One-time-cutting large material measuring device

A one-size-fits-all, material-measurement technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of aggravating the operation risk of enterprises or individual construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

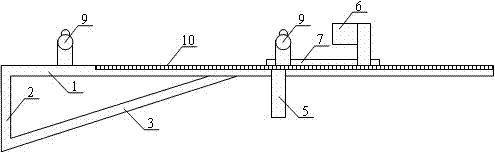

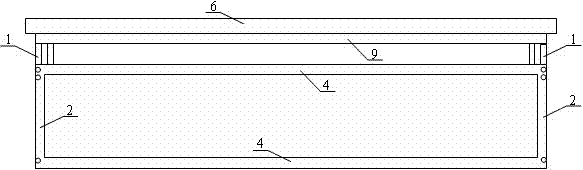

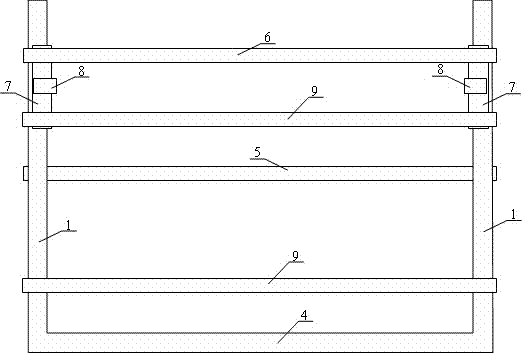

[0011] Such as figure 1 As shown, if a large amount of material needs to be cut, it is necessary to use the one-size-fits-all large-scale feeder designed by this scheme. The feeder is made of two angle steels as the main material support 1, and two column supports 2 are provided on each side. There are two lining brackets 3 on both sides to form two triangular platforms. The upper and lower ends of the column bracket 2 are respectively provided with connecting angle steel 4 to connect the two triangles together. There is also a concave connecting angle steel 5 under the triangular platform. The connecting angle steel 5 is to make way in the platform, and the mobile frame 7 below the baffle plate 6 is positioned according to the length of the material, and will move back and forth inside, such as image 3 shown.

[0012] A baffle plate 6 is arranged above the platform, and the angle steel below the baffle plate 6 is provided with a mobile frame 7, and a positioning card 8 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com