Large-scale multi-angle template allowing one-step cutting

A multi-angle, one-size-fits-all technology, applied in the direction of shearing devices, shearing machine accessories, metal processing equipment, etc., can solve the problems of increasing the cost and operation risks of enterprises or individuals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

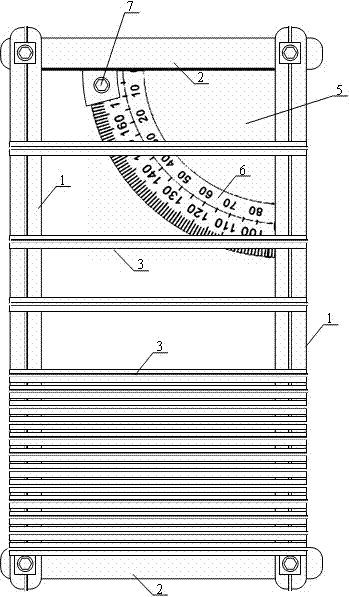

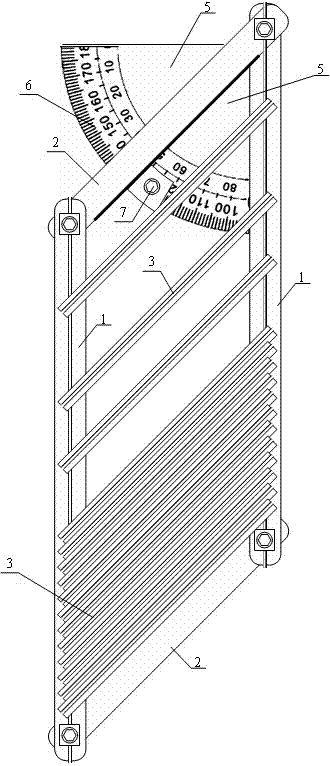

[0015] Such as figure 1 As shown, a large batch of materials need to be cut, and the one-size-fits-all large multi-angle template designed by this scheme is used. The multi-angle template is installed on the cutting bed by three horizontal square steels with two inner grooves on the square steel. Steel 1, inner channel steel 1 is vertically superimposed on the square steel. Two inner channel steels 1 are provided with two angle steels on both ends of the steel. 2 and the inner channel steel 1 are connected to each other by screws to form a rectangular ring, rectangular ring The four corners are movable, and the angle can be changed arbitrarily. The method of change is to keep the inner channel steel 1 on the right side unchanged, and move the inner channel steel 1 on the left back to change the angle.

[0016] An adjustment screw is provided at each end of the inner channel steel 1 of the rectangular ring in the cutting direction and the horizontal steel underneath. The cutting ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com