Leather flattening mechanism of vacuum drying machine

A technology of a vacuum dryer and an unfolding mechanism, which is applied in the directions of leather drying, leather wrapping/stretching, etc., can solve the problems of cumbersome, waste of manpower and material resources, and low efficiency of leather drying, and achieve the effect of improving work efficiency and reducing manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

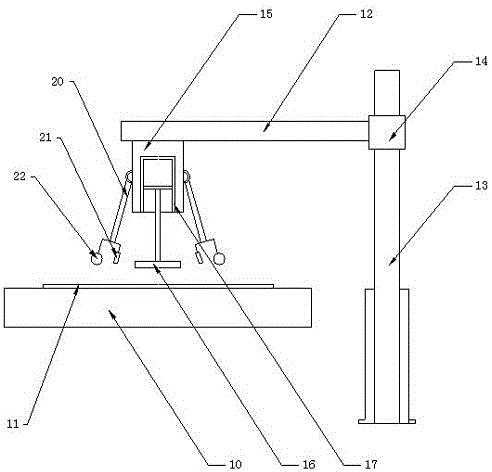

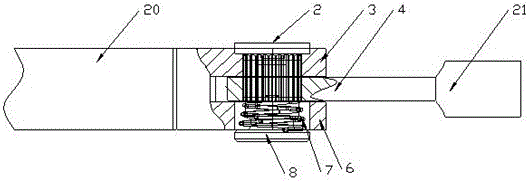

[0035] Such as Figure 1-Figure 6 Shown a kind of vacuum drying machine skin spreading mechanism, described vacuum drying machine comprises a drying platen 10, is covered with leather 11 on the drying platen 10, and this skin spreading mechanism is used for spreading the leather on the drying platen Flat, the first structure of the skinning mechanism is: including

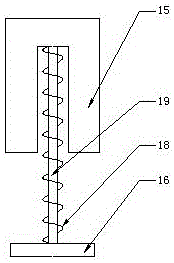

[0036] A lifting mechanism, the lifting mechanism includes a cantilever 12 horizontally arranged on the top of the drying table 10, a lifting column 13 vertically arranged at the side end of the drying table 10, on the lifting column 13 there is a The lifting slider 14 that moves up and down reciprocatingly in the direction, the lifting slider 14 is driven by the lifting drive cylinder to move up and down, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com