Electric chair on wire

A technology of electric chairs and driving wheels, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as poor work efficiency, heavy labor of workers, and aggravated construction costs and operating risks of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

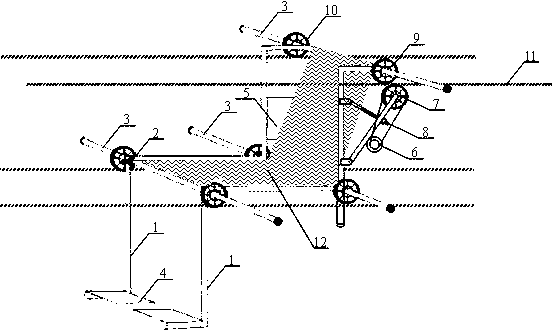

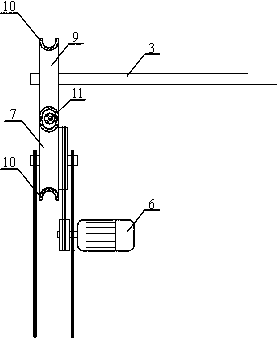

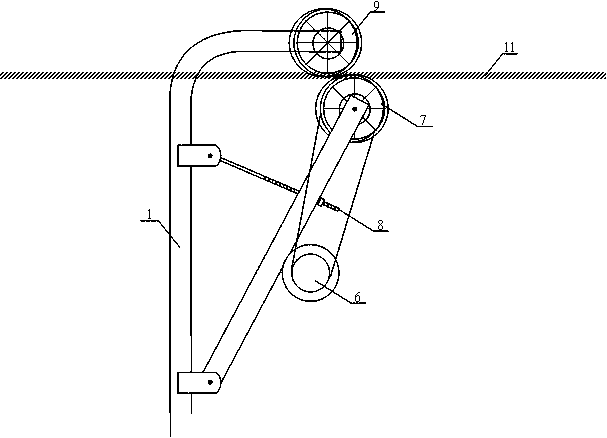

[0012] As shown in the figure, it is an electric chair on the line. The electric chair uses light and thin steel pipes to make two curved guards 1, and a hoop 2 is arranged at the bend to connect with the horizontal axis 3. The lower section is also equipped with a footboard 4. The left side of the upper section is provided with a battery box 5, the right one is provided with a motor 6 and a driving wheel 7, and an adjusting screw 8 is also provided below the driving wheel 7, and the adjusting screw 8 is to adjust the distance between the driving wheel 7 and the running wheel 9. Make driving wheel 7 and running wheel 9 run on the line and have certain suitable degree of tightness.

[0013] The size and length of the three horizontal shafts 3 connected to the curved cage 1 are the same, and the two ends are provided with wire teeth installation baffles. The connection between the curved cage 1 and the horizontal shaft 3 is movable. The spacing between 11 needs to be adjustable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com