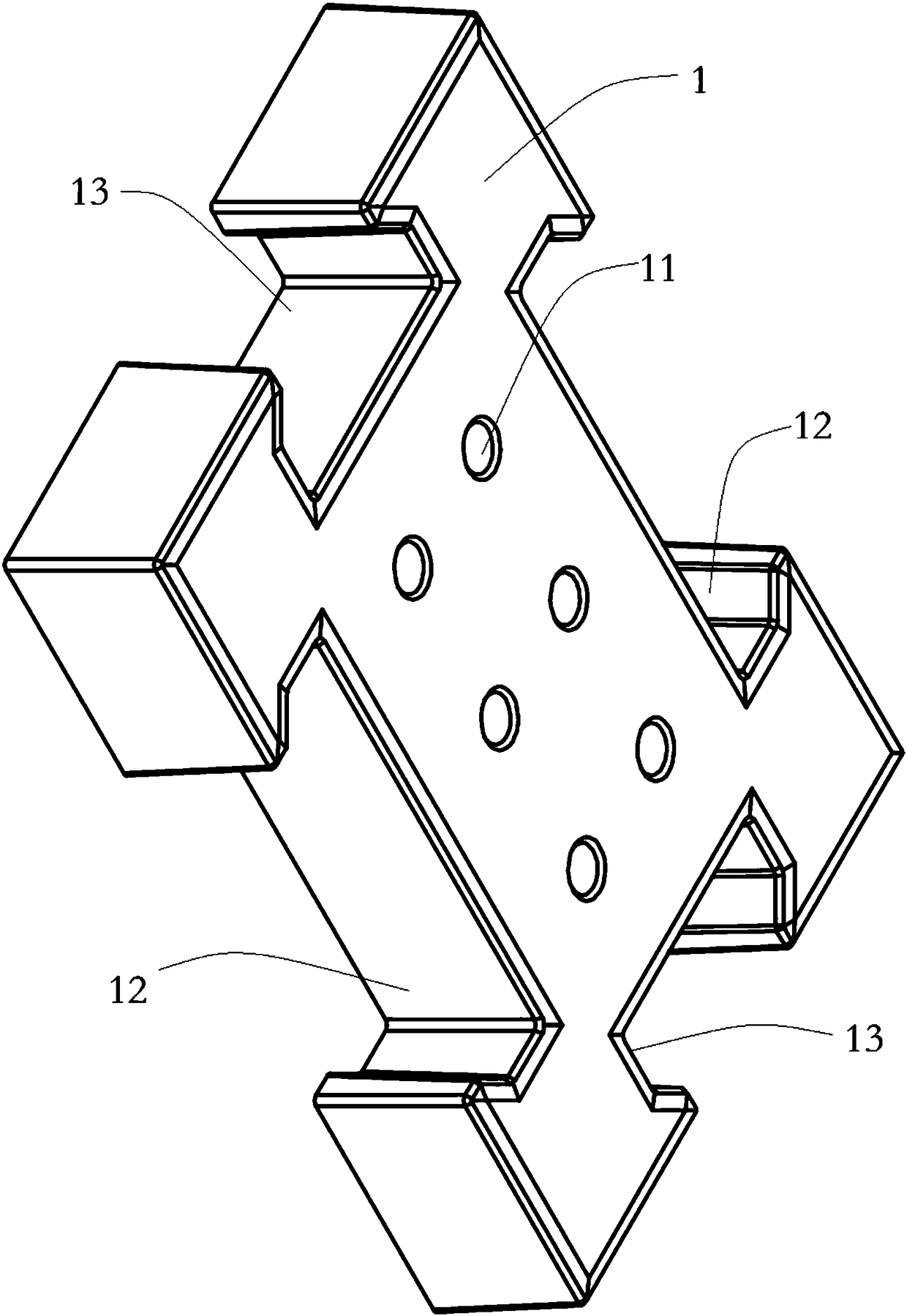

[0036] figure 1 A preferred embodiment according to the invention is shown. In this embodiment, the regenerated self-panel is formed by mating and splicing the main board 1 and the fastener. Splicing is carried out in the way of mortise and tenon structure, as follows figure 1 shown.

