A modular bridge erecting mechanism

A modular and bridge-section technology, which is applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve the problems of on-site road environment damage, affecting the time of mechanized bridges, and poor bearing capacity of on-site road conditions, so as to achieve strong site adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

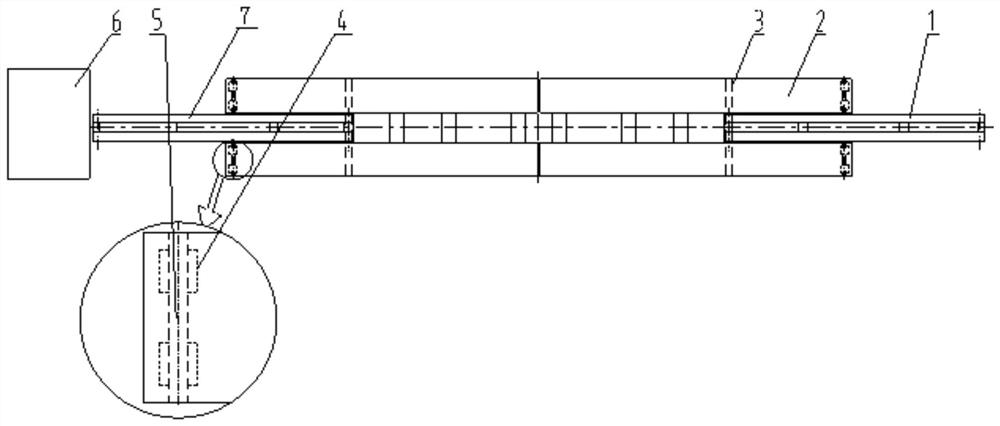

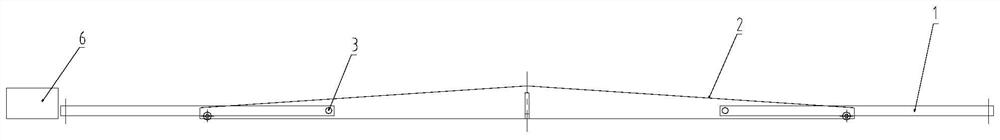

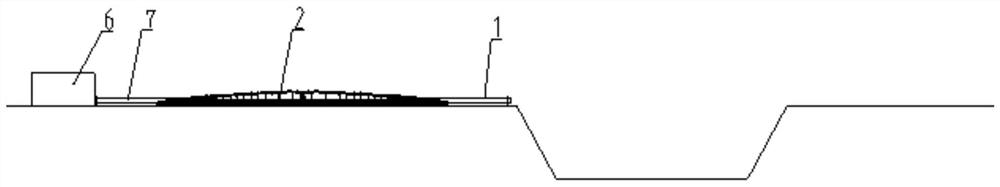

[0019] as attached figure 1 with 2 As shown, the present invention provides a modular bridge erection mechanism, which includes a support rod 1, a push rod 7, a modular bridge section 2, a rotating shaft 3, a roller 4, a roller shaft 5 and a propulsion power unit 6, wherein, The modular bridge section 2 is an integrated overall structure, and its length is greater than the width of obstacles to be crossed;

[0020] One end of the modular bridge section 2 is fixedly connected with the push rod 7, the other end of the modular bridge section 2 is hinged with the support rod 1 through the rotating shaft 3, and the roller 4 is installed on the bottom surface of the modular bridge section 2 through the roller shaft 3 , so that the modular bridge section 2 can move more conveniently under the push of the propulsion power unit 6 .

[0021] The erection process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com