Patents

Literature

125results about How to "Solve the problems existing in the known technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Averaging circuit for enhancing channel estimation in receptor and compensating frequency offset residue

ActiveCN1848834ASolve the real problemAccurate Channel Impulse Response EstimatesChannel estimationMulti-frequency code systemsBaseband receiverPhase shifted

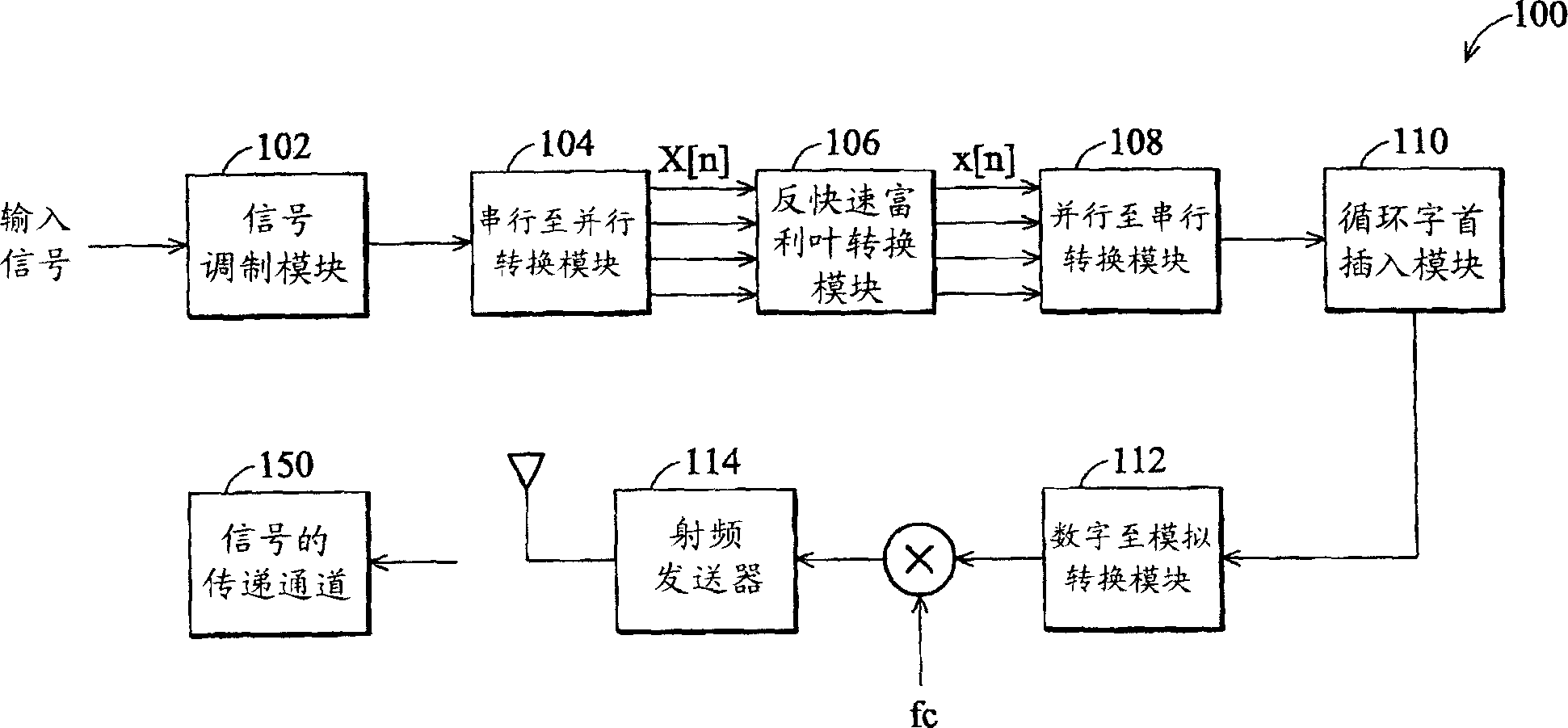

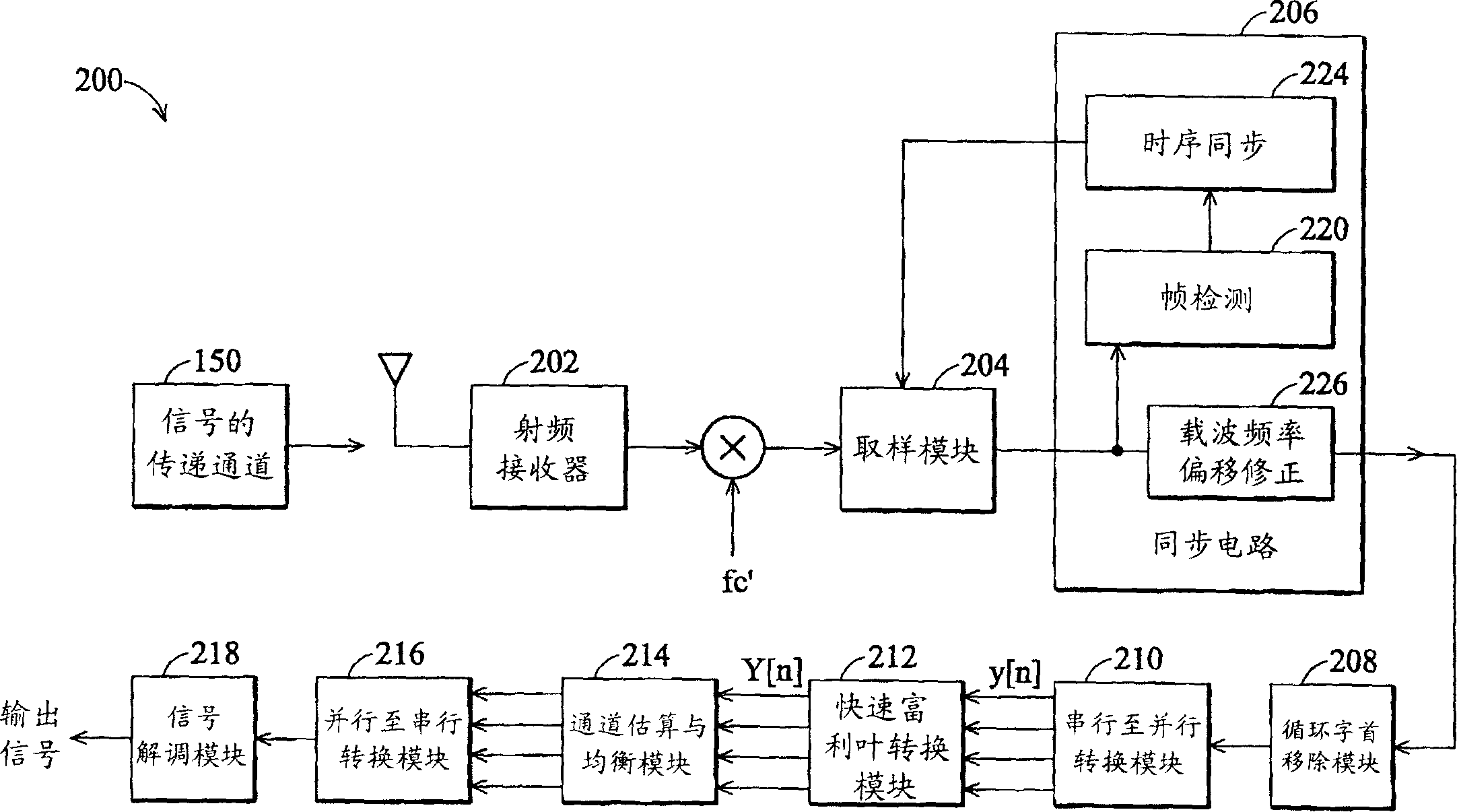

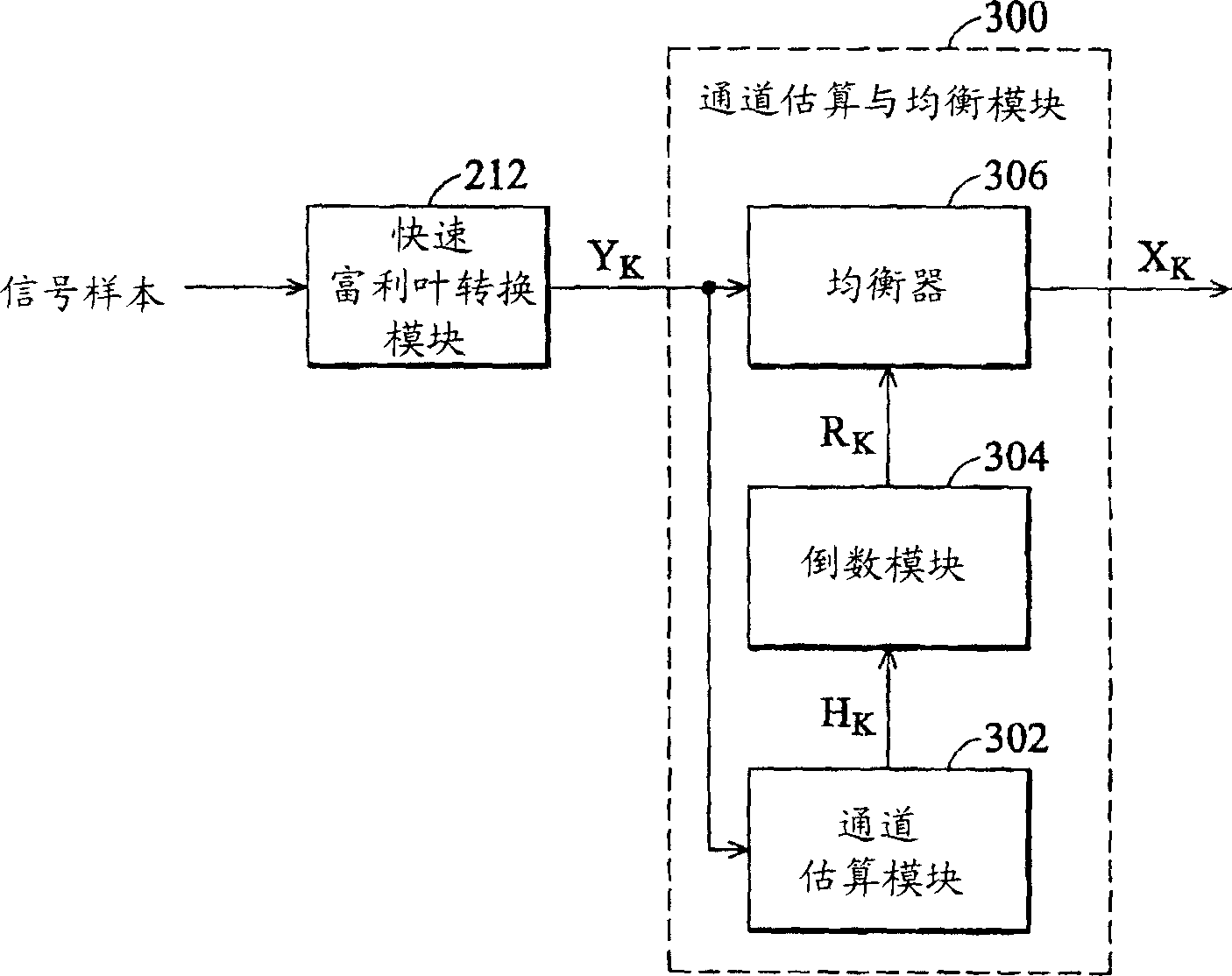

An equalization circuit for an OFDM baseband receiver, comprising: a channel estimation and equalization module for compensating channel distortion of a first signal according to an impulse response to obtain a second signal; a residual frequency offset compensation module, coupled to the channel estimation and equalization module, for estimating the offset phase caused by the residual frequency offset, and compensating the second signal according to the offset phase to obtain a third signal; and an error estimation module, coupled to the residual frequency offset compensation module, for generating an error estimation value according to the third signal and its hard decision estimation value, and feeding back the error estimation value to the channel estimation and equalization module , so that the channel estimation and equalization module corrects the estimated value of the channel impulse response of the first signal at a next time point sample.

