Hollow brick wall construction mode

A technology for closing bucket walls and buildings, which is applied in construction, building components, building structures, etc., and can solve problems such as increasing construction costs of enterprises, not reducing weight, and reducing walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

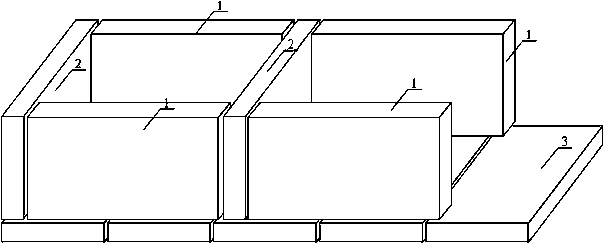

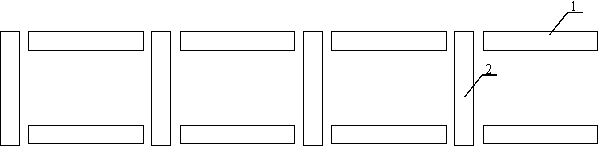

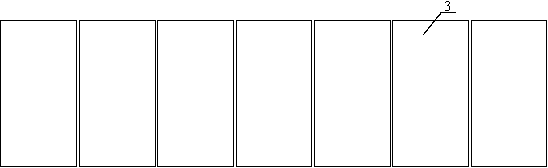

[0011] Such as figure 1 As shown, high-rise buildings need to reduce the cost and reduce the weight by means of the Guandou wall construction method designed in this scheme. Various thicknesses, for example, the wall can be built into 21 cm, 19 cm, or 18 cm. The bricks are also newly designed. One piece, and another 2 pieces of Guandou bricks are built to form a bucket, such as figure 2 As shown, just such a bucket is connected with a bucket and the ground is built, and the back two rows of cover bucket bricks 3 are built after a row is full, and the ground is laid flat next to each other, as image 3 As shown, the next row is the same as the previous row.

[0012] The method of building a wall of more than ten centimeters is to displace a vertical bucket brick 1 on one side, and a closed bucket brick 2 obliquely. The bucket wall has the function of heat and sound insulation. The defects of the prior art are solved, and the construction cost is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com