Pipe body telescopic derrick (rotary pulley)

A telescopic, pole-holding technology, applied in building types, buildings, towers, etc., can solve problems such as difficulty in standing, difficult to reach height, and aggravating enterprise construction costs and operating risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

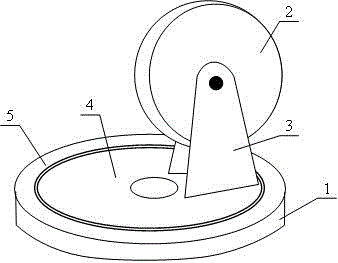

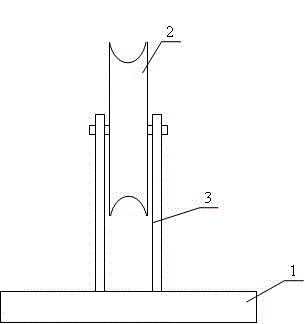

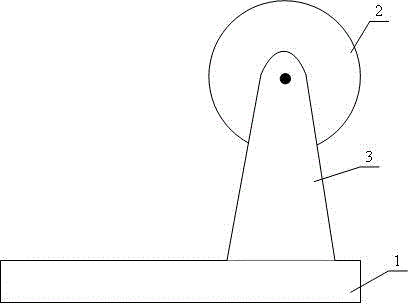

[0009] As shown in the figure, a telescopic tube holding pole (rotary pulley). The rotating pulley is installed on the top 1 of the holding pole. It can maintain the verticality of the steel wire rope of the top 1 of the holding pole. On one side of the bearing inner circle 4, the bearing outer circle 5 is closely matched with the top 1 of the holding rod, and the pulley groove and the center of the holding rod are on a straight line. According to which direction the hanger needs to hold the pole, the rotating pulley will automatically turn to that direction, which can keep the wire rope of the hanger always in the center of the hold pole. The defects of the prior art are solved, the construction is convenient, and the labor force and time are saved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com