Owner:VIA TECH INC

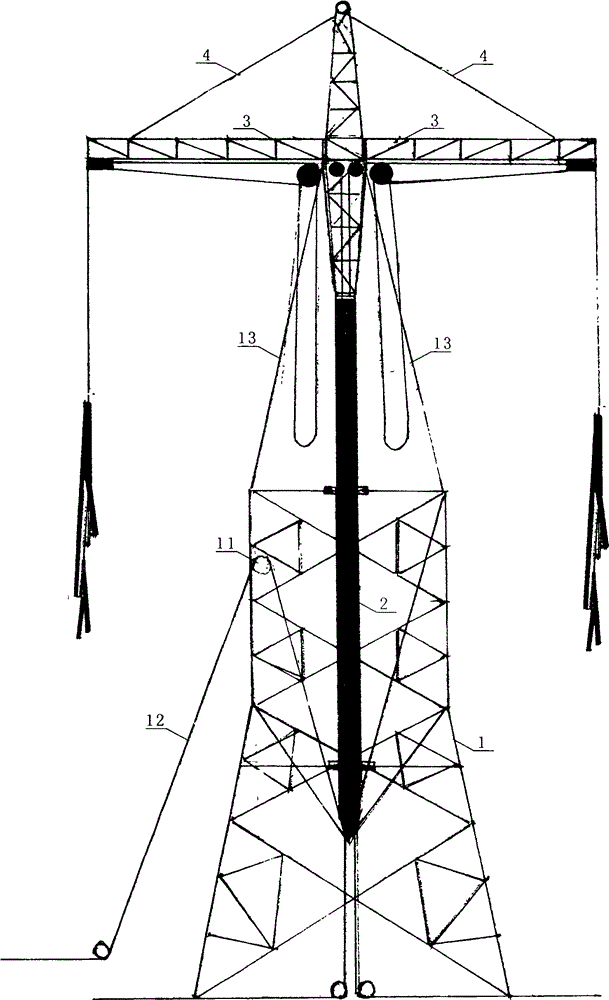

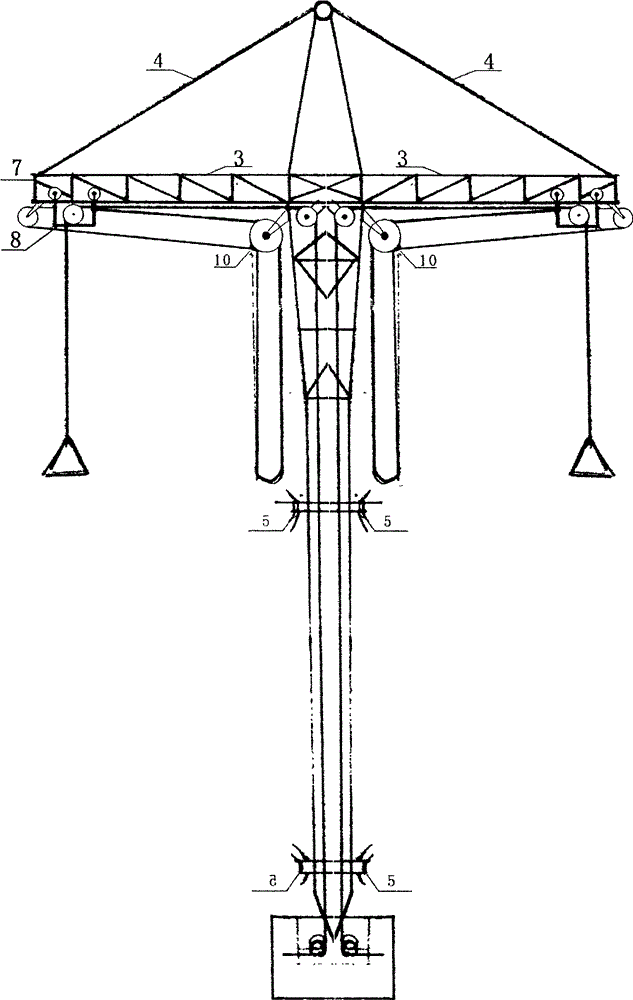

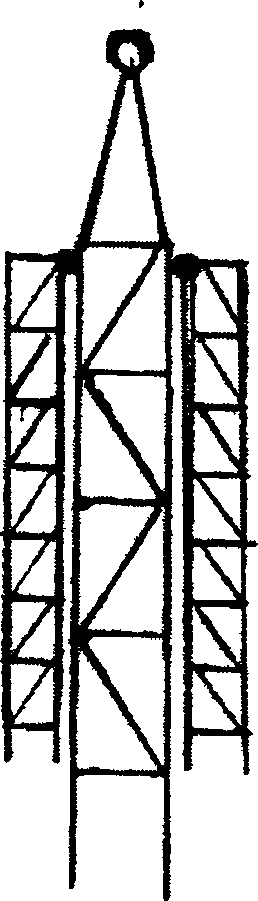

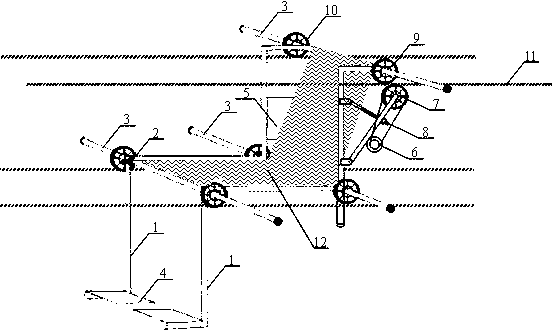

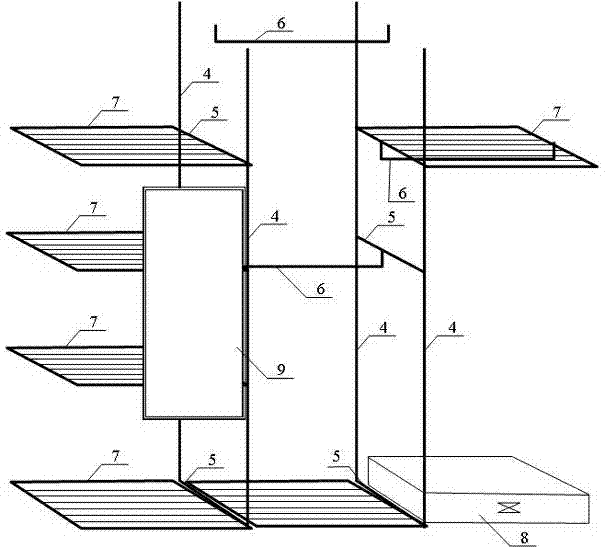

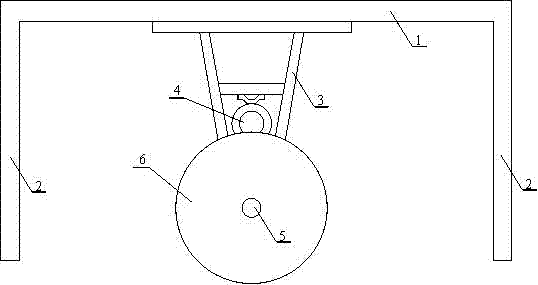

Sphere tower crane type derrick

InactiveCN104153637ASolve the problems existing in the known technologyAchieved goalsTowersArchitectural engineeringTower crane

The invention discloses a sphere tower crane type derrick. The derrick (2) is formed by connecting multiple sections of short derricks, the two sides of the top of the derrick are provided with branch derricks (3) which are perpendicularly connected with the derrick, and guide rails (7) are formed below the branch derricks (3). Two pairs of wheels (9) supporting pulley vehicles (8) at the two sides move in the guide rails (7) under the control of a block (10), a pull rope connected with a winch is contained in a pulley groove in each pulley vehicle for lifting weights, and the derrick is connected with a wire tower under construction through a set of pull ropes including waist hoops (5). The bottom of the derrick is provided with a derrick lifting device. The sphere tower crane type derrick is convenient to use and low in cost.

Owner:唐登巨

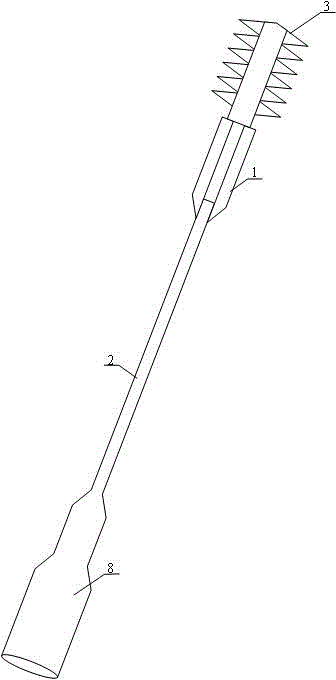

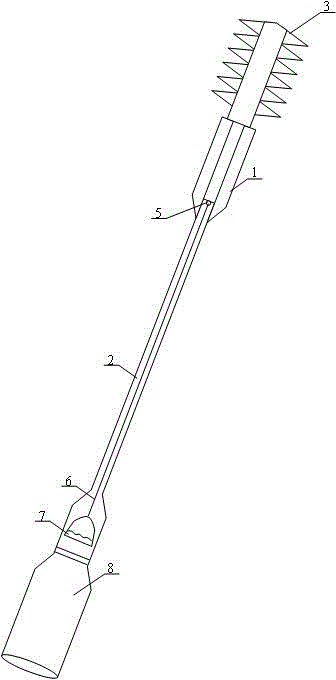

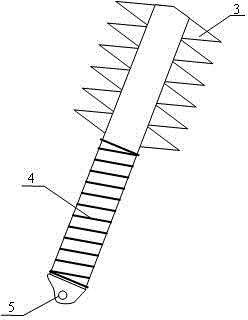

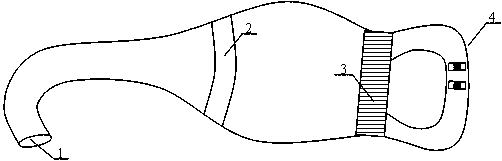

Zanthoxylum bungeanum picking knife

InactiveCN105309123ASolve the problems existing in the known technologyAchieved goalsPicking devicesZanthoxylum bungeanumEngineering

A zanthoxylum bungeanum picking knife comprises a main block and an auxiliary block, wherein the main block is provided with a slide chute (1) connected with the upper end of a hollow cutter bar (2); the middle section of the auxiliary block is located in the slide chute (1) of the main block, cutter teeth (3) are arranged at the upper section and matched with a cutter (3) at the upper section of the main block, a spring (4) is arranged outside the lower section of the auxiliary block, one end of the spring (4) is arranged in a blocking manner on a retainer ring I (5) at the middle section of the auxiliary block, the other end is arranged in a blocking manner on a retainer ring II (5) of the cutter bar (2), the lower end of the auxiliary block is connected with a pull rod (6), and the other end of the pull rod (6) is adjacent to a handle I (7); a handle II (7) is also arranged in the connected position of the cutter bar (2) and an arm sleeve (8) and located in a pipe. When a worker picks zanthoxylum bungeanum, hands extend into the arm sleeve (8) and hold the two handles (7) in the arm sleeve (8), the handles are grasped and loosened alternately, and the zanthoxylum bungeanum can be smoothly picked off through continuous grasping and loosening; the zanthoxylum bungeanum picking knife is used randomly, and the hands cannot be stabbed by zanthoxylum bungeanum thorns.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