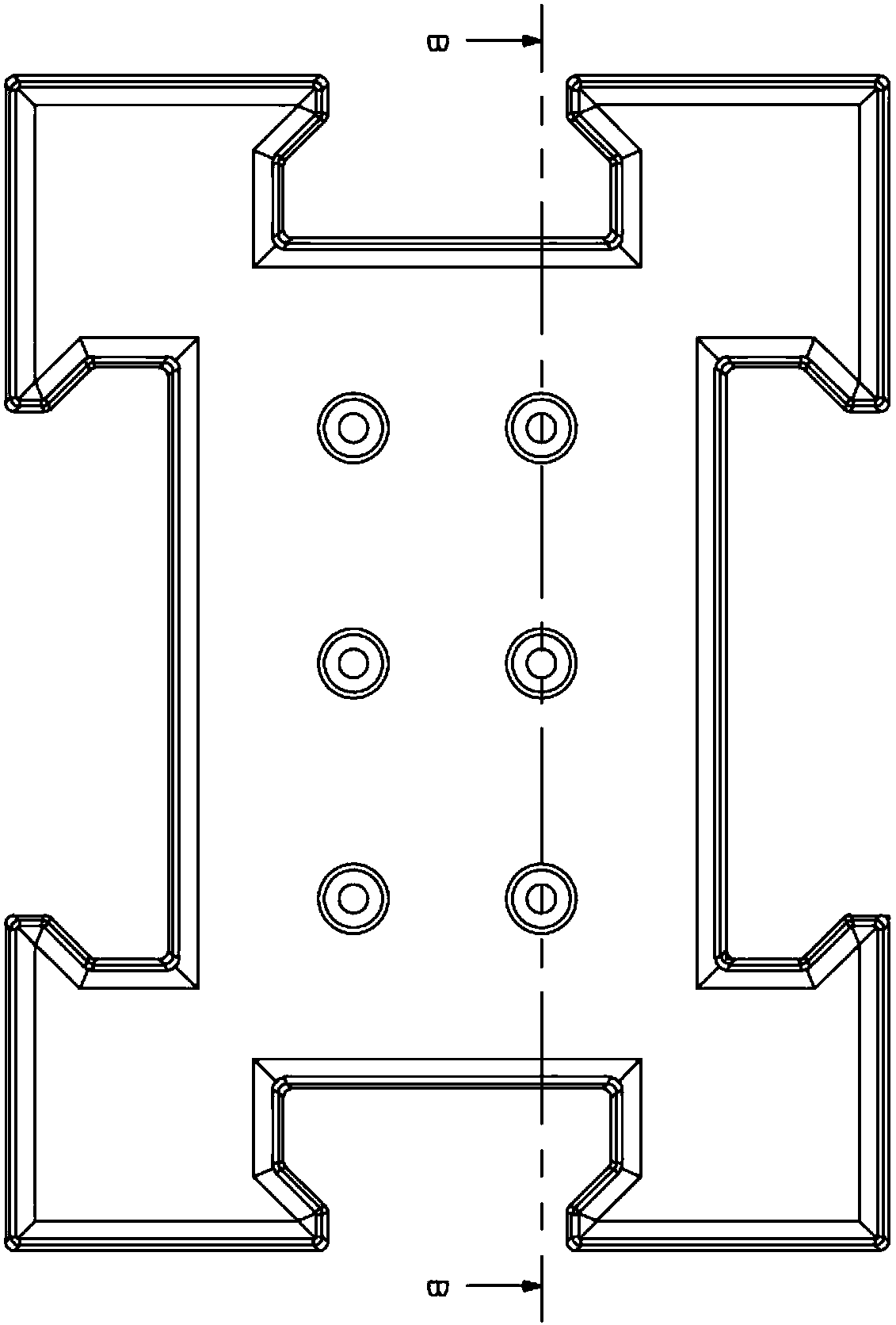

[0037] Such as Figure 2-4 As shown, the main board 1 is provided with a hole 11 passing through the upper and lower surfaces of the main board 1, and the diameter of the hole gradually decreases from top to bottom. A side length of the main board 1 is provided with a groove, and the groove is located in the middle section of the side length of the main board 1 . In this embodiment, the grooves include two first grooves 13 and two second grooves 12 .

[0038] In this embodiment, the fasteners include a first fastener 21 and a second fastener 22 , which are respectively matched with the first groove 13 and the second groove 12 . The fastener is a complete structure. In order to facilitate t...

Embodiment 18

[0054] Embodiment 1.8 is an example of the specific dimensions of the main board and fasteners regenerated from the panel in embodiment 1

[0055] The length of the groove from the two endpoints of the side length of the main board 1 is equal, that is, the groove is located in the middle of the side length. The maximum width of the groove is 100mm, the minimum width of the groove is 80mm, the ratio of the two is 10:8; the depth of the groove is 60mm, the length of the main board 1 is 400mm, the ratio of the two is 1:6.7; the main board 1 The width of the groove is 250mm, and the ratio of the depth of the groove to the width of the main board 1 is 1:4.2. The regenerated self-panel of 0.5 square meters includes 4 complete main boards 1, and the thickness of the regenerated self-panel is 5 cm.

[0056] Embodiment 1.9 is an example of the specific dimensions of the main board and fasteners regenerated from the panel in embodiment 1

[0057] The length of the groove from the two e...

Embodiment 2

[0061] Image 6 It is another embodiment of the main board in the present invention, and the holes in this embodiment are square holes. Others are similar to Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com