Pipe body telescopic holding pole

A telescopic and pole-holding technology, which is applied in the direction of building types, buildings, towers, etc., can solve problems such as difficulty in standing, aggravating the construction cost and operation risk of enterprises, and difficulty in reaching heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

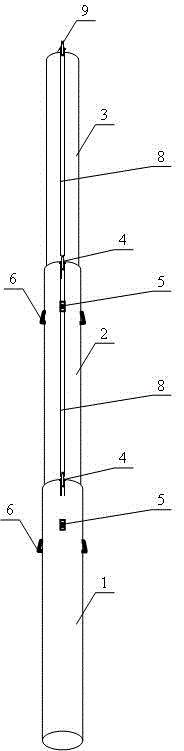

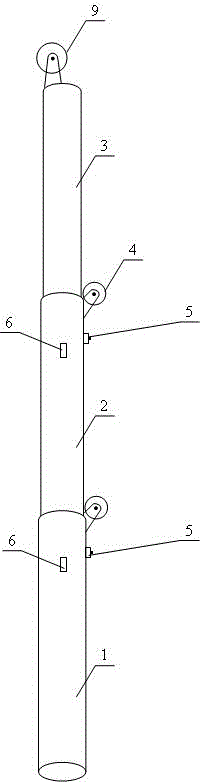

[0012] like figure 1 As shown, a telescopic holding pole with a tubular body, the holding pole is composed of three seamless steel pipes of different sizes, the outer, the middle, and the inner suit. The outer holding pole 1 is provided with a telescopic wire rope pulley 4 next to the upper end, and a lock is provided one meter below the pulley 4. Bolt 5, below the locking bolt 5 is provided with the self-connecting outer valve 6 of holding bar.

[0013] The lower end of the middle pole 2 is a self-connecting internal valve 7, and the middle pole 2 is provided with a groove 8 from top to bottom that can accommodate the telescopic steel wire rope. The upper opening of the groove 8 is not sealed, and the lower opening is to be sealed. 9. It is on the same line as the groove 8. The groove 8 and the lock bolt 5 are guided and positioned. The middle pole 2 is one meter longer than the outer pole 1, which is one meter longer than the outer pole 1. The design is the same.

[0014] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com