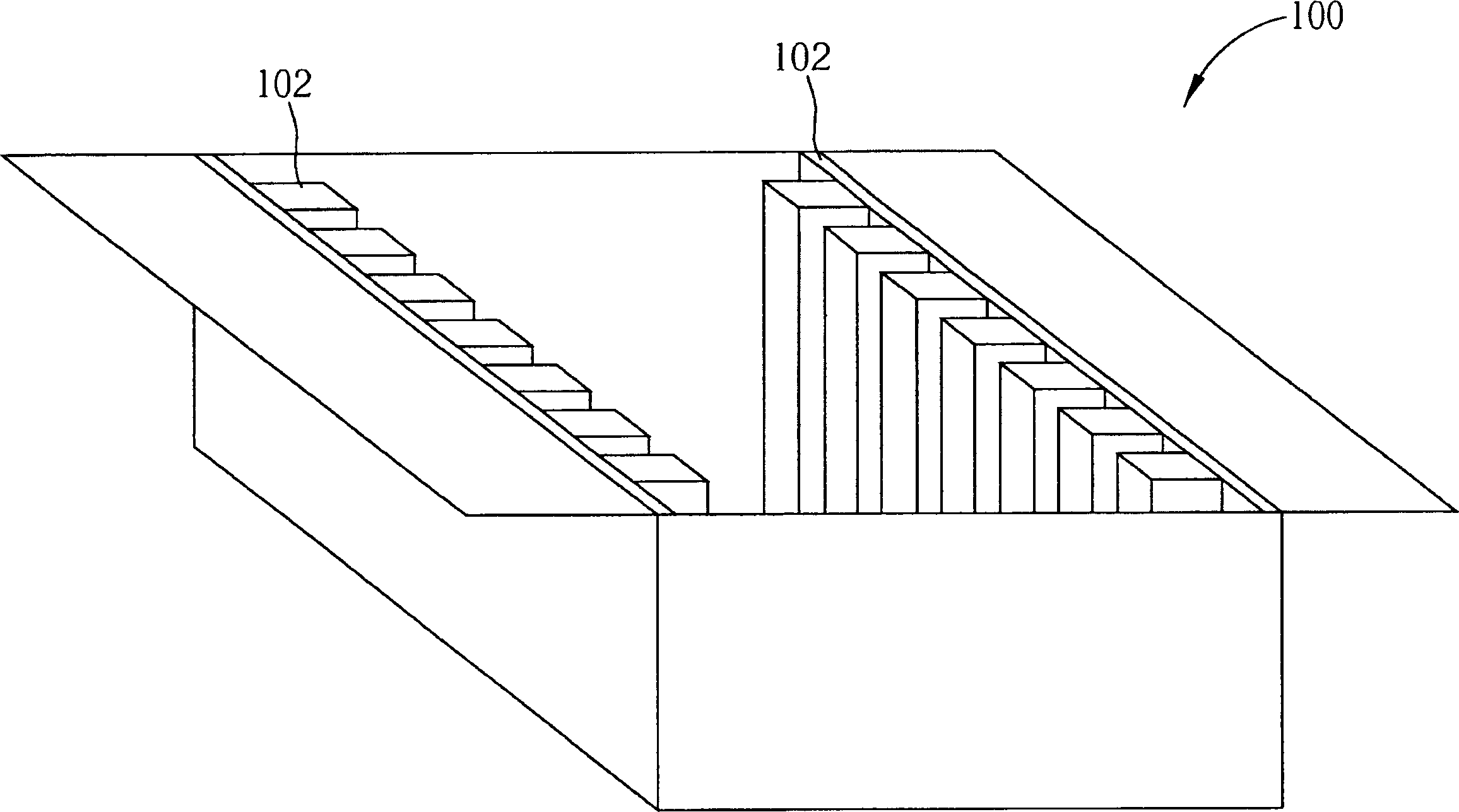

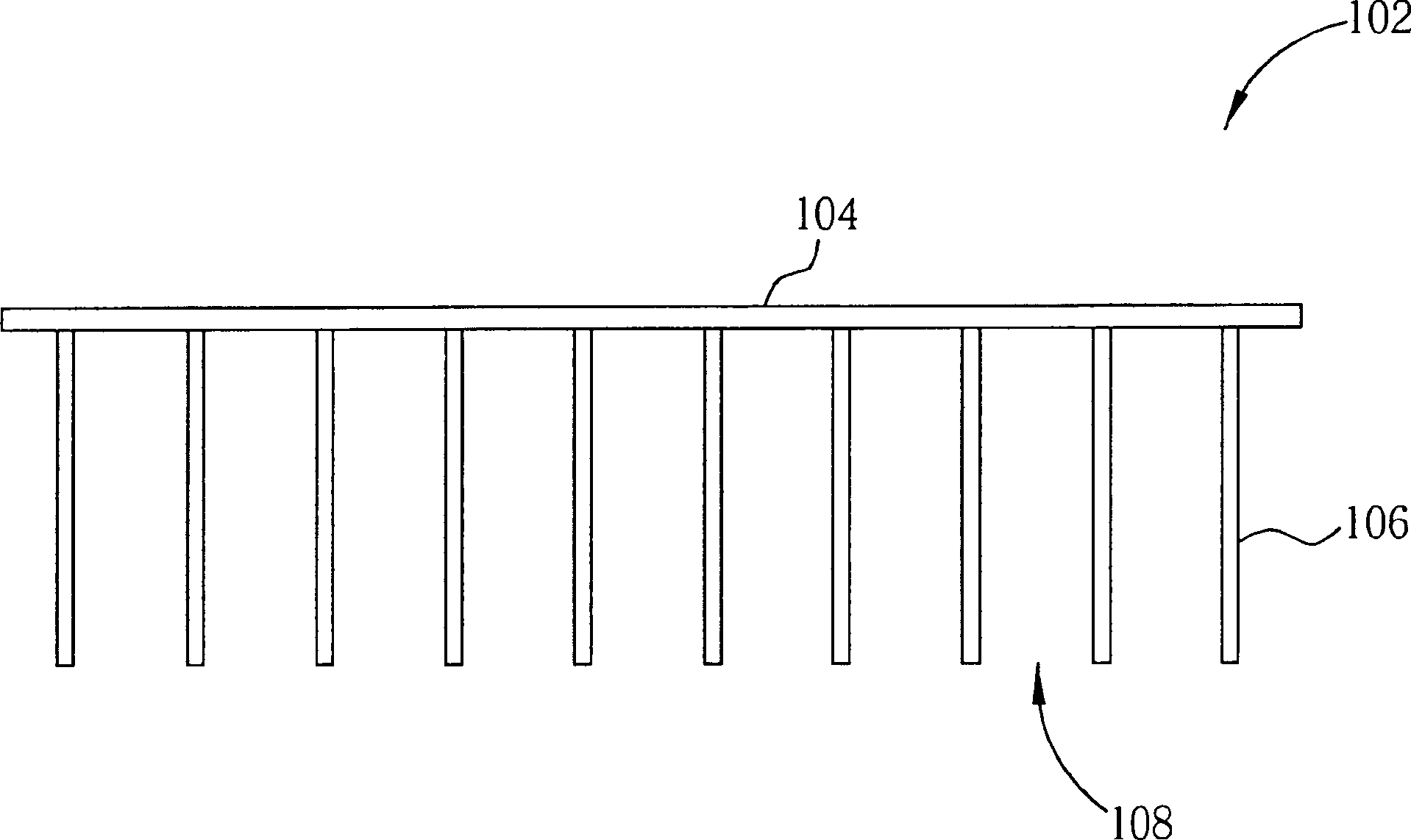

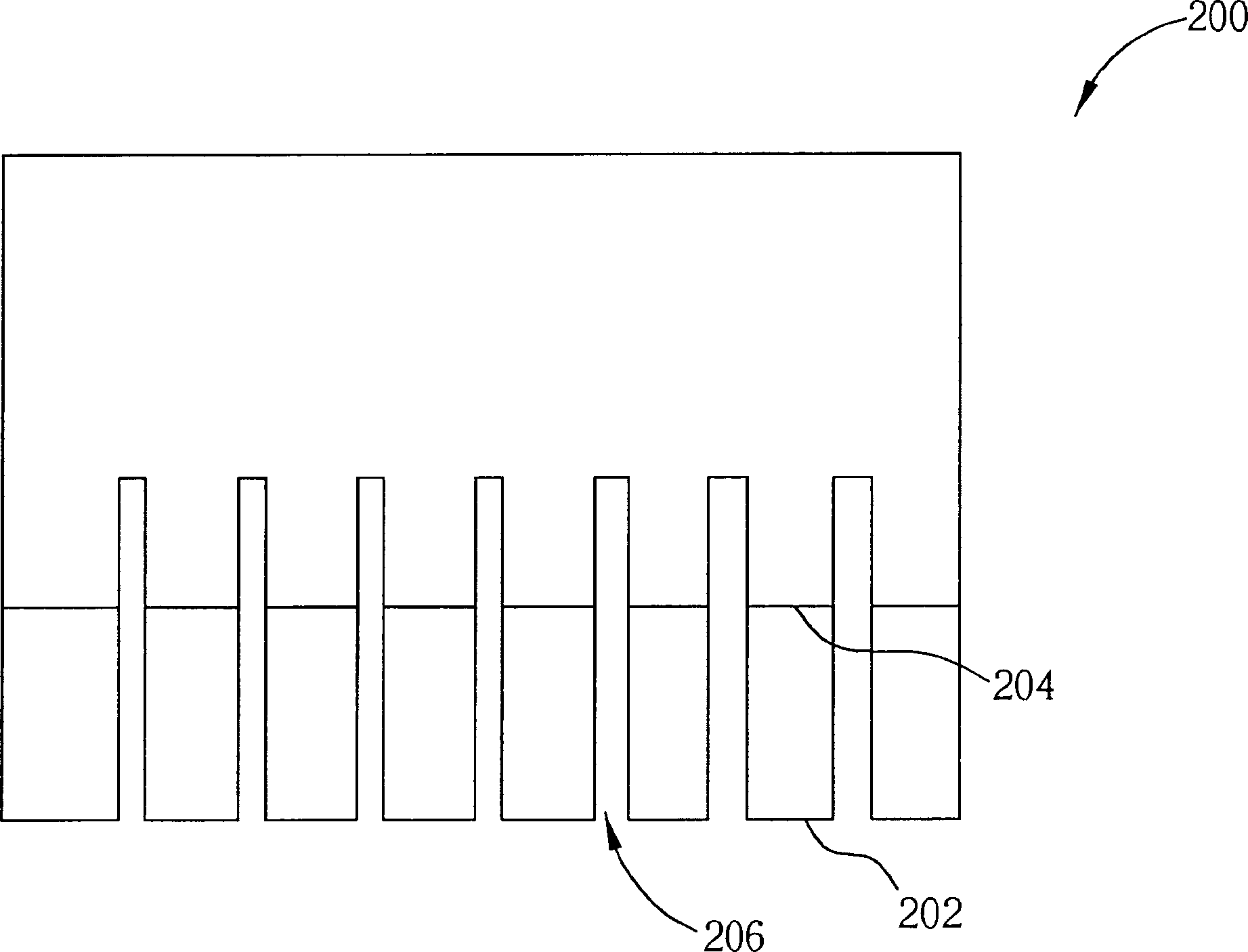

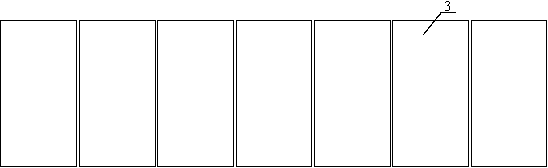

Partition structure for buffering package material

InactiveCN1587003ASolve the problems existing in the known technologyImprove convenienceExternal framesMechanical engineeringEngineering

Owner:AU OPTRONICS CORP

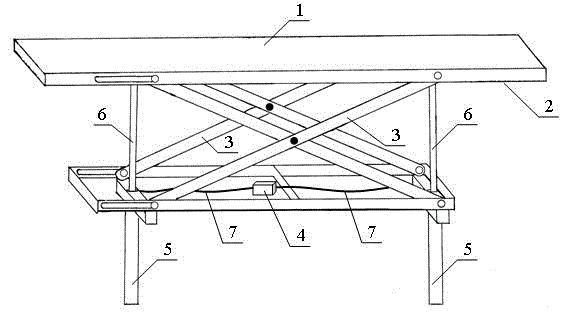

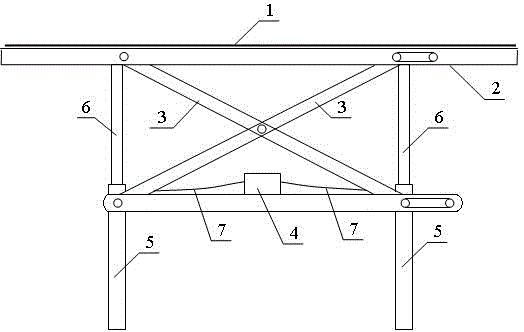

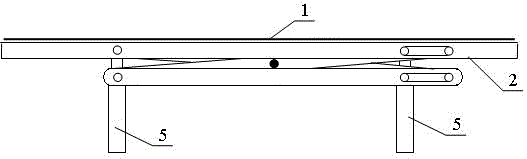

Vehicle sleeping platform (scissors form)

InactiveCN104891384ASolve the problems existing in the known technologyAchieved goalsLifting framesHydraulic cylinderMarine engineering

The invention discloses a v ehicle sleeping platform (scissors form). A platform surface (1) of the vehicle sleeping platform is designed as a steel plate platform surface (1) with a length and a width exceeding that of a truck, and is leveled with the ground; a reinforcing device (2) is arranged below the platform surface (1), and is welded with the platform surface (1); a scissors type lifting device (3) is arranged below the reinforcing device (2); a hydropress (4) is arranged below the middle of the scissors type lifting device (3); a hydraulic cylinder (5) and a hydraulic rod (6) are arranged at the two ends of the scissors type lifting device (3); and one end of a hydraulic pipe (7) is connected with the hydropress (4), and the other end is connected with the hydraulic cylinder (5). The lifting device of the vehicle sleeping platform fits the support force of the hydraulic device to finish the lifting of the vehicle sleeping platform, so that the construction is convenient, and the construction cost and time are saved.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

Garbage collection vehicle

InactiveCN103803225ASolve the problems existing in the known technologyAchieved goalsRefuse vehiclesRefuse collectionWaste collection

