Workshop pallet

A workshop and off-board technology, applied in the direction of transportation and packaging, loading/unloading, etc., can solve the problems of long and difficult loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

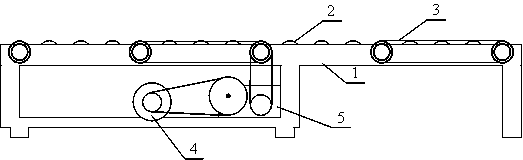

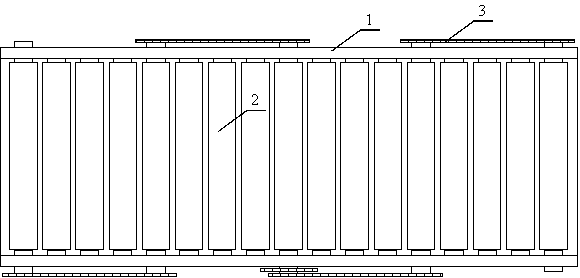

[0011] Such as figure 1 As shown, to use machines instead of labor to load and unload and carry goods with coolies, it is necessary to rely on the workshop off-board designed in this scheme. The workshop off-board is the starting point off-board, and the goods are changed from zero to whole in the way of sliding transmission, sliding from the workshop to the docking port of the forklift, docking with the forklift loading and unloading off-board and with the transfer Off-board docking.

[0012] The workshop off-disc is installed between the workshop and the fork lane by a rectangular frame 1. The specific length depends on the distance between the workshop and the fork lane or the distance between the transfer off-disk. The frame 1 is partly inside the workshop wall and partly on the wall. Outside, the width of the frame 1 is the length of the goods bundled into a large piece. There are dozens of rollers 2 inside the frame 1. Each roller 2 is equipped with bearings and bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com