Green brick forming machine

A molding machine and adobe technology, which is applied in the direction of ceramic molding machines, manufacturing tools, molds, etc., can solve the problems of wasting power resources and human resources, increasing construction costs and operating risks of enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

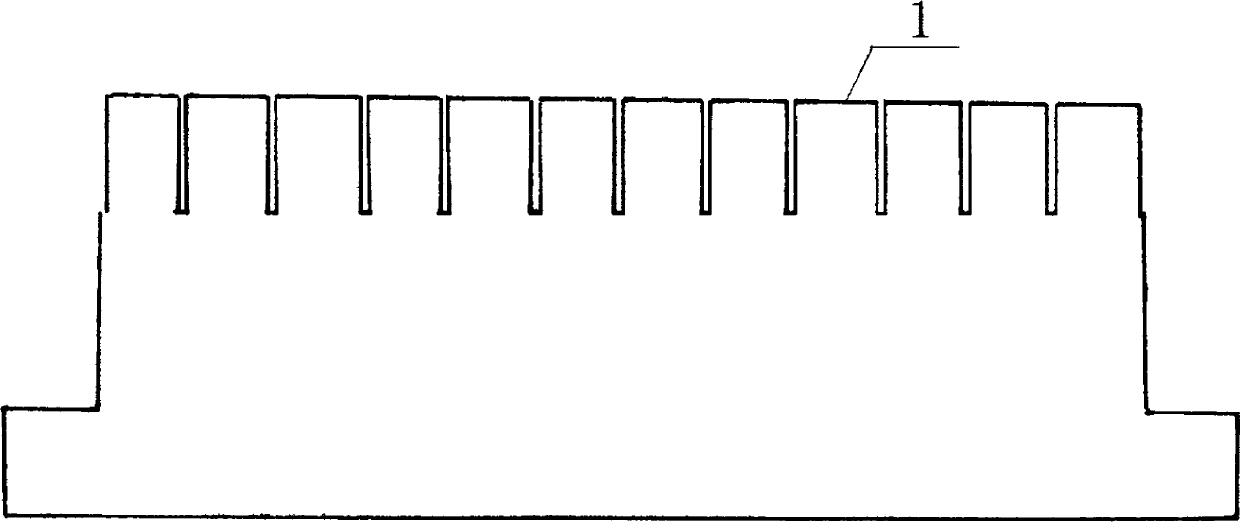

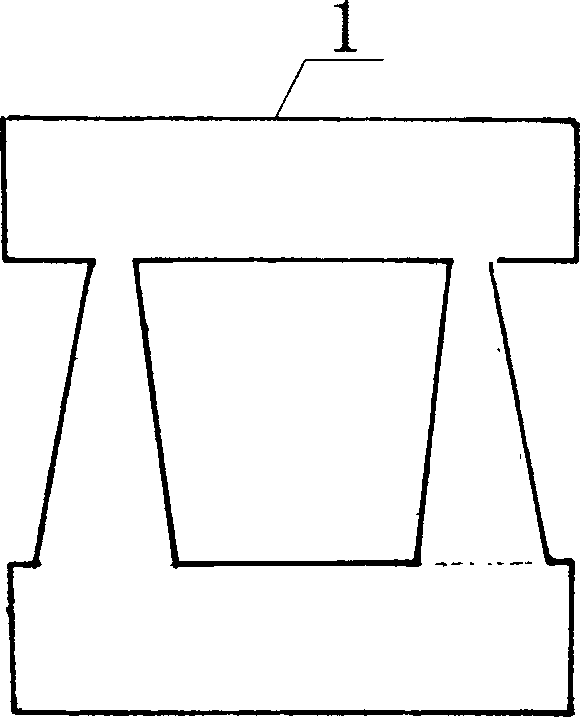

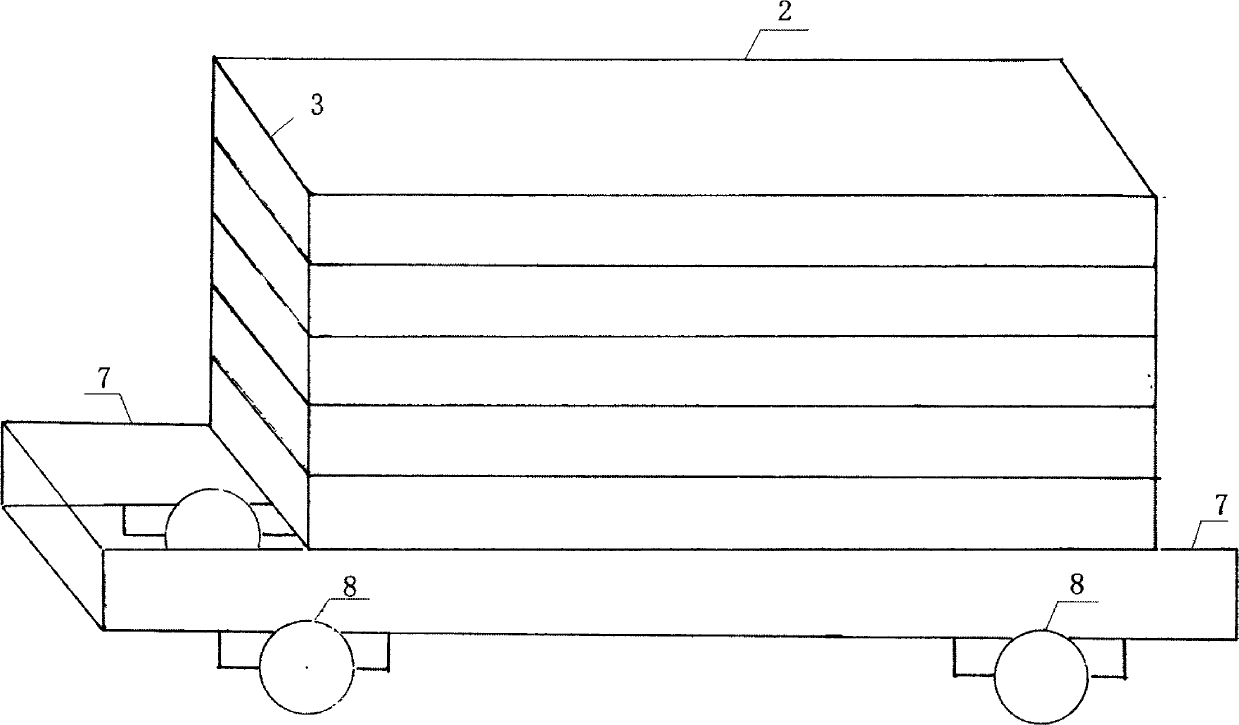

[0011] Such as figure 1 As shown, in order to improve efficiency and reduce costs, adobe production will rely on the adobe forming machine designed in this scheme. The adobe forming machine is composed of 20 base plates 1 squares and 20 wall panels 2, 3, forming a 4.66-meter-long A rectangular parison box with a width of 0.7 meters and a height of 0.58 meters can accommodate 1,200 bricks.

[0012] The blank box wallboard is divided into rectangular wallboard 2 and short square wallboard 3. The short square wallboard 3 is provided with a hanging buckle 4 lock pin 5 and a box body adjustment screw 6. The width of the wallboard is 5 mm (5 mm) less than the width of the brick. mm is the saw road), relying on the strengthening device to maintain the distance between the wall panels and the wall panels.

[0013] The blank box is combined and can be disassembled. There are balls on the top of the blank box frame 7, and the blank box bottom plate 1 can slide on it. There are four whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com