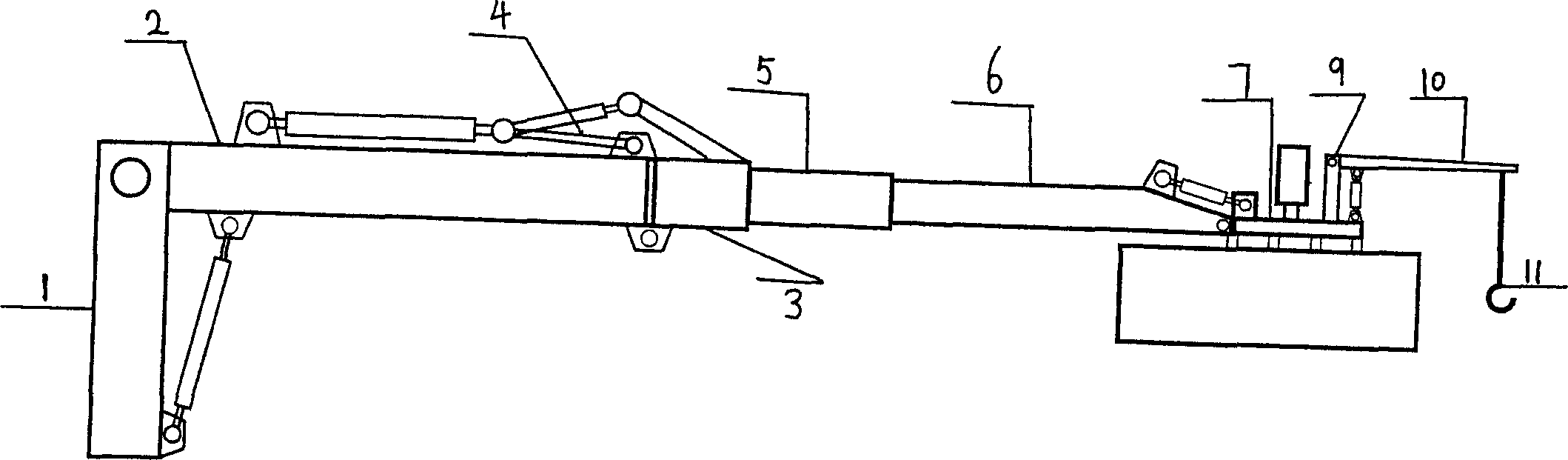

The invention provides a garbage collection vehicle. A mechanical arm is mounted on the vehicle, and comprises a mechanical arm seat, a central vertical shaft, a mechanical large arm, a mechanical middle arm, a mechanical small arm, a middle arm sleeve, a connecting ring rod, a connecting plate, a digging pliers hopper and a hook, wherein a hydraulic control is arranged on each movable part of the mechanical arm, and the mechanical arm can stretch and contract and can move upwards and downwards as well as leftwards and rightwards by the hydraulic control; a closed garbage can comprises a can body, a central vertical shaft, a can cover, a movable cover, a can bottom and a can seat; the garbage can is hung and placed in an inlet of the garbage collection vehicle by the garbage collection vehicle; garbage in the garbage can is automatically dumped in a carriage by a garbage dumping device on the vehicle under the pressure of the can.

Owner:唐登巨 +1

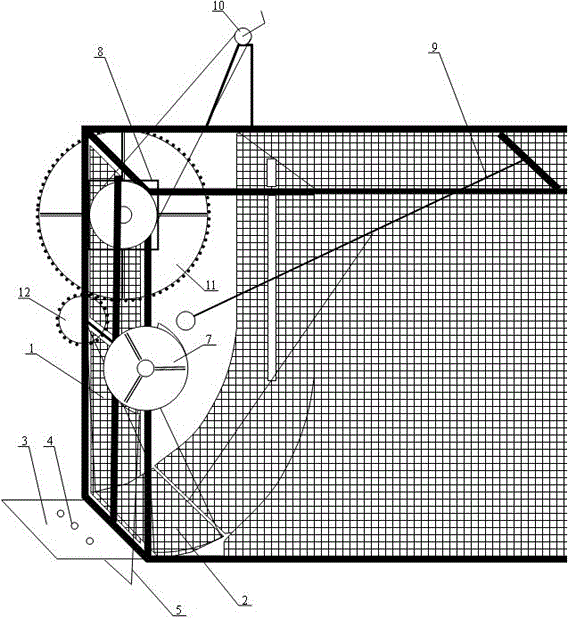

A net cage allowing fishes to enter and preventing fishes to leave

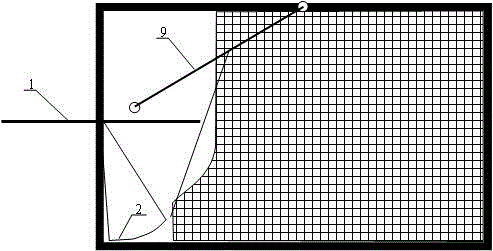

ActiveCN106804542ASolve the problems existing in the known technologyAchieved goalsFishingEngineering

The invention provides a net cage allowing fishes to enter and preventing fishes to leave. The left front portion of a frame of the net cage is provided with a rotary automatic closing door (1) and a gate (2); a platform (3) is arranged before the doors; a row of holes are formed in the platform (3); hooks (4) are arranged on the tops of the holes and a trap rod (5) is installed under the holes; a trap (6) is installed on the upper end of an angle support of the trap rod (5); the trap (6) is the switch for the rotary automatic closing door (1); the rotary automatic closing door (1) includes two oppositely connected plates. When bait is not touched by fishes, the door (1) is closed vertically; the right end of a central shaft of the door (1) is provided with a toothed disc (7) to which the trap (6) is clamped; once the bait is touched by fishes, the trap (6) jumps out of a disc tooth and is clamped to another disc tooth; every time the bait is touched by fishes, the disc tooth to which the trap (6) is clamped changes once; the gate (2) is installed on the left front and is closed when there is no movement; the gate is driven by rotating force generated when the door (1) rotates to drive fishes into the cage.

Owner:吴川市鸿海绳网制造有限公司

Aluminum type environmentally-friendly chest

InactiveCN104510182ASolve the problems existing in the known technologyAchieved goalsWardrobesRigid cabinetsEnvironmental resistanceMaterials science

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

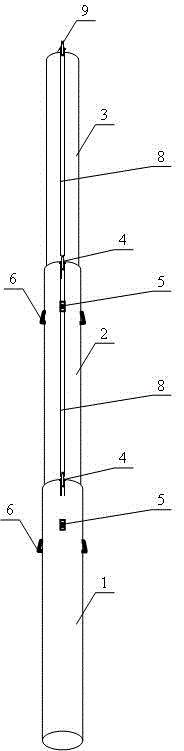

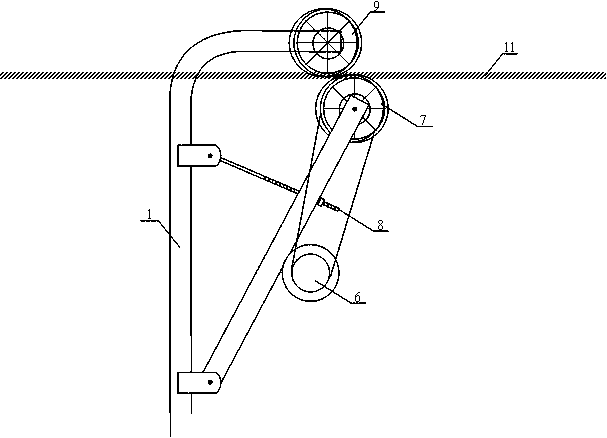

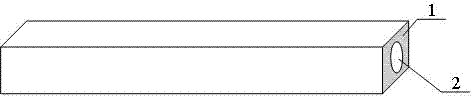

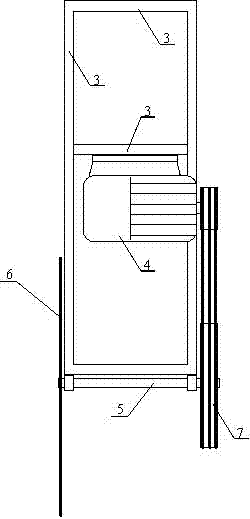

Pipe body telescopic holding pole

InactiveCN106285173ASolve the problems existing in the known technologyAchieved goalsTowersEngineeringPulley

The invention discloses a pipe body telescopic holding pole comprising three seamless steel pipes of different sizes and sleeved in an inner-middle-outer manner; a telescoping wire rope pulley (4) is arranged by the top of the outer holding pole (1); a locking bolt (5) is arranged in a position 1m below the pulley (4); a holding pole self-joint outer valve (6) is arranged below the locking bolt (5); the bottom of the middle holding pole (2) is provided with a self-joint inner valve (7); a groove (8) receiving a telescoping wire rope is arranged on the middle holding pole (2) from top to bottom; the groove (8) and the locking bolt (5) can provide guiding positioning purpose; the middle holding pole (2) is 1m longer than the outer holding pole (1), and the prolonged 1m pole is designed to be the same with the 1m segment above the outer holding pole (2); a self-joint inner valve and a groove (8) of the inner holding pole (3) are designed to be the same with that of the middle holding pole (2); the top of the inner holding pole (3) is provided with a hanger wire rope pulley (9) having a 360-degree automatic turning function.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

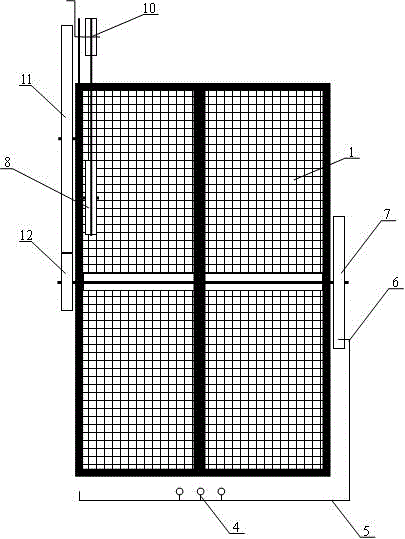

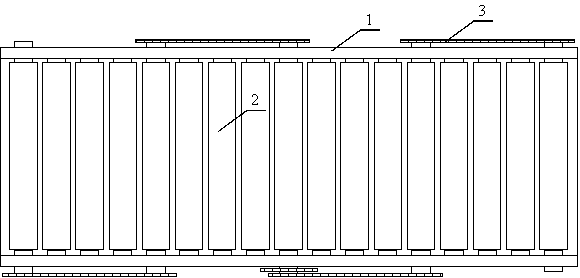

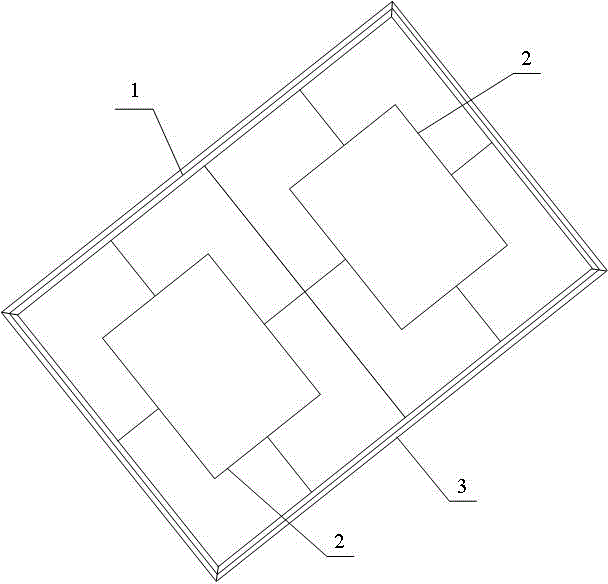

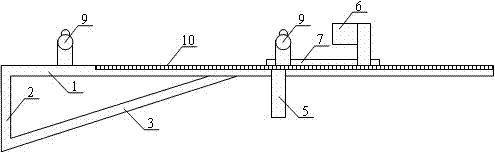

Workshop pallet

InactiveCN108657837ASolve the problems existing in the known technologyAchieved goalsLoading/unloadingButt jointEngineering

The invention discloses a workshop pallet. The workshop pallet is a workshop pallet which is arranged between a workshop and a forklift passage or between transfer pallets and is used in a cooperatingmode together with workshop or the transfer pallets through a series of loading and unloading equipment; and the workshop pallet is a starting point pallet and is used for enabling goods which are achieved a whole state from a scattered state to slide to an abutting port of the forklift passage from the workshop so as to achieve butt joint with a loading and unloading pallet of a forklift and toachieve butt joint with the transfer pallets in a sliding conveying mode. The workshop pallet is characterized in that a rectangular framework (1) is mounted between the workshop and the forklift passage, a part of the framework (1) is arranged in a workshop wall body, a part is arranged outside the wall body, the framework (1) is internally provided with dozens of rollers (2), one roller of everythree rollers is provided with a shaft in the center and is provided with chain gears and chain (3) at the two ends, the chains and the chain gears (3) are arranged outside the framework (1), a motor(4) is arranged below the framework (1), a gearbox (5) drives the third one of the rollers (2), the third roller drives the fourth roller, and the third roller drives the second roller and the firstroller in the opposite direction.

