Edge folding and pressing process

A technology and edge bending technology, which is applied in the field of folding and pressing dead edges, can solve the problems of small area and difficult pressing of plates, and achieve the effect of saving manpower, material resources and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

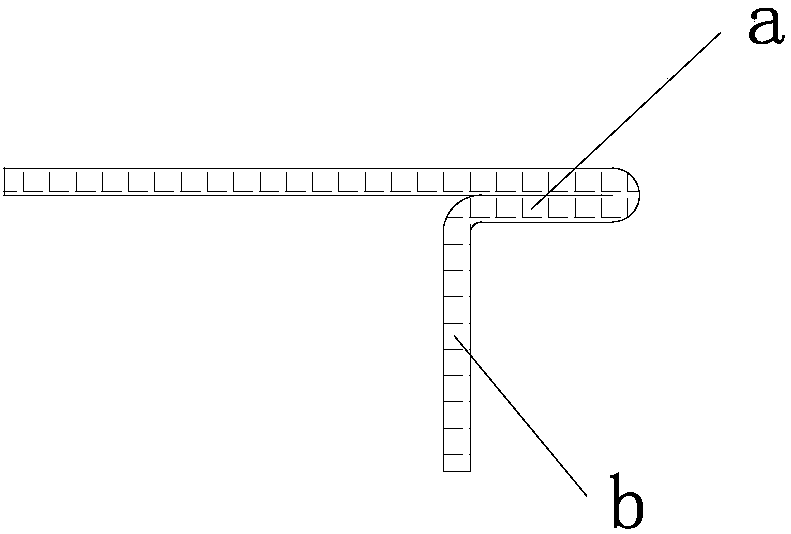

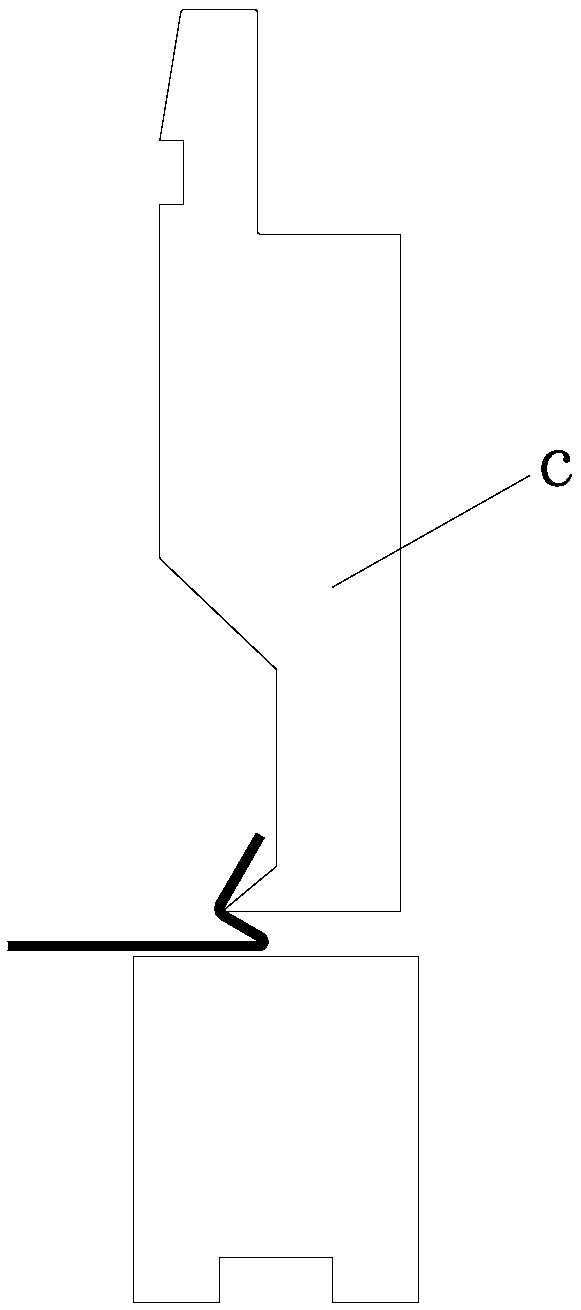

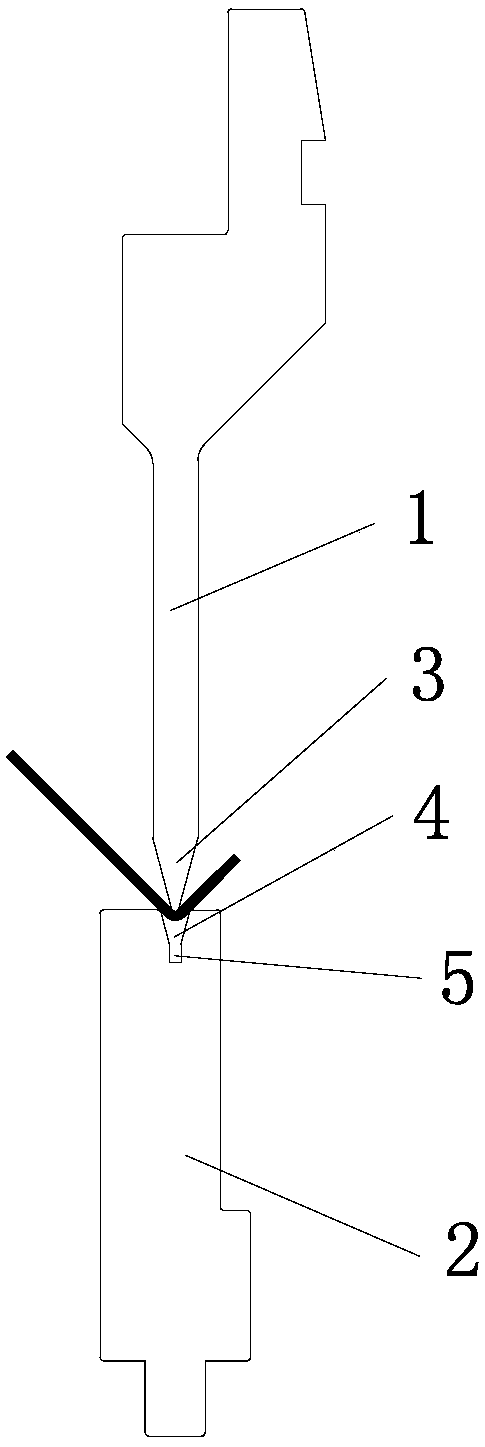

[0020] see Figure 3-4 , the bending mold includes an upper die bending head 1 and a lower die bending block 2, the bottom of the upper die bending head is a bending knife 3 with a sharp angle of 30°, and the lower die bending block corresponds to the The bending knife is provided with a bending groove 4 matching the bending knife, and the bottom of the bending groove has a notch 5 extending downwards, and the width of the notch is greater than one material thickness. see Figure 5 , the flattening mold comprises an upper mold pressing block 6 and a lower mold pad 7, one side of the lower mold pad has a downward groove, and a piece 8 is fixed in the groove, and the piece There is an insertion gap 9 with the side wall of the groove.

[0021] The folding and pressing dead edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com