Vehicle sleeping platform (scissors form)

A scissor-type, sleeping platform technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of loading, wasting human resources, wasting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

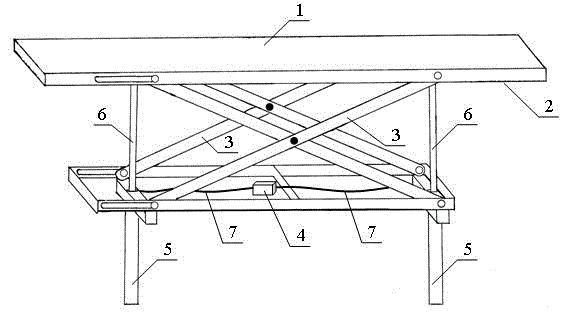

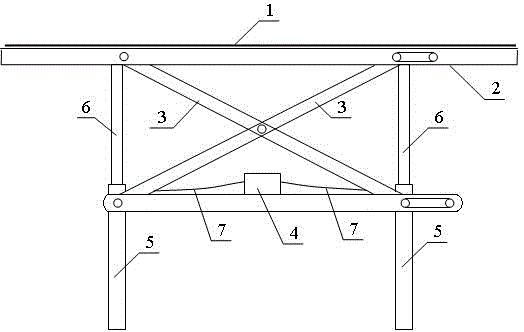

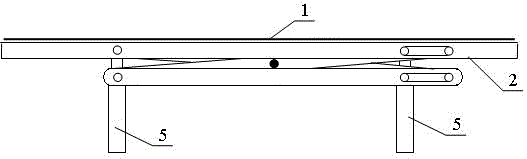

[0010] like figure 1 As shown in the figure, the loading of goods in the logistics transfer station should be designed with the help of this scheme to design the underground lifting sleeping car platform. The table top 1 of the sleeping car platform is designed with a steel plate table 1 whose length and width exceed the length and width of the truck and is level with the ground. Below the table 1 is a reinforcement device 2 It is welded and connected to the table top 1. Below the reinforcement device 2 is a scissors-type lifting device 3. The middle of the scissors-type lifting device 3 is a hydraulic press 4. The two ends of the scissors-type lifting device 3 are provided with a hydraulic cylinder 5, a hydraulic rod 6, and a hydraulic pipe 7. The hydraulic machine 4 is connected, and the other end is connected with the hydraulic cylinder 5. In this way, the lifting device of the sleeping car platform cooperates with the supporting force of the hydraulic device to complete th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com