Owner:岳池巨力创新科技有限公司

Special internal angle steel for aluminum type environmentally-friendly chest

InactiveCN104510185ASolve the problems existing in the known technologyAchieved goalsWardrobesFurniture partsEnvironmentally friendlyEnvironmental resistance

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

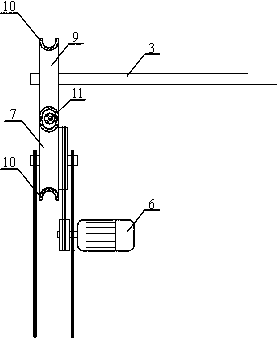

Electric chair on wire

InactiveCN108155597ASolve the problems existing in the known technologyAchieved goalsApparatus for overhead lines/cablesDrive wheelUpper segment

The invention discloses an electric chair on a wire. A light and thin steel pipe is adopted to make two bending-type protection frames (1). Bending portions are provided with hoops (2) which are movably connected to transverse shafts (3). Lower segments are provided with foot pedals (4). The left side of upper segments is provided with a cell box (5). The right side of one bending-type protectionframe is provided with a motor (6) and a driving wheel (7). An adjusting screw rod (8) is arranged below the driving wheel (7). The three transverse shafts (3) connected to the bending-type protectionframes (1) are consistent in size and length. The two ends of each transverse shaft are provided with running wheels (9). The centers of the running wheels (9) are provided with bearings. The bearings and the transverse shafts (3) are tightly cooperated and can be adjusted. The outer edges of the running wheels (9) are provided with tyres (10). The inner ring type of the tyres (10) matches with wheel rims. Outer ring grooves are designed according to various models of sleeve wires (11). A cushion (12) is made of canvas and is provided with three passing cylinders.

Owner:岳池巨力创新科技有限公司

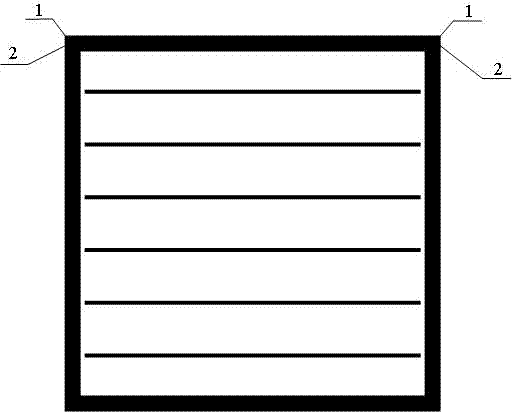

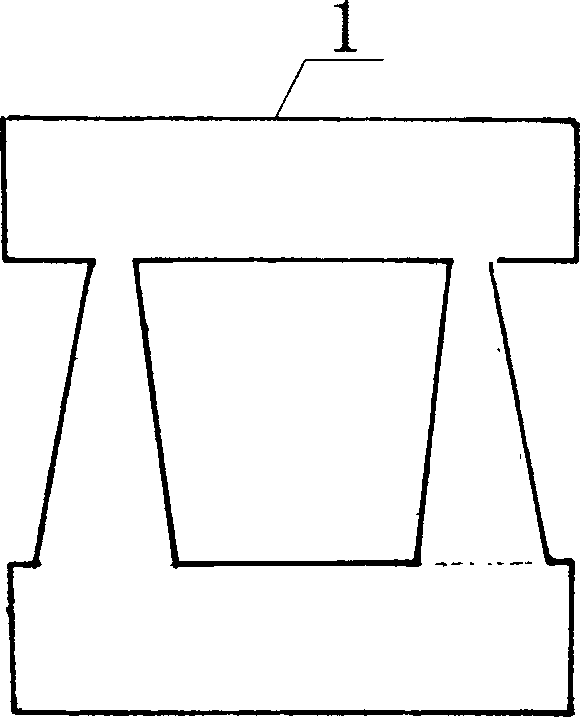

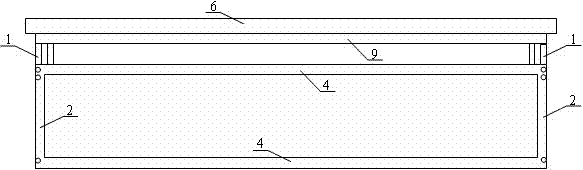

Fixedly-pasting formwork (formwork frame)

InactiveCN104831914ASolve the problems existing in the known technologyAchieved goalsBuilding constructionsSquare ShapeNail plate

The invention discloses a fixedly-pasting formwork (a formwork frame). The formwork frame is made of plastic steel instead of angle iron. A frame (1) of the formwork frame is in a right-angle square shape, and lining strips (2) are arranged in the center of the frame (1) of the formwork frame. Abrasion resisting strips (3) are arranged on an upper opening of the frame (1) of the formwork frame. The inner diameter of the formwork frame is larger than the length of a formwork nail plate by 6 mm and larger than the width of the formwork nail plate by 6 mm. Due to the fact that mortar joints are arranged on the left side and below the formwork, the mortar joints are connecting mortar joints of pasted tiles and tiles to be pasted, the formwork frame is used in cooperation with the formwork nail plate, and the thickness of mortar of each ceramic tile on the formwork nail plate, the flatness and balanced edge mortar of each tile can be supported and grasped through the formwork frame.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

Sealing nut

InactiveCN104514795ASolve the problems existing in the known technologyAchieved goalsNutsEngineeringFastener

The invention discloses a sealing nut specially for fastening framework joint structure of environment-friendly cloth wardrobe; the sealing nut comprises a steel sheet (1) which is standardly punched into the same size as the inner diameter of the square pipe; the steel sheet (1) is provided with a central hole of a female screw (2); the steel sheets (1) are firmly sealed at two ends of the square pipe by welding; four outer posts and four cross beams are inserted into inner posts inside insertion section fasteners; the short cross beams, the clothes hanging rods, and the clothes placement racks are all provided with the sealing nuts (2); the sealing nuts (2) of the clothes hanging rods are round.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

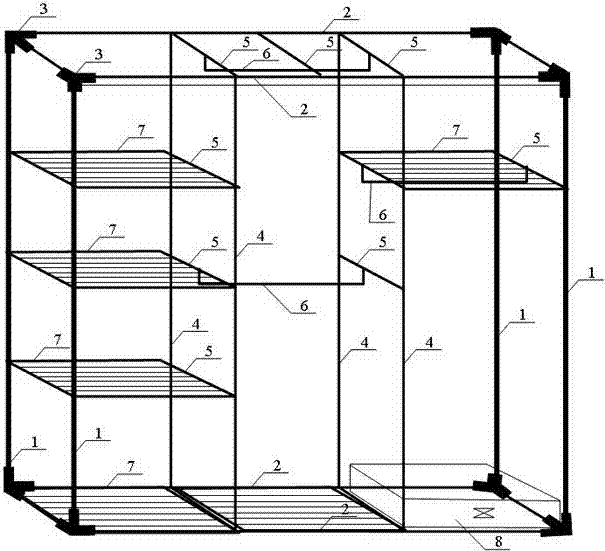

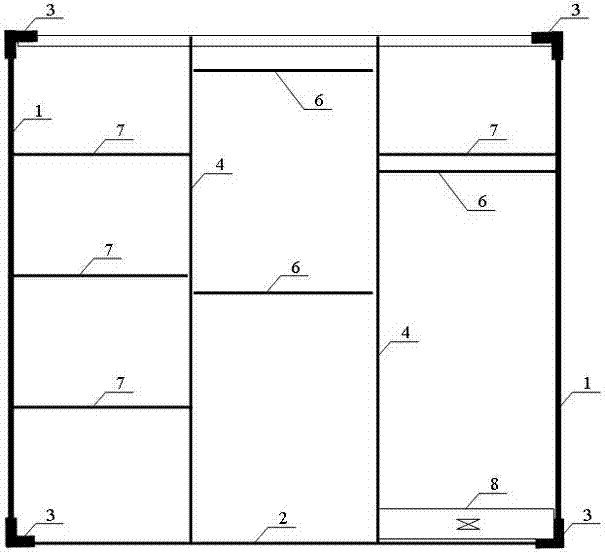

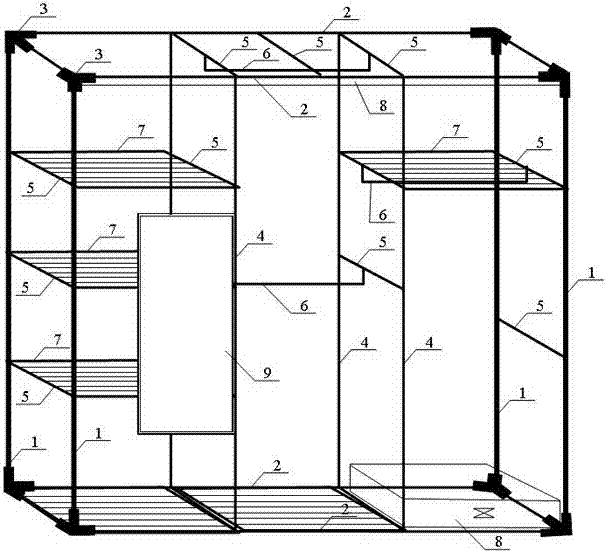

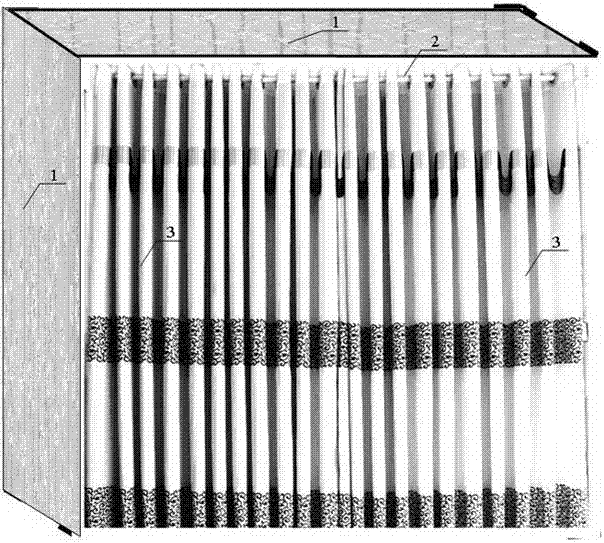

Cloth environment-friendly wardrobe

InactiveCN104510184ASolve the problems existing in the known technologyAchieved goalsWardrobesDismountable cabinetsEngineeringBedroom

The invention discloses a cloth environment-friendly wardrobe. According to the wardrobe, a framework is made of stainless steel square tubes; insertion section buckles (3) are arranged on four sides and eight corners of the framework; four outer columns (1) and four cross beams (2) are inserted into the insertion section buckles (3) to form a hexahedron; two or three eyelets are drilled in the middle sections of the four outer columns (1) respectively; two eyelets are drilled in middle sections of the four cross beams (2) respectively; the two ends of each of inner columns (4) and short cross beams (5) in the middle of the wardrobe are both provided with nut screws; the inner columns (4) and the cross beams (2) are connected and fastened by screws; the short cross beams (5) and the outer columns (1) are also connected and fastened by the screws. Clothes rails are arranged in the middle; the height and the width of the wardrobe are fixed (apart from super-large and ultrahigh wardrobes); the size of the wardrobe is required to be determined by a user according to the size of a bedroom of the user; any size is available; then the framework is covered by a beautiful cover.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

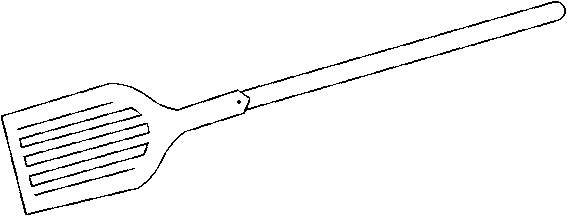

Mud soaking shovel

InactiveCN108142005ASolve the problems existing in the known technologyAchieved goalsSpadesShovelsLeaking waterEngineering

The invention discloses a mud soaking shovel. The mud soaking shovel is a shovel capable of allowing mud to be not adhered to a tool during construction-operation mud soaking and leaking water. The mud soaking shovel is punched with a prototype steel plate, the shovel surface is designed to be in a strip-lattice shape, and a shovel opening comprises a square opening and a circular opening.

Owner:伍莹

Wardrobe door curtain hanging rod seat alternate design style

InactiveCN104510201ASolve the problems existing in the known technologyAchieved goalsCurtain suspension devicesFurniture partsEngineeringMechanical engineering

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

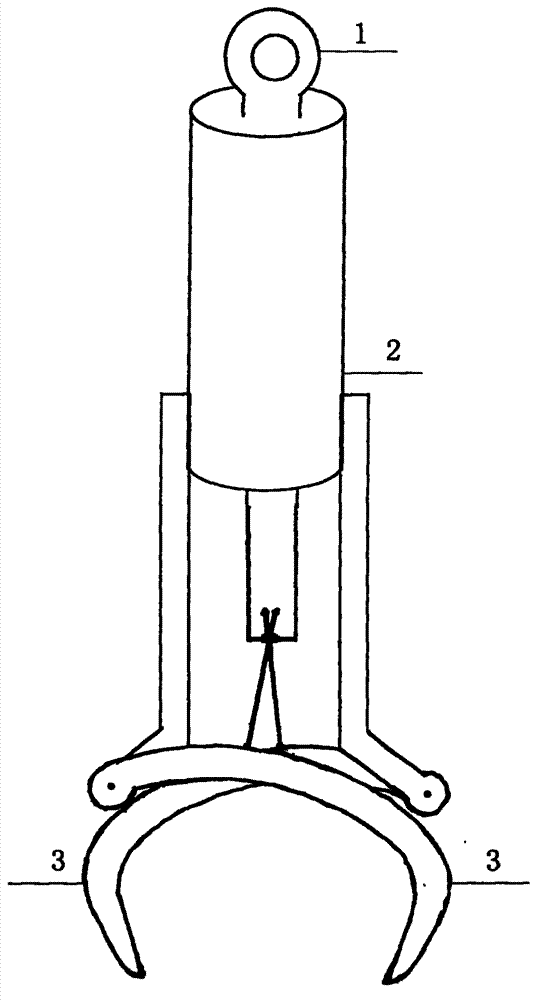

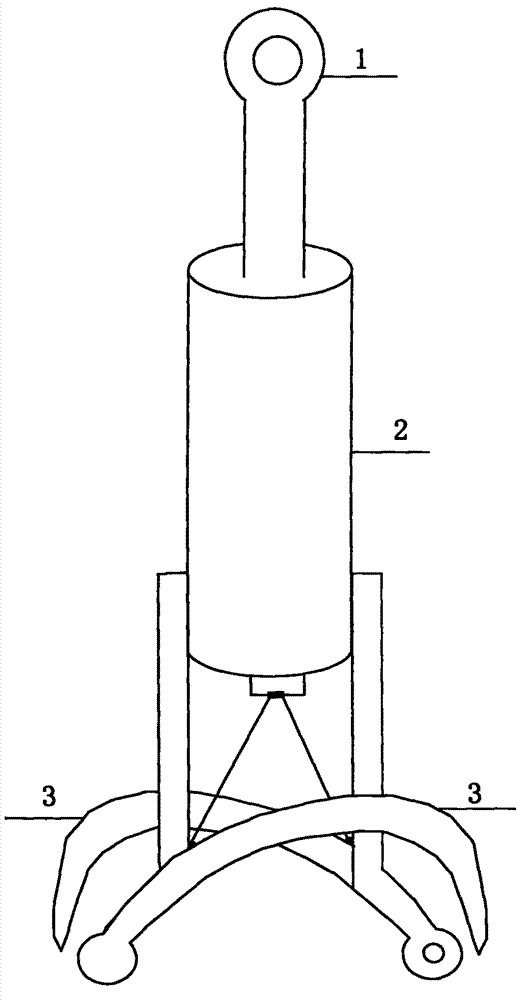

Tiger claw

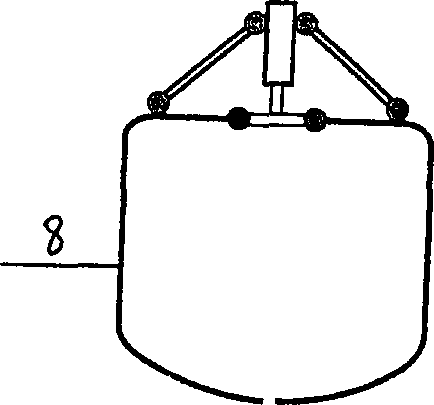

InactiveCN103922221ASolve the problems existing in the known technologyAchieved goalsLoad-engaging elementsEngineeringClutch

The upper end of a center vertical shaft of a tiger claw is tied to a suspension-centre rope of an air lift. No matter steel is hung to ground from a vehicle or hung to a vehicle from ground, a clutch enables the tiger claw to grasp steel once the tiger claw is put on steel bundles and the air lift declines by 0.20 meter, and when steel is hung to an assigned site, the clutch enables two tiger-clawing mechanisms of the tiger claw to be divorced from steel once the air lift declines by 0.20 meter, and thus the construction need is satisfied.

Owner:唐登巨

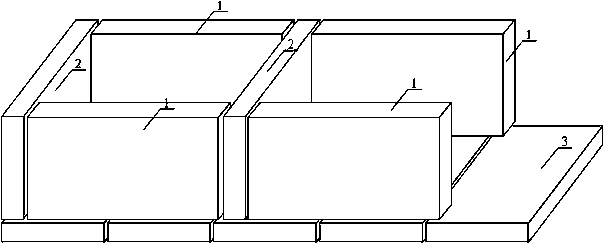

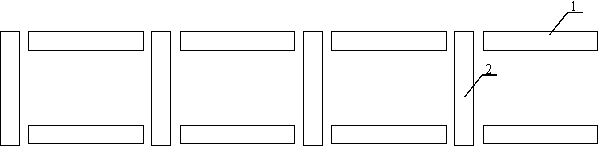

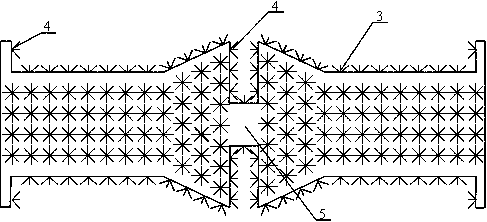

Hollow brick wall construction mode

InactiveCN108130960ASolve the problems existing in the known technologyAchieved goalsWallsSolid wallBrick

The invention discloses a hollow brick wall construction mode. A hollow brick wall aims to reduce the weight of a solid wall by two times or more, and the thickness of the wall can be various, for example, a wall body can be 21 cm or 19 cm or 18 cm thick. Bricks are newly designed. If the wall body is 21 cm thick, two vertical bricks (1) are vertically laid on the two sides of the wall body respectively, then a cavity closing brick (2) is laid, then a cavity is formed, the cavities are laid one by one, a second row of cavity covering bricks (3) are laid after the first row of the wall body isbuilt, the cavity covering bricks (3) are horizontally laid one by one, and the next row and the previous row are identical in building method. If the wall body is larger than 10 cm, the vertical bricks (1) are arranged staggeredely, the cavity closing bricks (2) are laid obliquely, and the cavity covering bricks (3) in the next row are not horizontally laid, are laid in the same way as the previous row and obliquely arranged crosswise. The hollow brick wall has heat insulation and sound insulation functions.

Owner:岳池县福源创新科技有限公司

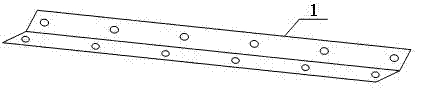

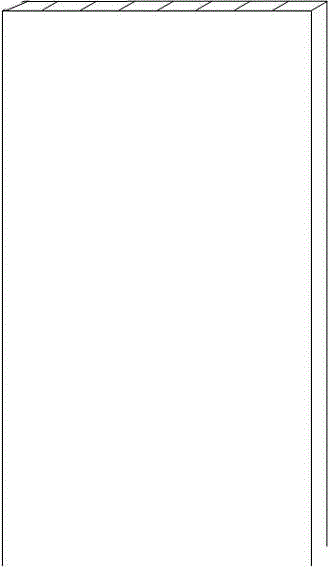

Horizontal vertical hanger

InactiveCN104510186ASolve the problems existing in the known technologyAchieved goalsWardrobesRigid cabinetsEngineeringStructural engineering

The invention discloses a horizontal vertical hanger of a fabric type environmentally-friendly chest. The horizontal vertical hanger is formed by welding square stainless steel pipes, and the square stainless steel pipes are welded to form a lattice type square; opening sealing steel plates (1) are welded at two heads of the square pipe at one side edge off the square; holes are formed in the opening sealing steel plates (1) to store movable connecting screw caps (2), wherein the connecting screw caps (2) are elongated and circular and are inserted into the holes in the centers of the opening sealing steel plates, so as to enable the horizontal vertical hanger to be movably horizontal and vertical.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

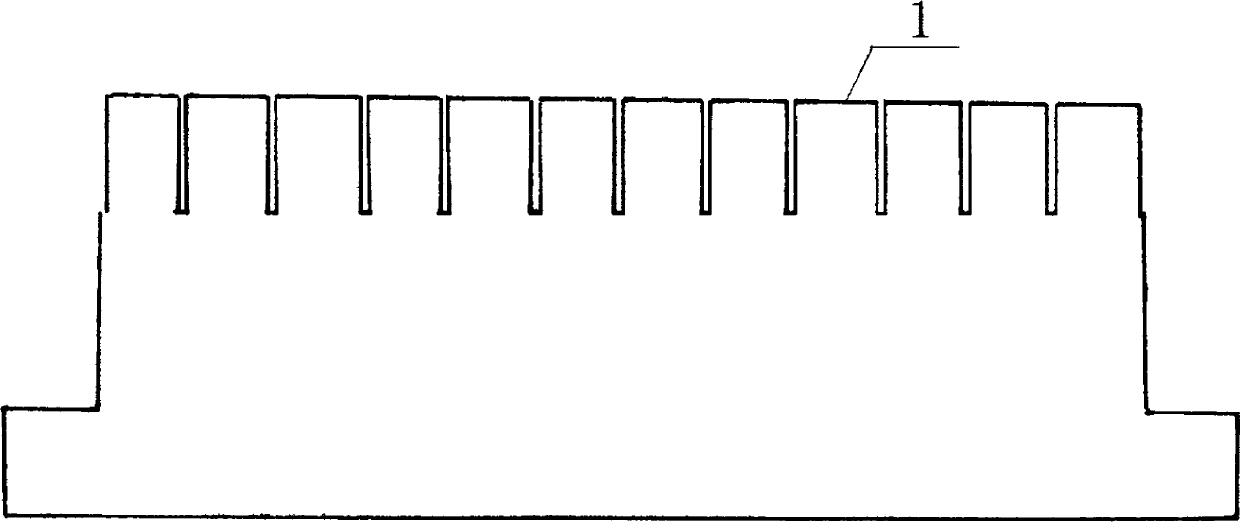

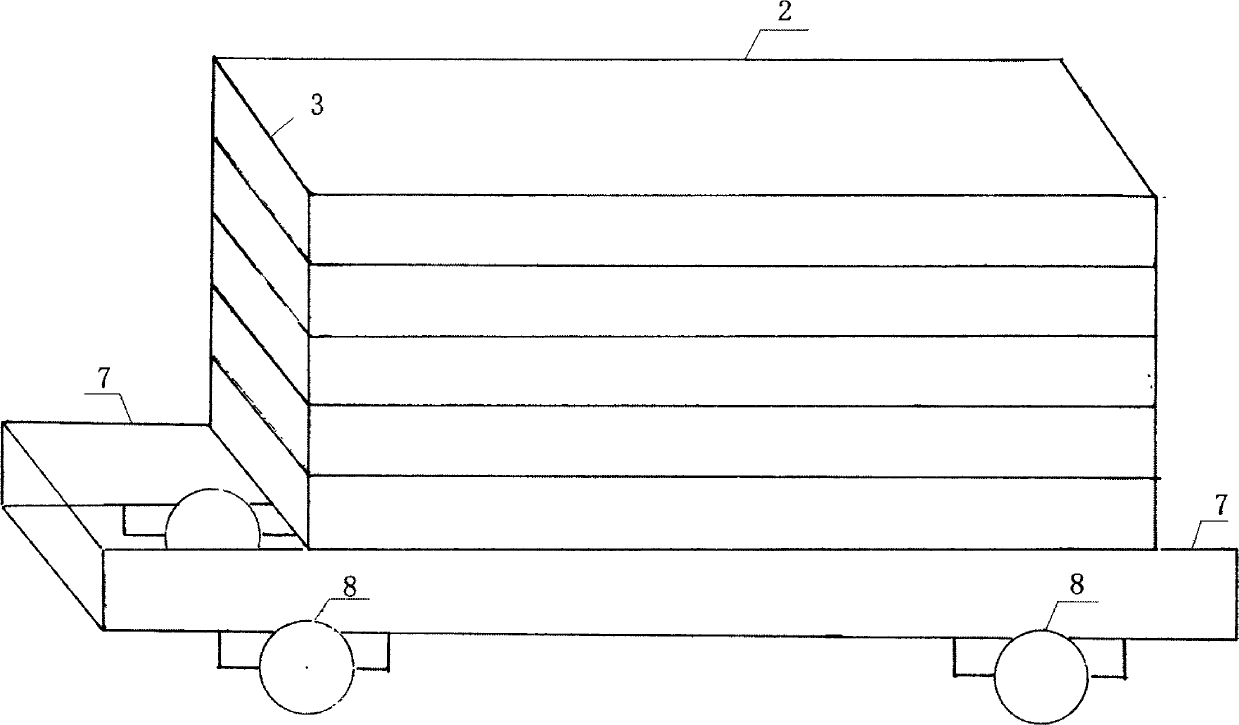

Green brick forming machine

InactiveCN104149164ASolve the problems existing in the known technologyAchieved goalsMouldsBrickMachine design

The invention discloses a green brick forming machine, and green brick production is conducted with the help of the green brick forming machine designed according to the scheme. The green brick forming machine comprises a rectangular green brick box, wherein the rectangular green brick box is composed of twenty bottom plates (1) and twenty square wall plates (2) and (3) and is 4.66 meters in length, 0.7 meter in width and 0.58 meter in height. The green brick box can contain 1200 green bricks. The green brick box wall plates include long square wall plates (2) and short square wall plates (3), and each short square wall plate is provided with a hang buckle (4), a lock pin (5) and a box body positioning screw (6). The width of the wall plates is 5 mm less than that of green bricks (5 mm serves as a saw line), and intervals among the wall plates are kept with the help of a strengthening device. The green brick box is combined and can be detached, roll balls are arranged on a green brick box frame (7), the green brick box bottom plates (1) can slide on the roll balls, four wheels (8) are arranged below the green brick box frame (7) and the wheels slide on a rail, fixing and strengthening devices are arranged on the two sides of the green brick box, a compressor is arranged on the green brick box, the green brick box is filled with powder materials, the powder materials are tightly pressed, then flat sawing, vertical sawing and transverse sawing are conducted through a green brick sawing machine and finished green bricks are formed, so that a large quantity of power resources and manpower resources are saved.

Owner:唐登巨

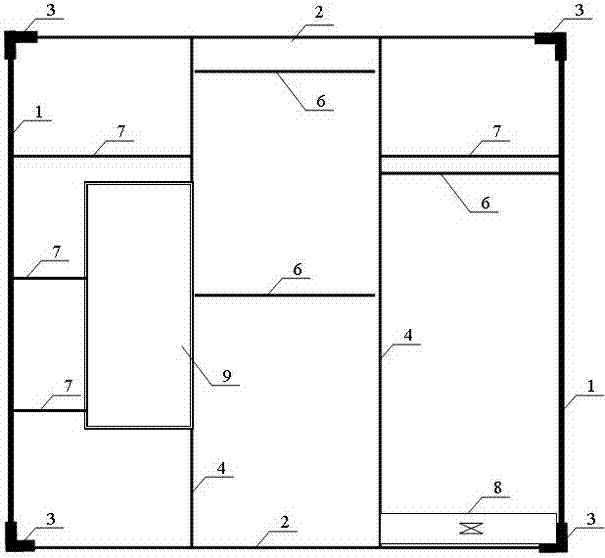

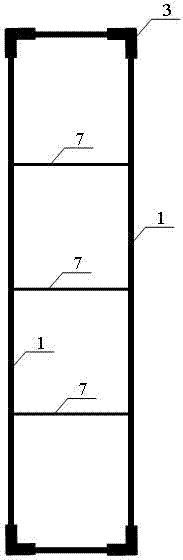

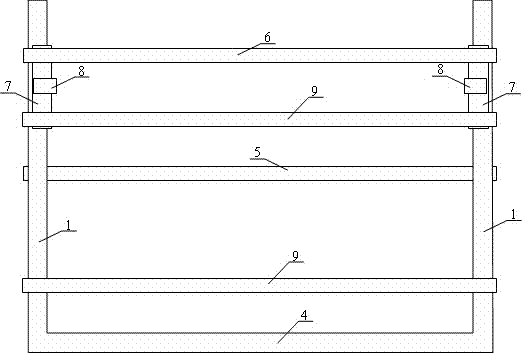

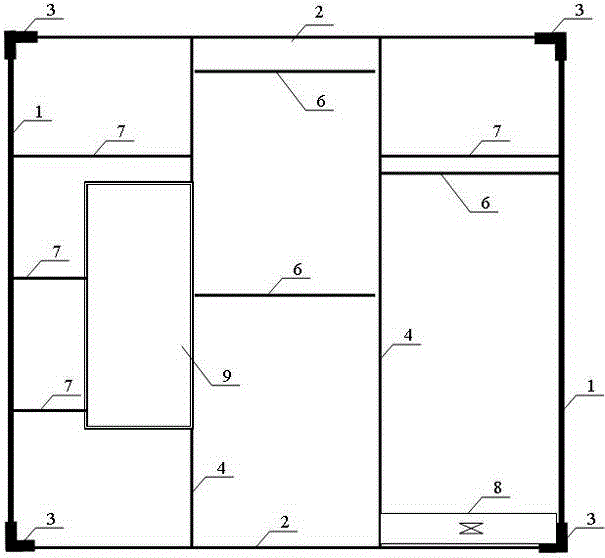

Iron sleeve environment-friendly closet

InactiveCN104510183ASolve the problems existing in the known technologyAchieved goalsWardrobesRigid cabinetsEnvironmental resistanceEngineering

The invention discloses an iron sleeve environment-friendly closet. According to the iron sleeve environment-friendly closet, a sleeve made of iron is produced outside a framework; the external structure of the closet consists of four front and rear outer columns (1) and four upper and down beams (2) and four pairs of fasteners (3); according to the internal structure of the closet, four inner columns (4) are arranged in the closet and are connected with the upper and down beams (2); the beams (2) and the inner columns (4) are tightly fixed by screws and sealing nuts; a short beam (5), a clothes rail (6) and a clothes hanger (7) are connected by tightly fixing the inner and outer columns and the short beam (5); a drawable box (8) can be drawable on angle steel; and an angle steel handle is arranged on the inner and outer columns (1). The internal structure of the closet is changed along with the changes on shapes, so that the clothes hanger (7), the clothes rail (6), the drawable box (8) and a lens frame (9) are moved to reasonable positions along with the changes of the shapes. The closet is provided with six doors which are respectively connected to four columns in the front of the closet by hinges, patterns on the doors of the closet are in thousands of attractive shapes which are changed at any time.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

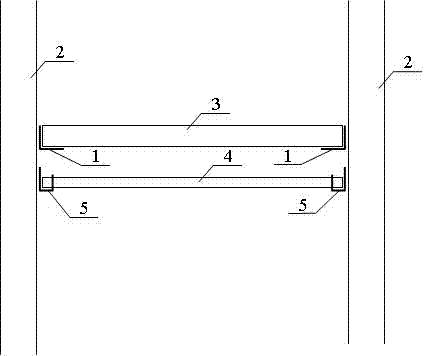

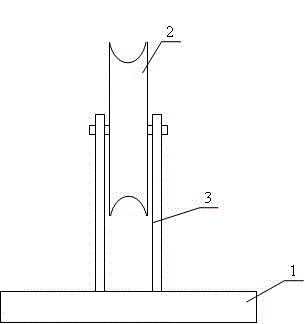

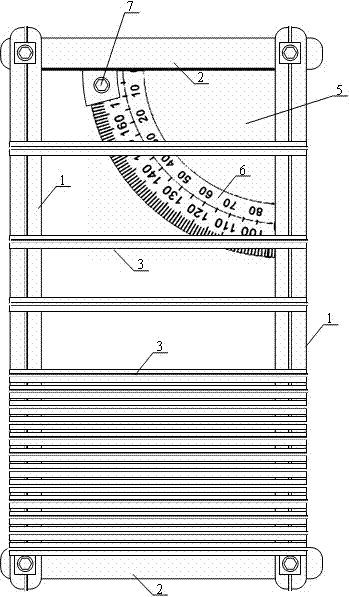

One-time-cutting large material measuring device

InactiveCN107971827ASolve the problems existing in the known technologyAchieved goalsMeasurement/indication equipmentsStructural engineeringVertical angle

The invention discloses a one-time-cutting large material measuring device. According to the one-time-cutting large material measuring device, two pieces of angle steel serve as a main material support (1), the two sides of the main material support (1) are each provided with two vertical column supports (2) and two lining supports (3), and thus two triangular platforms are formed; pieces of connecting angle steel (4) are arranged on the upper portions and the lower portions of the vertical column supports (2) correspondingly; and a piece of U-shaped connecting angle steel (5) is further arranged below the triangular platforms. A baffle (6) is arranged on the platforms, and movable frames (7) are arranged on the positions, below the baffle (6), of the angle steel; positioning clamps (8) are arranged on the movable frames; the movable frames and the positioning clamps are used for keeping the vertical angle of the baffle and the platforms; each material head abuts against the baffle; two flat rods (9) used for receiving cut materials are further arranged on the platforms, one of the flat rods (9) is arranged on the platform not away from a cutting bed, and the other flat rod (9) isarranged on the movable frames (7) of the baffle (6); and the height of each flat rod (9) is consistent with that of a rubber skin on the cutting bed, and the materials cut at a time are all on the flat rods.

Owner:广安市速创科技有限公司

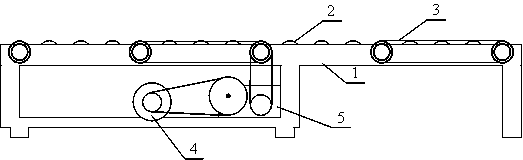

Large-scale cutting machine with one-step cutting function

InactiveCN107971554ASolve the problems existing in the known technologyAchieved goalsTube shearing machinesShearing machine accessoriesEngineeringMachine tool

The invention discloses a large-scale cutting machine with a one-step cutting function. The cutting machine is composed of two girders (1) which are connected with a cross beam side by side in a welding mode, four columns (2) are arranged at the four ends of the girders correspondently, the four columns (2) are installed on walls in the room and are connected with the girders (1) in a welding mode; each of the girders (1) is more than ten meters in length, and the girders (1) are preferably designed on a girder of a house in a newly-built factory building; hanging type machine bases (3) are arranged below the middles of the girders, and motors (4) are arranged in the middles of the machine bases (3); and shafts (5) are arranged at the bottommost ends of the machine bases, cutting sheets (6) are arranged at one ends of the shafts (5), belt discs (7) are arranged at the other ends of the shafts (5), and the belt discs (7) are connected with the belt discs (7) of the motors (4) through belts. The cutting machine does not occupy any space on the ground, on the ground; materials are completely cut under the cutting machine through a cutting machine tool.

Owner:广安市速创科技有限公司

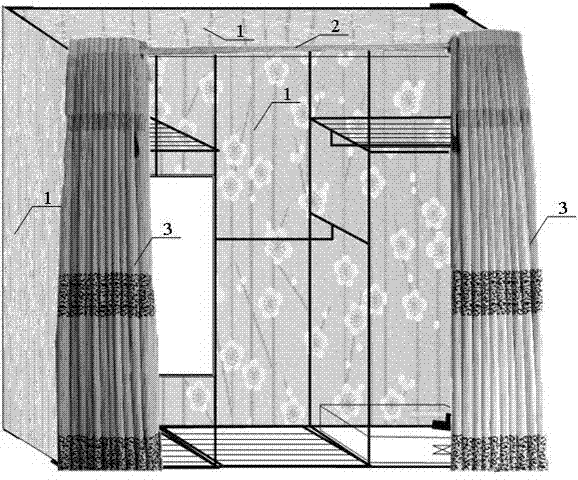

Clothes cover

InactiveCN104510202ASolve the problems existing in the known technologyAchieved goalsFurniture partsCurtainsEngineeringTextile

The invention discloses a clothes cover in a cloth environment-friendly wardrobe. The clothes cover is made of beautiful curtain fabric; according to the clothes cover, left, right, rear and upper sides are connected to form a cover (1) to cover the left, right, rear and upper sides of the wardrobe; only the front side is remained; the upper end of the front side is provided with a steel pipe (2) for hanging wardrobe door curtains; the wardrobe door curtains (3) are divided into left and right pieces; the height of the wardrobe door curtains (3) is equal to the height of the wardrobe body, and the width of the wardrobe door curtains (3) is equal to the size of the wardrobe body; the two pieces of the wardrobe door curtains (3) are equal to double the size of the wardrobe body; the edge of the cover (1) is clamped on a door frame by using a special plate clamp.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

Air blower with bent nozzle

InactiveCN107549975ASolve the problems existing in the known technologyAchieved goalsHair dryingEngineeringAir blower

The invention discloses an air blower with a bent nozzle. An existing air outlet nozzle of an air blower is changed into a bent nozzle (1) of the air blower; a machine body (2) is unchanged, so use isconvenient; when the air blower is used in winters, inlet air does not freeze hands; an air inlet (3) is re-disposed around the tail of the air blower; and a switch handle (4) is re-disposed at the tail part.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

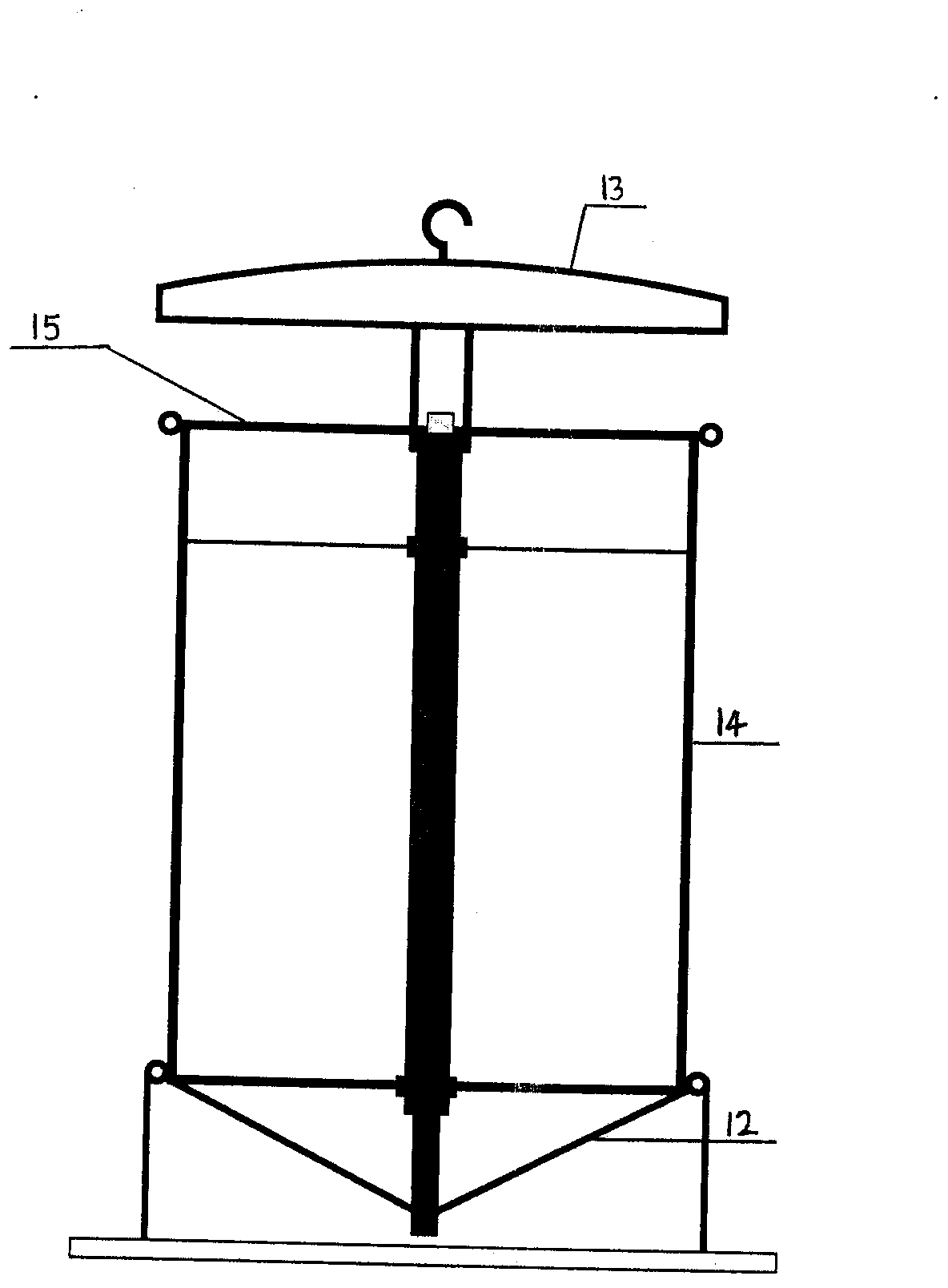

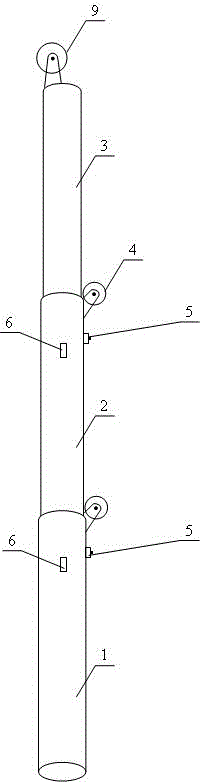

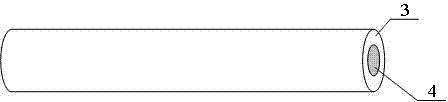

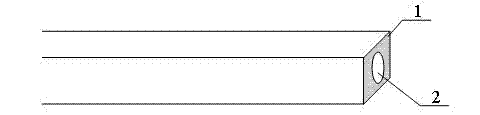

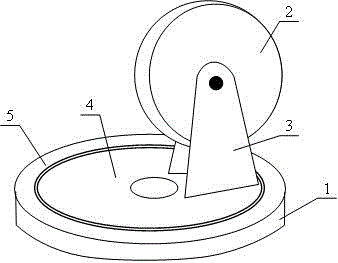

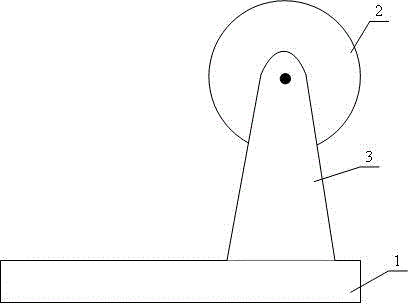

Pipe body telescopic derrick (rotary pulley)

InactiveCN106285174ASolve the problems existing in the known technologyAchieved goalsTowersPetroleum engineeringPulley

The invention discloses a pipe body telescopic derrick (rotary pulley); the rotary pulley is arranged on a derrick top (1), and can keep the perpendicularity of a derrick top (1) hanger steel wire rope; a pulley (2) and a pulley seat (3) are arranged on one side of a bearing inner ring (4); a bearing outer ring (5) and the derrick top (1) are tightly matched and connected; centers of a pulley groove and the derrick are on a same straight line; if the hanger needs the derrick to shift to certain direction, the rotary pulley will automatically rotate to said direction.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

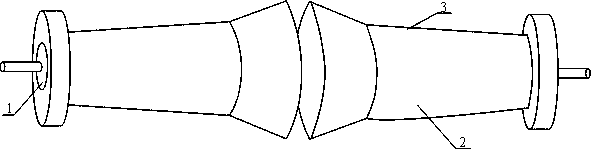

Drum-type shoe washing machine

InactiveCN108143379ASolve the problems existing in the known technologyAchieved goalsFootwear cleanersBristleWastewater

The invention discloses a drum-type shoe washing machine. According to the shoe washing machine, a drum (2) is driven via a casing-rotating motor (1); an upright-bristle inserting base (3) is arrangedon the drum (2); the middle of the drum is larger than two ends; flat-inserted bristle discs on two ends are as large as the middle section of the drum; an upright-inserted bristle hole (3) is kept in the middle section of the drum, and flat-inserted bristle holes (4) are kept in two ends of the drum; upright bristles (3) are in charge of washing and brushing shoe bottoms, and flat bristles (4) are used for washing and brushing parts around the shoe bottoms; and a collar (5) is additionally arranged on the middle section of the drum, and the collar is used for washing and brushing heels of high-heeled shoes. A water spraying unit is arranged on a machine shell, so that water is directly sprayed on the bristles, and wastewater obtained from washing shoes drops into a water jar under the machine shell; and water drainage in the water jar gets into communicating connection with an indoor drainage pipe.

Owner:唐文碧

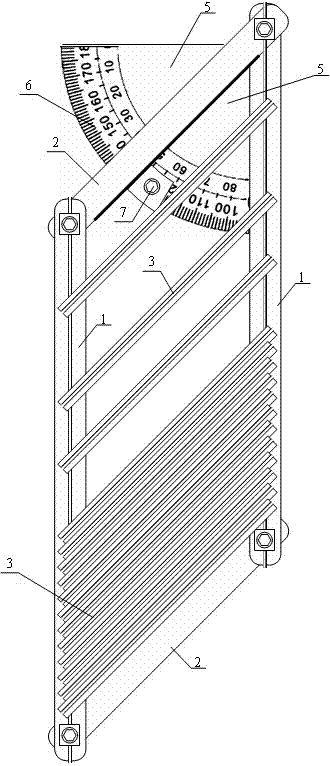

Large-scale multi-angle template allowing one-step cutting

InactiveCN107971560ASolve the problems existing in the known technologyAchieved goalsShearing machine accessoriesSteel platesSheet steel

The invention discloses a large-scale multi-angle template allowing one-step cutting. The large-scale multi-angle template is characterized by being arranged on the upper surface of a cutting machinetool through three pieces of transverse square steel, two pieces of inner channel steel (1) are arranged on the square steel, two pieces of angle steel (2) are arranged at the two ends of the surfaceof each piece of inner channel steel (1) respectively, and the angle steel (2) and the inner channel steel (1) are connected with each other through screws to form a rectangular ring, wherein the angle of the rectangular ring can be randomly changed; the two ends of the surface of each piece of inner channel steel (1) are correspondently provided with adjusting screws; a plurality of pieces of three-fork steel (3) are arranged on the two pieces of inner channel steel (1), fasteners (4) are arranged under the three-fork steel (3), and caps of the fasteners (4) face downwards; nail rods are clamped among the the three-fork steel (3) and connected with the three-fork steel (3) in a welding mode, and the caps of the fasteners (4) are arranged in grooves of the inner channel steel (1); and a steel plate (5) is welded to one connecting angle, a protractor (6) is arranged on the steel plate (5), and a positioning clamp (7) is arranged between the steel plate (5) at the connecting angle and the angle steel which is arranged on the steel plate (5).

Owner:广安市速创科技有限公司

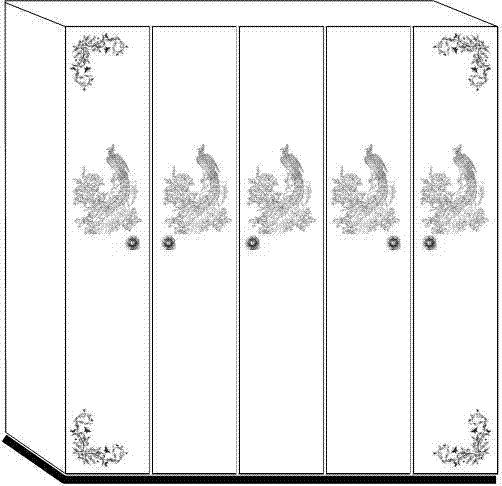

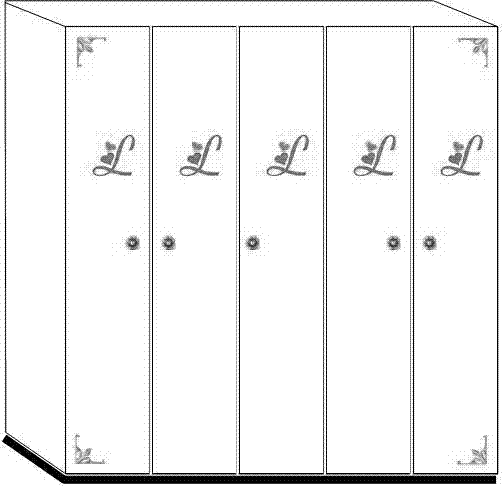

Assembly and disassembly type environment-friendly wardrobe (environment-friendly aluminum wardrobe)

InactiveCN105326225ASolve the problems existing in the known technologyAchieved goalsWardrobesDoors/windowsFront edgeTyping environment

The invention discloses an environment-friendly aluminum wardrobe made of aluminum plates. The cross section of each aluminum plate is latticed, male penetration pins and female insertion grooves for connecting each aluminum plate with the corresponding aluminum plate are formed at two edges of each aluminum plate respectively, and the aluminum plates are connected through the penetration pins. A wardrobe body is formed by connecting a left aluminum plate (1), a right aluminum plate (1) and two inner aluminum plates (2) with a bottom aluminum plate (3) and a top aluminum plate (4) and connecting three back aluminum plates (5) with the aluminum plates (1), and the top and the bottom of the wardrobe body are connected with the top aluminum plate (4) and the bottom aluminum plate (3) respectively. Clothes holding boards (6), a drawing box (7), clothes rails (8) and a mirror bracket (9) are connected to the corresponding aluminum plates (1) and the corresponding aluminum plates (2), and wardrobe doors are also connected to front edges of the aluminum plates (1 and 2). The appearance patterns of the wardrobe doors are diversified in design, and more attractive styles are transformed and updated at any time.

Owner:YUECHI LICHENG ENVIRONMENT PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com